Bits no. 12-15 transfer parameter commands from master

to slave and return processed slave responses to the

master.

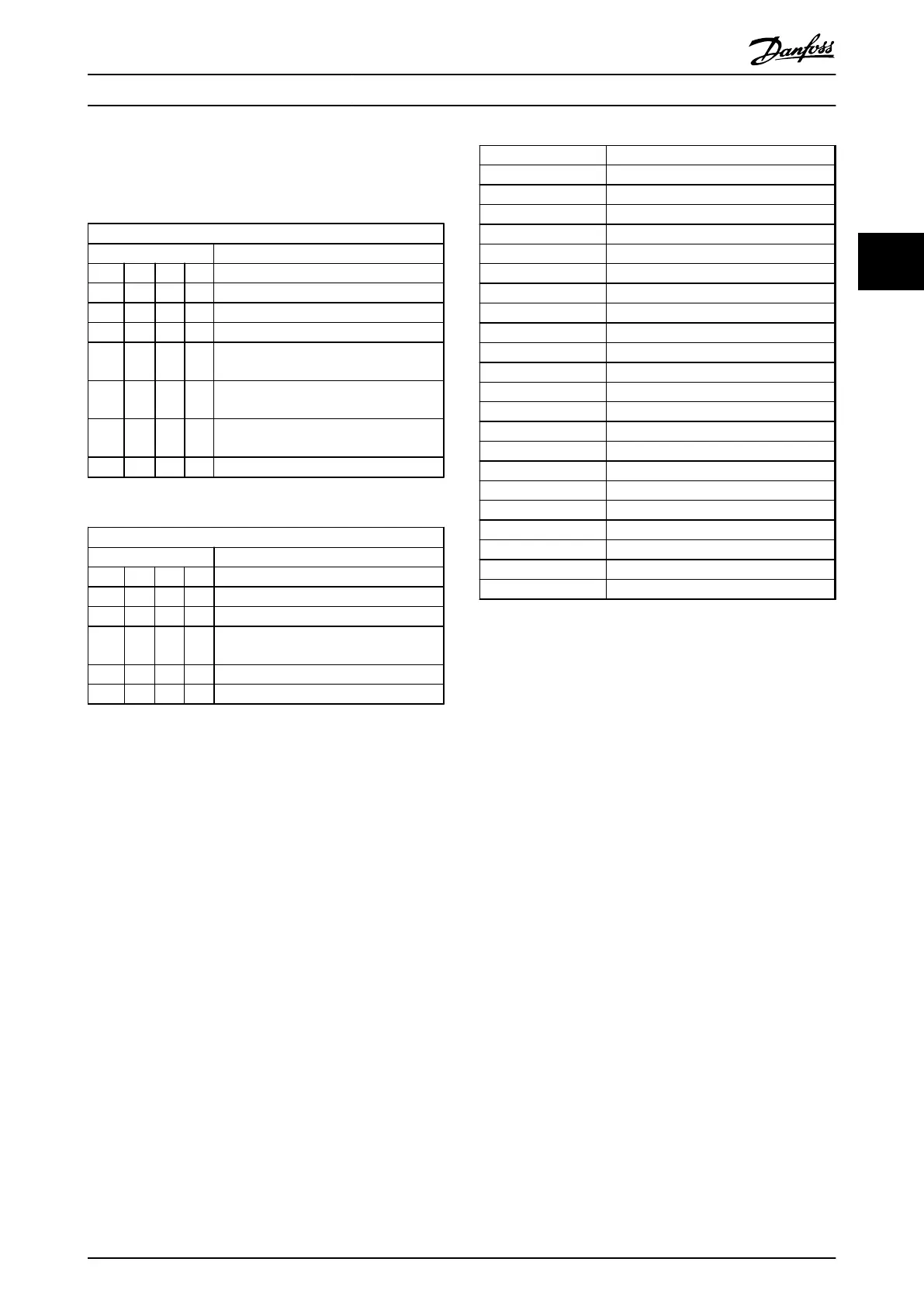

Parameter commands master ⇒ slave

Bit no. Parameter command

15 14 13 12

0 0 0 0 No command

0 0 0 1 Read parameter value

0 0 1 0 Write parameter value in RAM (word)

0 0 1 1 Write parameter value in RAM (double

word)

1 1 0 1 Write parameter value in RAM and

EEprom (double word)

1 1 1 0 Write parameter value in RAM and

EEprom (word)

1 1 1 1 Read text

Table 3.5 Parameter Commands

Response slave ⇒ master

Bit no. Response

15 14 13 12

0 0 0 0 No response

0 0 0 1 Parameter value transferred (word)

0 0 1 0 Parameter value transferred (double

word)

0 1 1 1 Command cannot be performed

1 1 1 1 text transferred

Table 3.6 Response

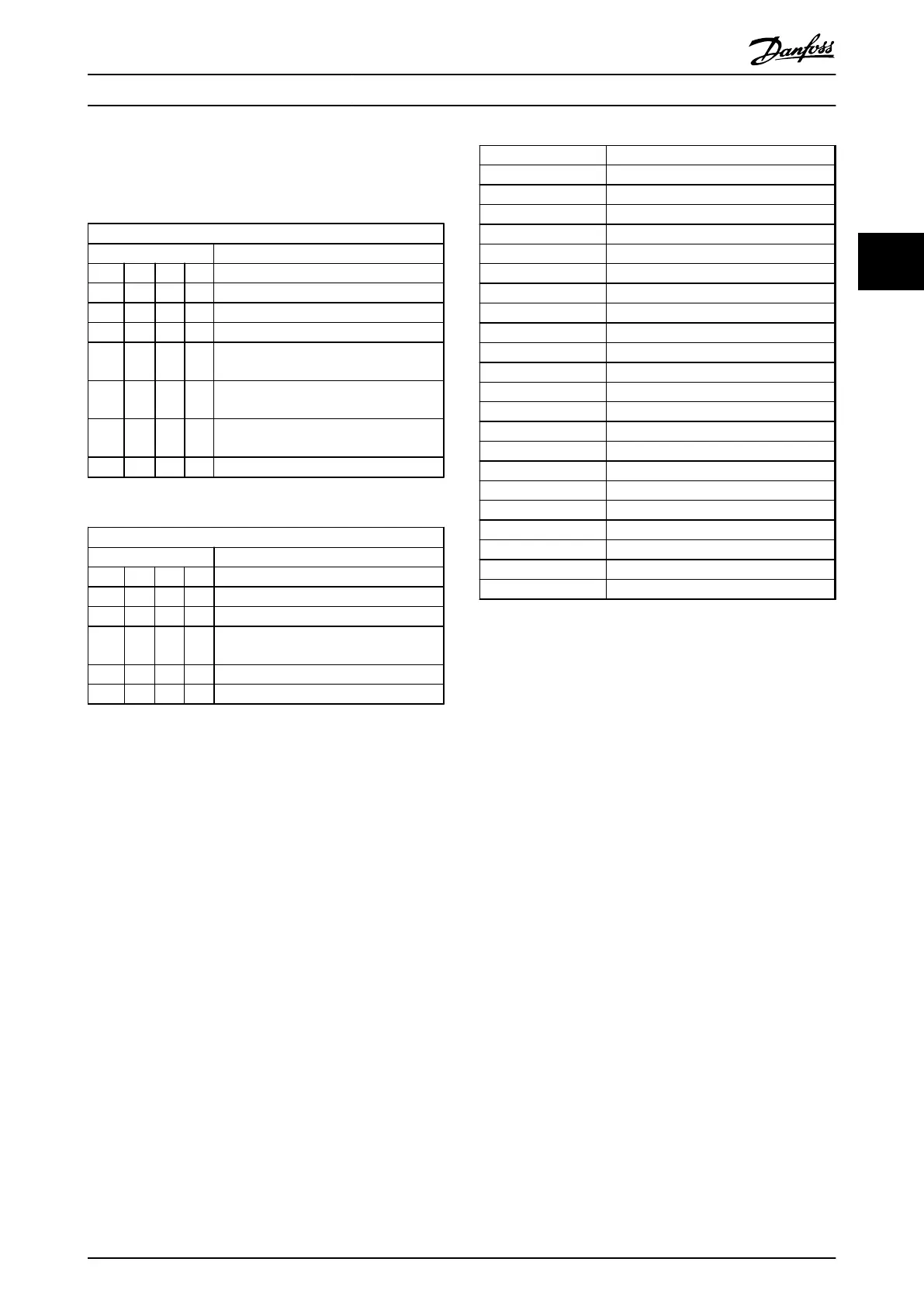

If the command cannot be performed, the slave sends this

response:

0111 Command cannot be performed

- and issues the following fault report in the parameter

value:

Error code

FC+ Specification

0 Illegal Parameter Number

1 Parameter cannot be changed.

2 Upper or lower limit exceeded

3 Subindex corrupted

4 No Array

5 Wrong Data Type

6 Not used

7 Not used

9 Description element not available

11 No parameter write access

15 No text available

17 Not while Running

18 Other error

100

>100

130 No bus access for this parameter

131 Write to factory set-up not possible

132 No LCP access

252 Unknown viewer

253 Request not supported

254 Unknown attribute

255 No error

Table 3.7 Slave Report

3.4.8

Parameter Number (PNU)

Bits no. 0-11 transfer parameter numbers. The function of

the relevant parameter is defined in the parameter

description in the VLT

®

AutomationDrive FC 360

Programming Guide.

3.4.9

Index (IND)

The index is used together with the parameter number to

read/write-access parameters with an index, for example,

15-30 Alarm Log: Error Code. The index consists of 2 bytes;

a low byte, and a high byte.

Only the low byte is used as an index.

3.4.10

Parameter Value (PWE)

The parameter value block consists of 2 words (4 bytes),

and the value depends on the defined command (AK). The

master prompts for a parameter value when the PWE block

contains no value. To change a parameter value (write),

write the new value in the PWE block and send from the

master to the slave.

When a slave responds to a parameter request (read

command), the present parameter value in the PWE block

is transferred and returned to the master. If a parameter

RS-485 Installation and Set...

VLT

®

AutomationDrive FC 360 Design Guide

MG06B202 - VLT

®

is a registered Danfoss trademark 45

3

3

Loading...

Loading...