Chapter 4 WiringMS300

23

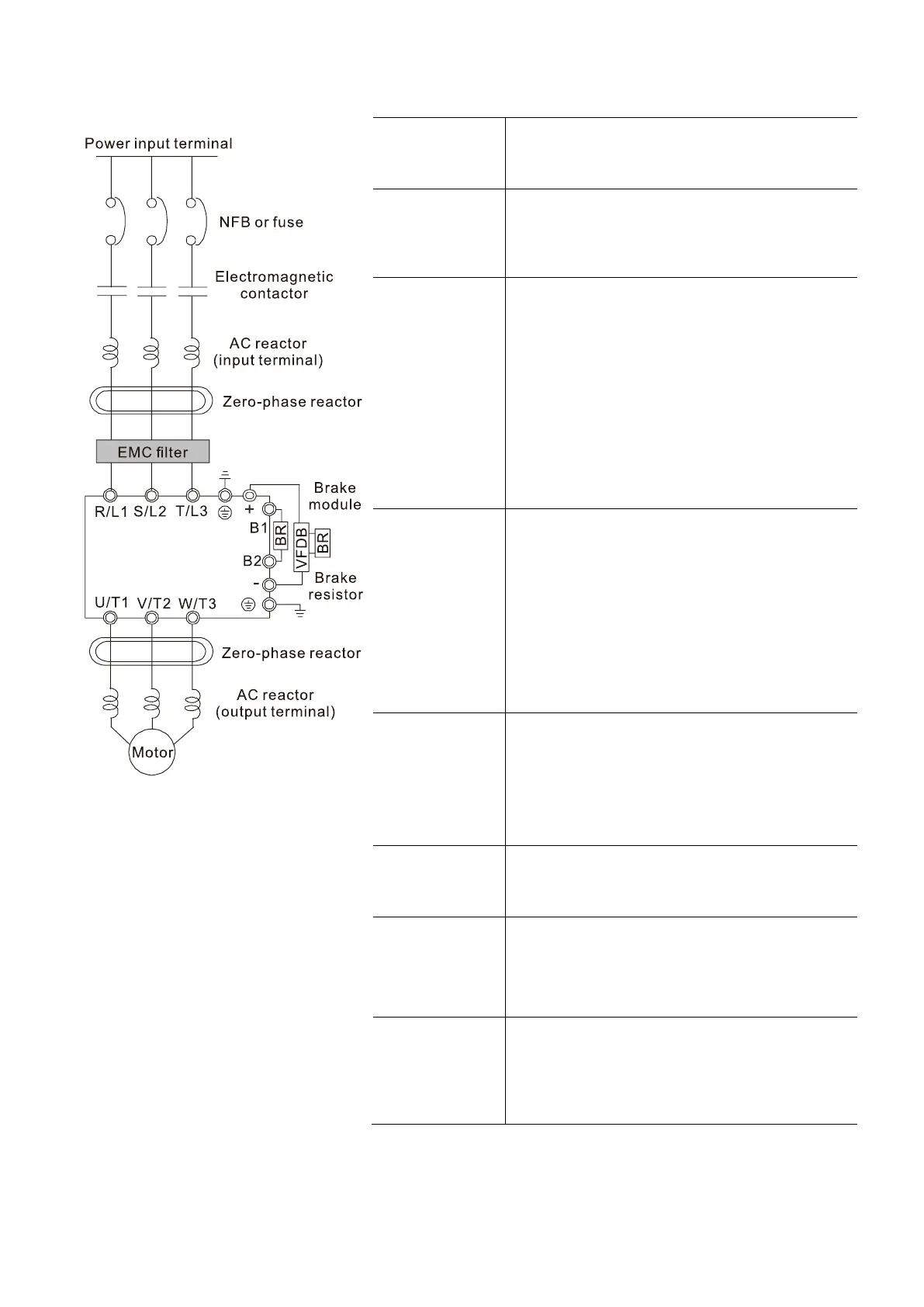

4-1 System Wiring Diagram

Supply power according to the rated power

specifications indicated in the manual (refer to

Chapter 9 Specification).

There may be a large inrush current during

power on. Refer to Section 7-2 NFB to select a

suitable NFB or Section 7-3 Fuse Specification

Chart.

Electromagnetic

contactor

Switching the power ON/OFF on the primary

side of the electromagnetic contactor can turn

the drive ON/OFF, but frequent switching can

cause machine failure. Do not switch ON/OFF

more than once an hour.

Do not use the electromagnetic contactor as the

power switch for the drive; doing so shortens the

life of the drive.

Refer to Section 7-2 Magnetic Contactor / Air

Circuit Breaker to select the electromagnetic

contactor that meets your requirement.

AC reactor

(input terminal)

When the main power supply capacity is greater

than 500 kVA, or when it switches into the phase

capacitor, the instantaneous peak voltage and

current generated may destroy the internal

circuit of the drive.

It is recommended that you install an input side

AC reactor in the drive. This also improves the

power factor and reduces power harmonics. The

wiring distance should be within 10 m. Refer to

Section 7-4 AC/DC Reactor for details.

Used to reduce radiated interference, especially

in environments with audio devices, and reduce

input and output side interference.

The effective range is AM band to 10 MHz.

Refer to Section 7-5 Zero Phase Reactors for

details.

Can be used to reduce electromagnetic

interference. Refer to Section 7-6 EMC Filter for

details.

Brake module

&

Brake resistor

(BR)

Used to shorten the deceleration time of the

motor. Refer to Section 7-1 Brake Resistors and

Brake Units Used in AC Motor Drives for details.

AC reactor

(output terminal)

The motor cable length affects the size of the

reflected wave on the motor end. It is

recommended that you install an AC output

reactor when the motor wiring length exceeds

the value listed in Section 7-4.

Loading...

Loading...