Chapter 7 Motion Control ASDA-A2

Revision February, 2017 7-13

7.6 The Position Unit of PR Mode

The position data of PR mode is represented by PUU (Pulse of User Unit). It is also the proportion

between the controller position unit and the internal position unit of the servo drive, which is the so-

called electronic gear ratio of the servo drive.

1. The position unit of the servo drive (pulse): Encoder unit: 1280000 (pulse/rev), which will

not change.

2. User unit (PUU): The unit of the controller.

P pulse per revolution (PUU/rev), the gear ratio should set as:

GEAR_NUM (P1-44) / GEAR_DEN (P1-45) = 1280000 / P

7.7 Description of Register in PR Mode

1. Position register of PR mode: All is represented in PUU (Pulse of User Unit).

2. Command register (monitoring variable 064): Command termination register Cmd_E. It

represents the absolute terminal coordinate of position command.

3. Command output register (monitoring variable001): Cmd_O; it represents the absolute

coordinate from the current output command.

4. Feedback register (monitoring variable 000): Fb_PUU; it shows the absolute feedback

position of the motor.

5. Deviation register (monitoring variable 002): Err_PUU; it is the deviation between the register

from command output and feedback register.

6. In PR mode, either in operation or stop status, it satisfies the condition of Err_PUU = Cmd_O -

Fb_PUU.

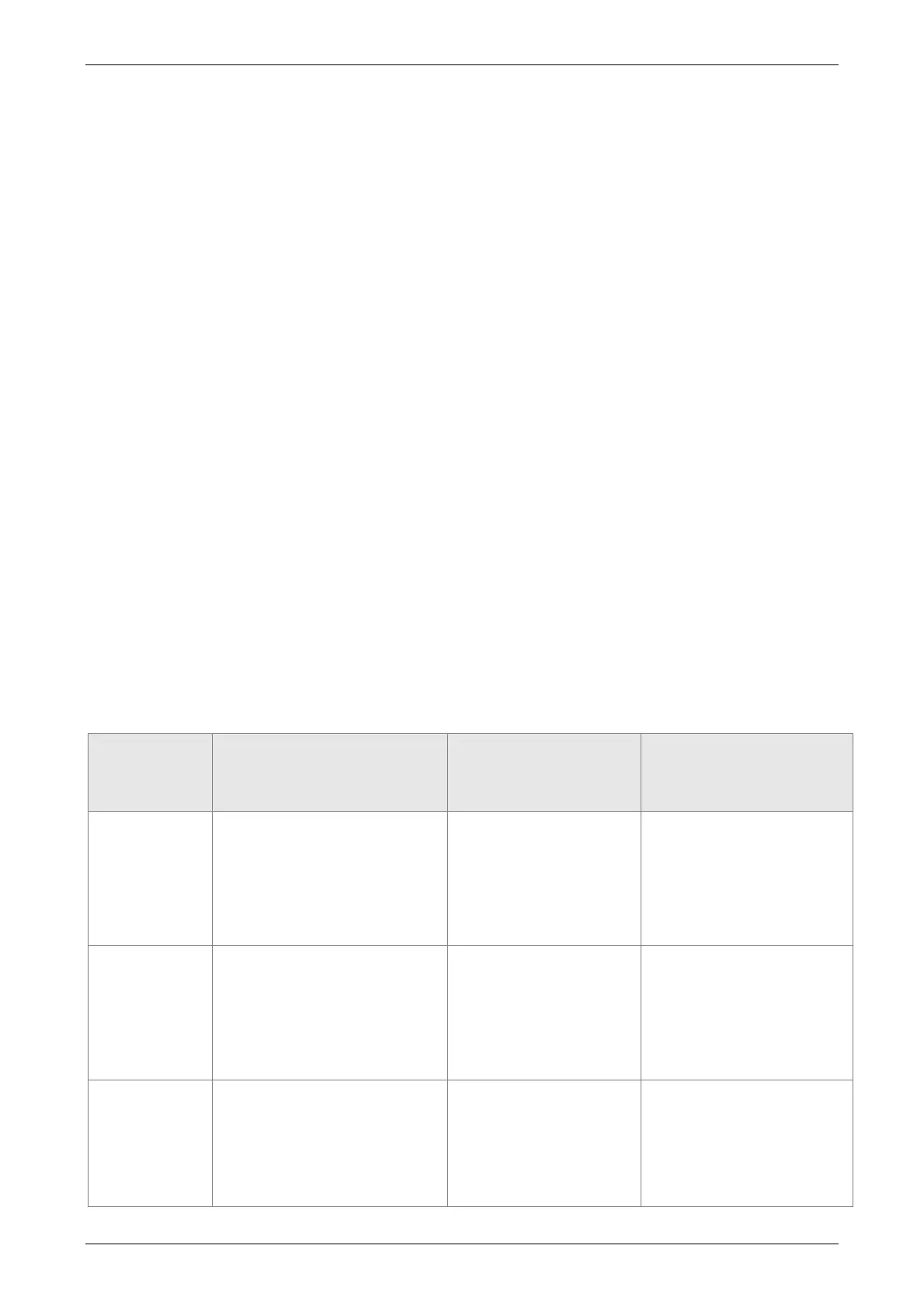

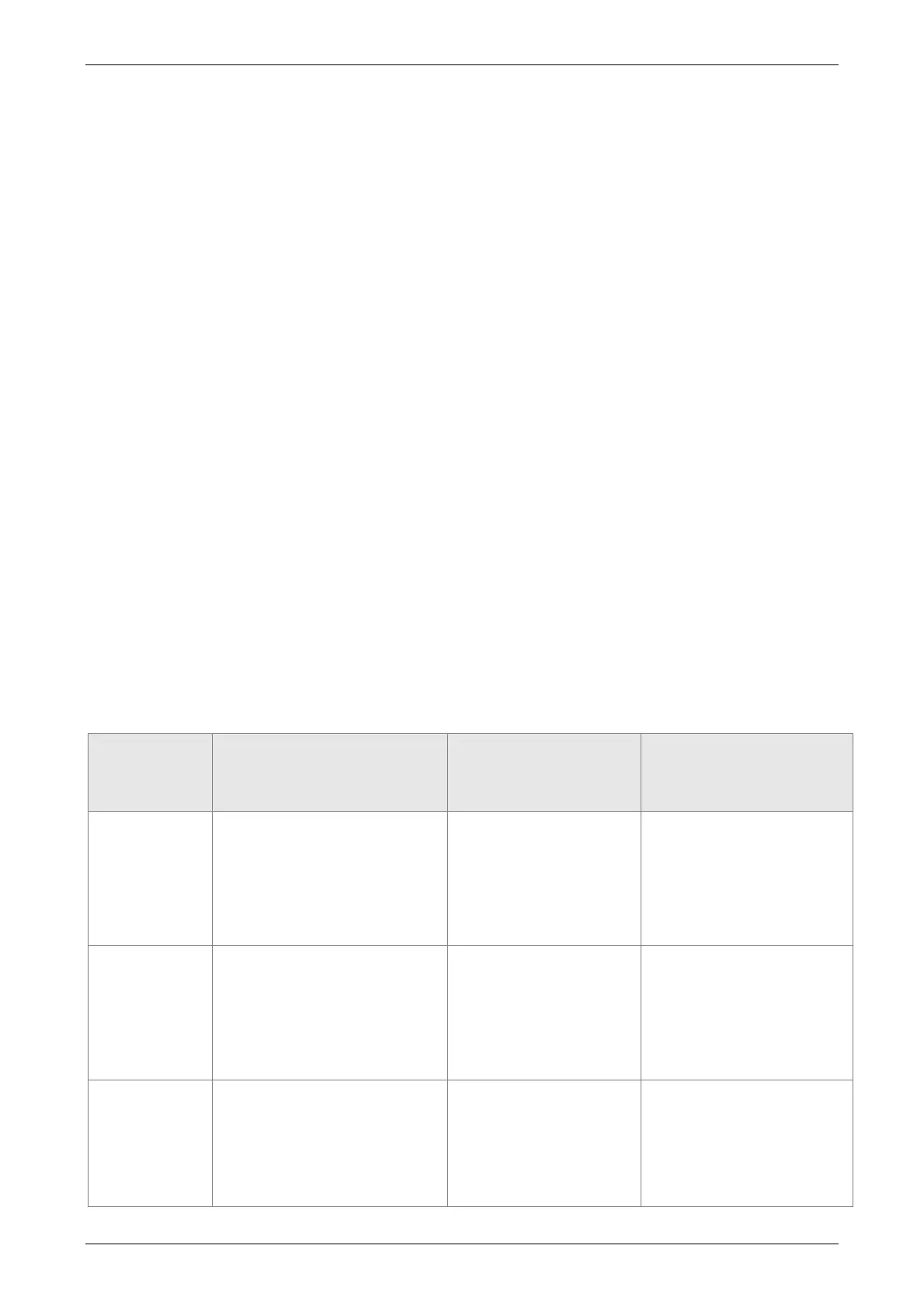

Influence brought by position command:

Type of

Command

When issuing the command

=>

=>When command is

executing=>

=> Command is

completed

Absolute

Positioning

Command

Cmd_E = command data

(absolute)

Cmd_O does not change.

DO.CMD_OK is OFF

Cmd_E does not

change.

Cmd_O continuously

output

...

Cmd_E does not change.

Cmd_O = Cmd_E

DO.CMD_OK is ON

Incremental

Positioning

Command

Cmd_E+= command data

(incremental)

Cmd_O does not change.

DO.CMD_OK is OFF

Cmd_E does not

change.

Cmd_O continuously

output

...

Cmd_E does not change.

Cmd_O = Cmd_E

DO.CMD_OK is ON

Issue the

command of

DI:STP to

stop the

command

Cmd_E does not change.

Cmd_O continuously output

DO.CMD_OK is

unchangeable

Cmd_E does not

change.

Cmd_O stops

according to the

deceleration curve

Cmd_E does not change.

Cmd_O = position after

stop

DO.CMD_OK is ON

Loading...

Loading...