21

I-Class Mark II Maintenance Manual

Ad

ustments and Maintenance

2.4.1 Cleaning the Printhead

CAUTION

NEVER use a sharp object on the Printhead;

damage can result.

If print quality declines (symptoms can include non-compliant

bar codes or streaks in the image), the typical cause is debris

buildup on the printhead.

If not removed, debris buildup can result in permanent

damage.

Depending upon the media and settings most typically used,

different methods and materials are recommended for

cleaning the printhead, as detailed below.

Faulty Label: Streaks (e.g., white

lines) in the direction of print can

indicate a dirty or faulty printhead.

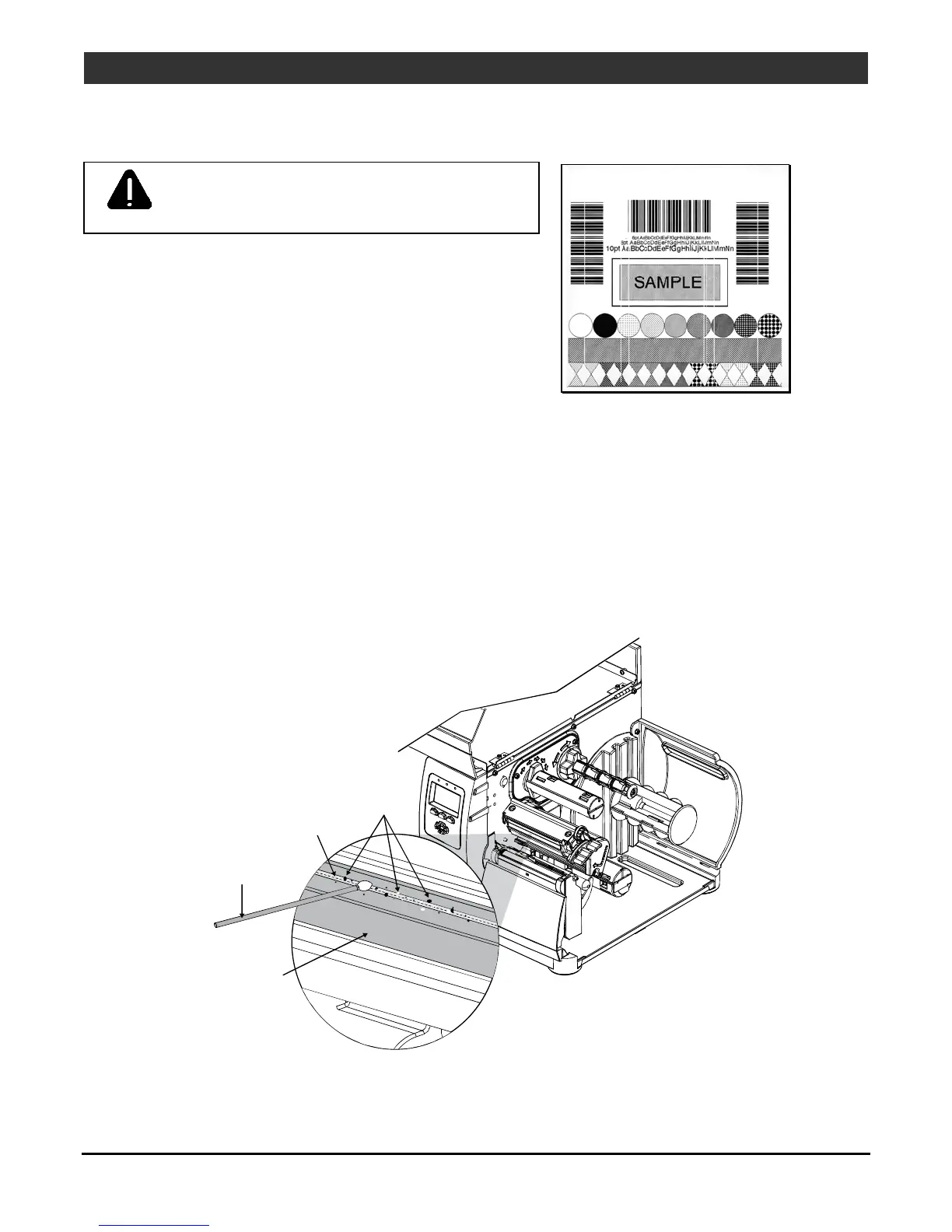

2.4.1.1 Cotton Swab Procedure

This cleaning method is recommended when using direct thermal media or thermal transfer media with a wax

ribbon.

1. Turn OFF and unplug the printer. Wait for the printhead to cool.

2. Raise the Printhead Assembly then remove the media (and ribbon, if installed). Using a Cotton Swab

moistened (not soaked) with isopropyl alcohol, gently wipe the Printhead and Burn Line clean.

Burn Line

Buildup

Printhead

Cotton Swab

3. Allow the printhead to dry.

4. Install media (and ribbon, if necessary). Lower and latch the Printhead Assembly. Close the cover. Plug in

and turn ON the printer. Run several sample labels and examine the print quality. If streaks are still

present, go to Section 2.4.1.2; otherwise, this completes the procedure.

Loading...

Loading...