Chapter 4 Parameters

VFD-EL-W

4-92

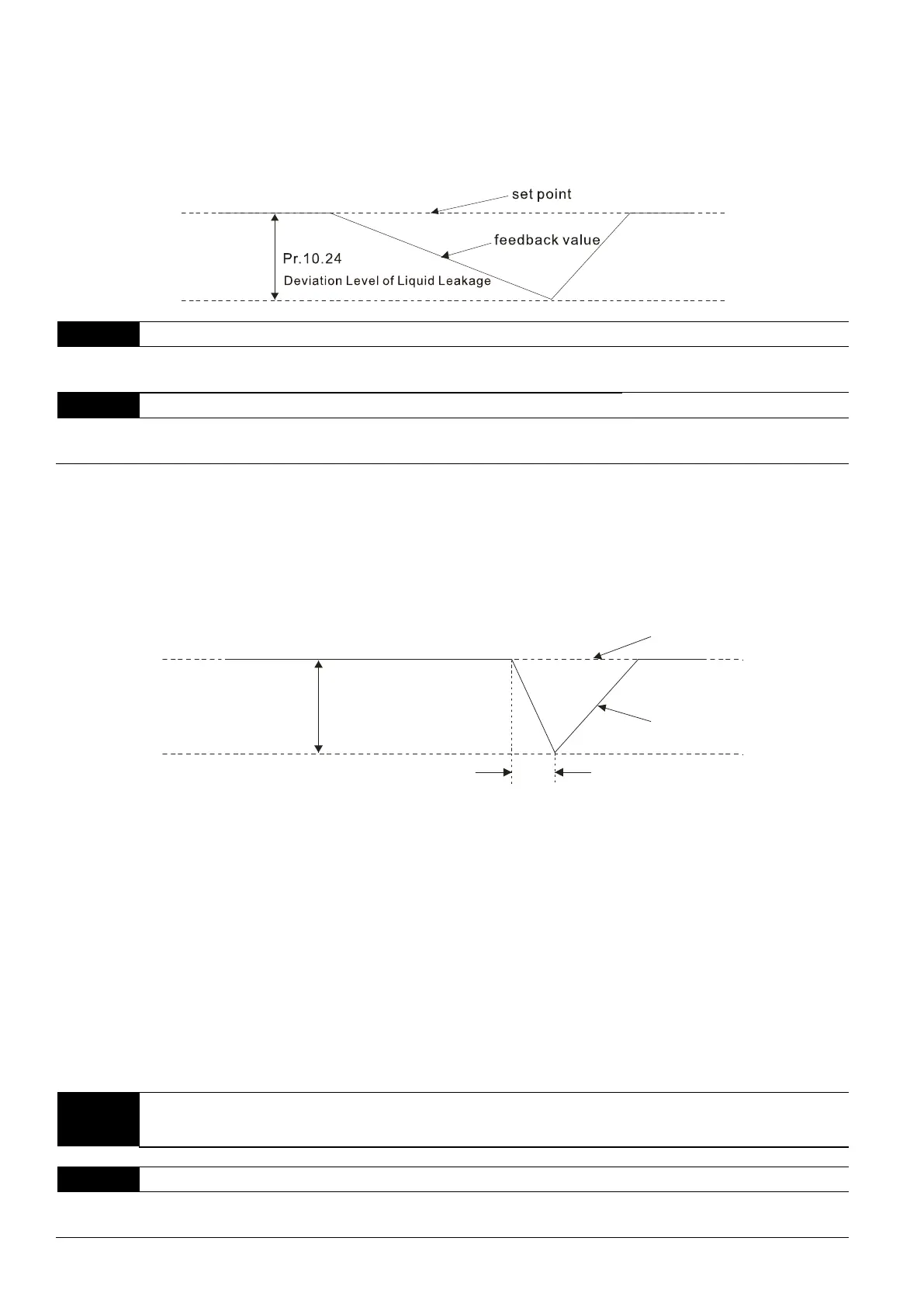

Pr.10.24 is based on the set point set by the PID control. When the drive does not run and is in a constant

pressure status, and if the error is higher than Pr.10.24 due to liquid leakage (minor pressure loss), the AC

motor drive starts to run.

Use this parameter to avoid the drive’s frequent start-up and stop due to liquid leakage (minor pressure

loss).

Liquid Leakage Deviation Level Detection

10.25

Liquid Leakage Change Detection Unit: 1

Settings 0–100%

(0: Disable)

Default: 0

10.26

Time Setting for Liquid Leakage Change Unit: 0.1

Settings 0.1–10.0 sec.

(0: Disable)

Default: 0.5

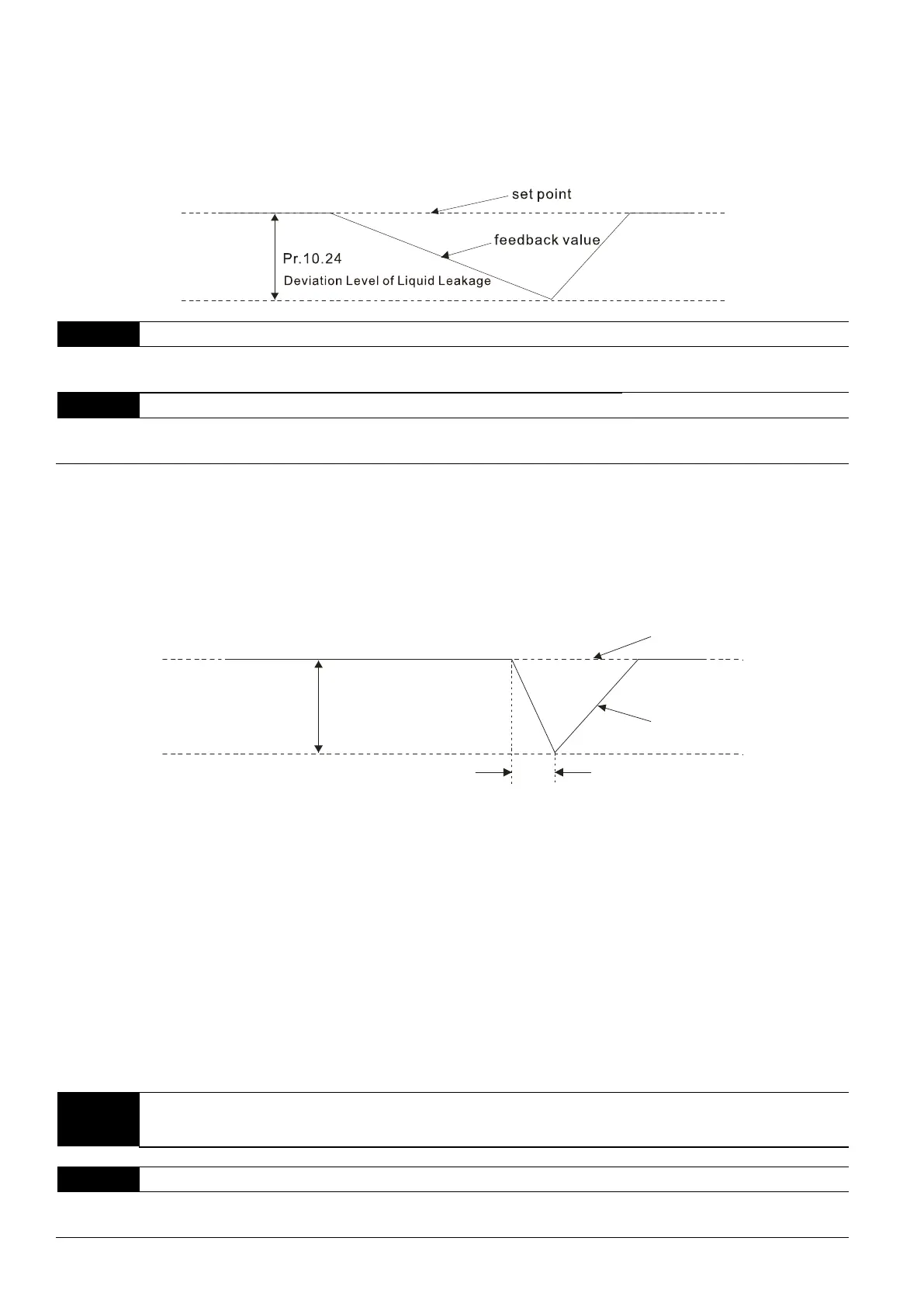

Pr.10.25 and Pr.10.26 define the variation of the feedback value within a time unit in the case of liquid

leakage (minor pressure loss).

Pr.10.25 sets the variation of the feedback value based on the set point set by the PID control; Pr.10.26 is

the setting value within a time unit. If the variation of the feedback value is less than the settings for

Pr.10.25 and Pr.10.26, the liquid leakage occurs. When the drive does not run and is in a constant

pressure status, and if the variation of the feedback value is higher than the settings for Pr.10.25 and

Pr.10.26, the AC motor drive starts to run in order to keep the system stable.

Liquid Leakage / Usage Deviation Level Detection

feedbac k v al ue

10.25

Example:

Assume that the set point of a constant pressure control for a pump is 4 kg, Pr.10.22=5%, Pr.10.23 =15

seconds, Pr.10.24=25%, Pr.10.25=3% and Pr.10.26=0.5 second, then the deviation is 0.2 kg (4 kg X 5% =

0.2 kg). That is, when the feedback value is higher than 3.8 kg and the time exceeds 15 seconds, the AC

motor drive decelerates to stop (this deceleration time is according to the Deceleration Time 2 in Pr.01.12).

When the feedback value is less than 3.8 kg, the AC motor drive starts to run.

Case 1: Assume that when the AC motor drive does not run and is in a constant pressure status, the

variation of the feedback value is less than 0.12 kg (4 kg X 3% = 0.12 kg) within 0.5 second. When the

feedback value continues to decrease to make the deviation of the set point be less than 1 kg (4 kg X 25%

= 1 kg), that is, when the feedback value is less than 3 kg, the AC motor drive starts to run.

Case 2: Assume that when the AC motor drive does not run and is in a constant pressure status, the

variation of the feedback value is higher than 0.12 kg (4 kg X 3% = 0.12 kg) within 0.5 second; that is,

when the feedback value is less than 3.88 kg [4-(4 kg X 3%) = 3.88 kg] within 0.5 second, the AC motor

drive starts to run.

10.27

|

10.33

Reserved

10.35

Multi-pump Control Mode

Settings 0–2

0: Disable

Default: 0

Loading...

Loading...