2.4.5.9 Mechanical Brake Control

In hoisting/lowering applications, it is necessary to be able

to control an electro-mechanical brake:

•

Control the brake using any relay output or

digital output (terminal 27 or 29).

•

Keep the output closed (voltage-free) as long as

the Adjustable frequency drive is unable to

‘support’ the motor, for example due to the load

being too heavy.

•

Select Mechanical brake control [32] in par. 5-4*

for applications with an electro-mechanical brake.

•

The brake is released when the motor current

exceeds the preset value in 2-20 Release Brake

Current.

•

The brake is engaged when the output frequency

is less than the frequency set in 2-21 Activate

Brake Speed [RPM]or 2-22 Activate Brake Speed

[Hz], and only if the Adjustable frequency drive

carries out a stop command.

If the Adjustable frequency drive is in alarm mode or in an

overvoltage situation, the mechanical brake immediately

cuts in.

In the vertical movement, the key point is that the load

must be held, stopped, controlled (raised, lowered) in a

perfectly safe mode during the entire operation. Because

the Adjustable frequency drive is not a safety device, the

crane/lift designer (OEM) must decide on the type and

number of safety devices (e.g., speed switch, emergency

brakes, etc.) to be used in order to be able to stop the

load in case of emergency or malfunction of the system,

according to relevant national crane/lift regulations.

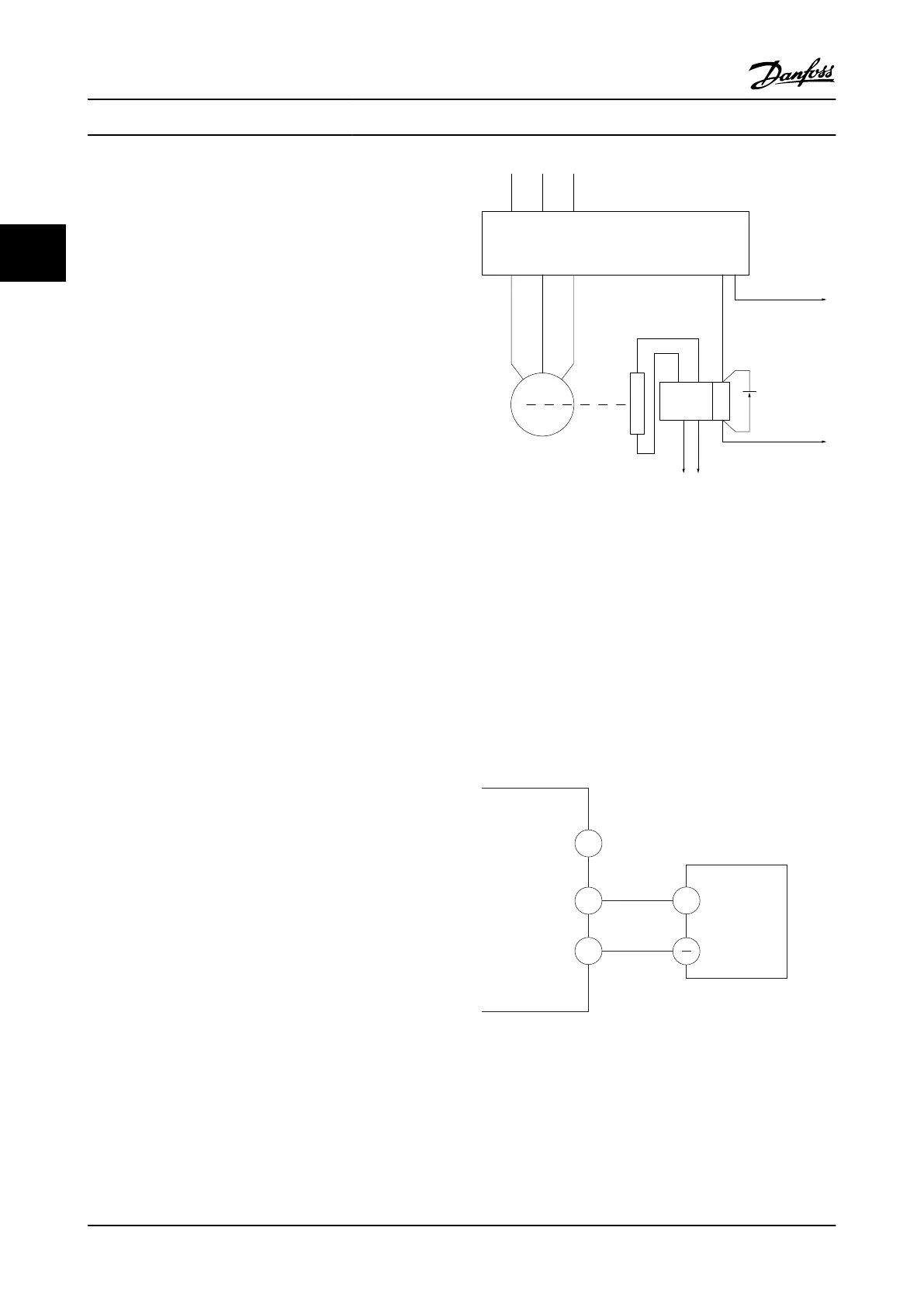

L1 L2 L3

U V W

02 01

A1

A2

130BA902.10

Drive

Output

relay

Command Circuit

220Vac

Mechanical

Brake

Shaft

Motor

Frewheeling

diode

Brake

380Vac

Output

Contactor

Input

Power Circuit

Figure 2.17 Connecting the Mechanical Brake to the Adjustable

Frequency Drive

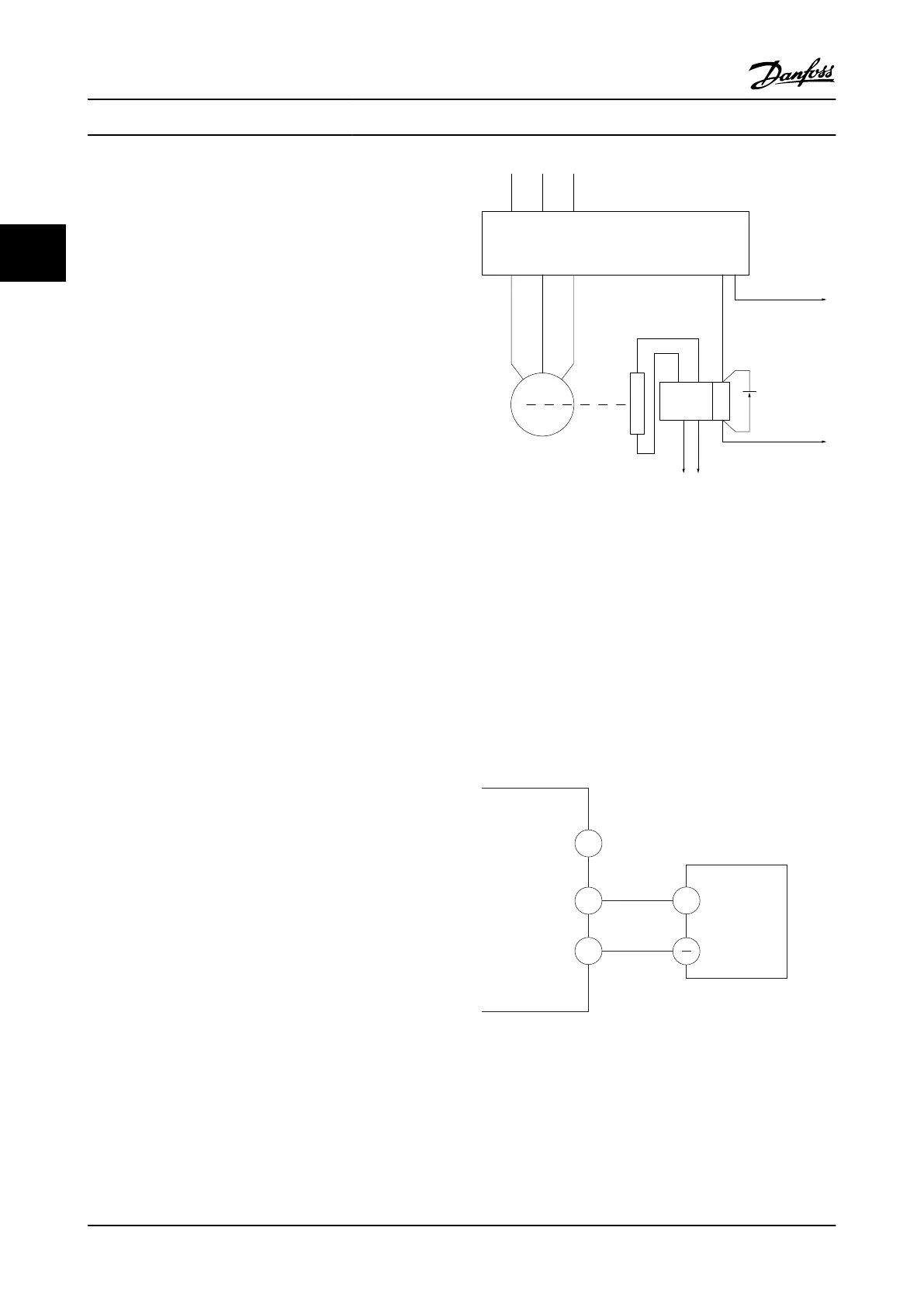

2.4.6

Serial Communication

Connect RS-485 serial communication wiring to terminals

(+)68 and (-)69.

•

A shielded serial communication cable is

recommended

•

See 2.4.2 Grounding Requirements for proper

grounding

61

68

69

+

130BB489.10

RS-485

Figure 2.18 Serial Communication Wiring Diagram

Installation

VLT

®

AutomationDrive Instruction

Manual

2-14 MG.33.AI.22 - VLT

®

is a registered Danfoss trademark

2

2

Loading...

Loading...