Chapter 16 PLC Function ApplicationsMS300

765

16-9 Count Function Using Pulse Input

16-9-1 High-speed count function

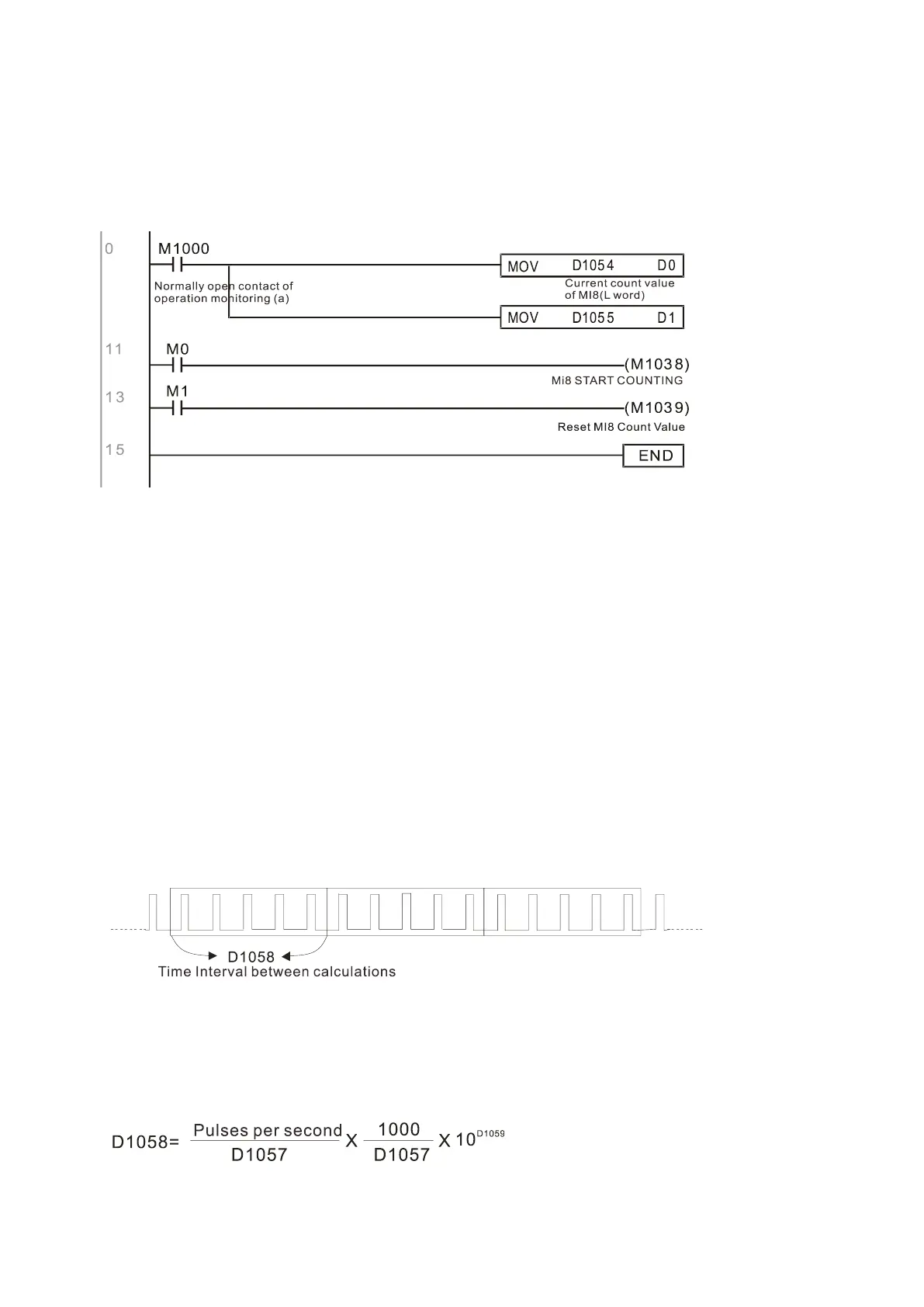

The MS300's MI7 supports one-way pulse counting with a maximum speed of 33 k. The starting

method is very simple, and only requires setting M1038 to begin counting. The 32-bit count value is

stored in D1054 and D1055 in non-numerical form. M1039 resets the count value to 0.

NOTE: When the PLC program defines MI7 for use as a high-speed counter, that is, when M1038 or

M1039 is written in PLC procedures, other functions of MI7 are disabled.

16-9-2 Frequency calculation function

Apart from high-speed counting, the MS300's MI7 can also convert a received pulse to a frequency.

The following figure shows that there is no conflict between frequency conversion and count

calculations, which the MS300 can perform simultaneously.

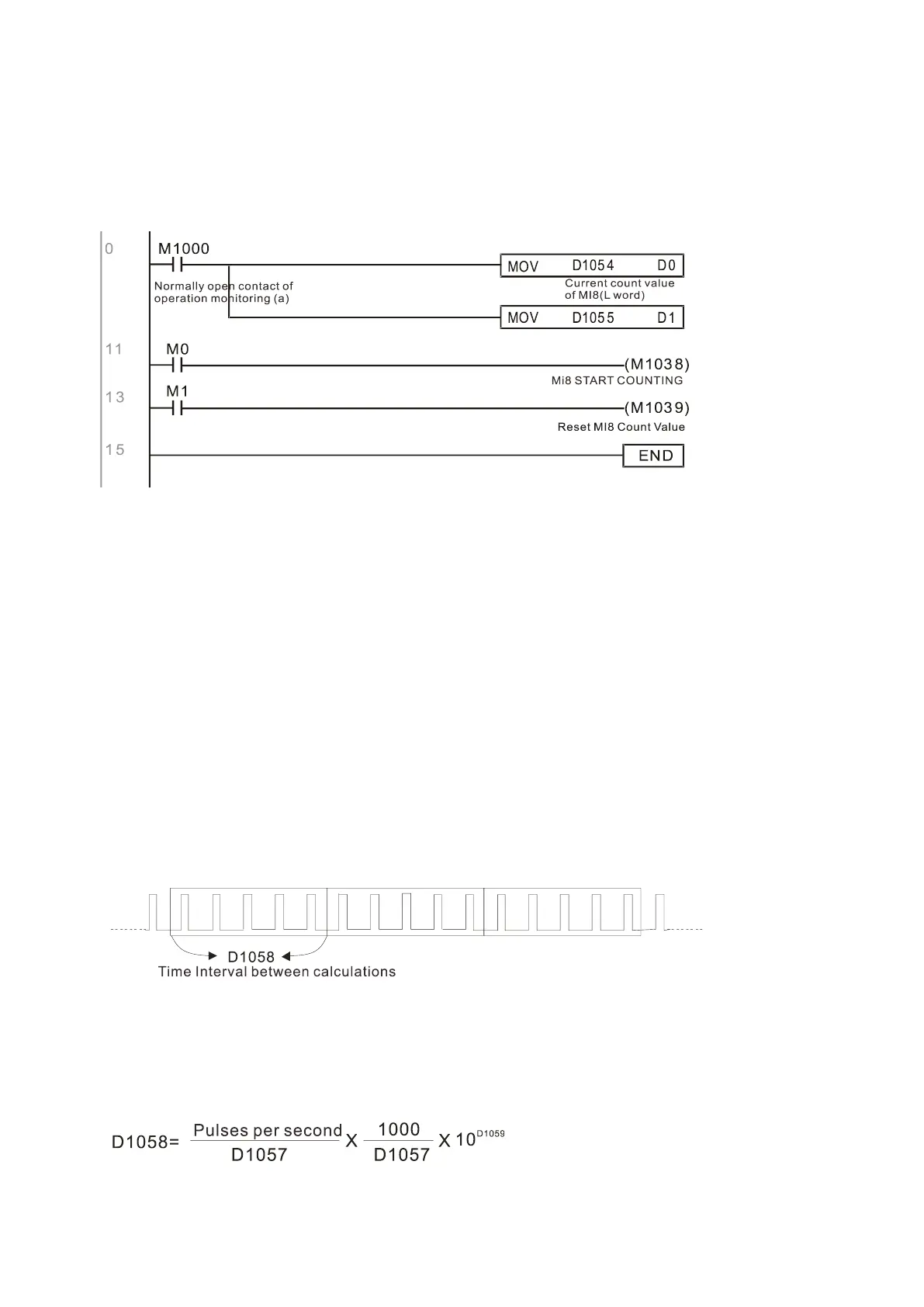

PLC speed calculation formula

D1057 Speed

D1058 Interval between calculations

D1059 Decimal places

Assume that there are five input pulses each second, (see figure below) we set D1058 = 1000 ms =

1.0 second as the calculation interval. This enables five pulses to be sent to the drive each second.

Assume that each five pulses correspond to 1 Hz, we set D1057 = 5.

Setting D1059 = 2 displays numbers to two decimal places, which is also 1.00 Hz. The numerical

value displayed at D1056 is 100. For simplicity, the D1059 conversion formula can be expressed in

the following formula:

Loading...

Loading...