10

DCD-710AE

Note Handling and Replacement of the Laser pick-up

1. Protection of the LD

Short a part of the LD circuit by soldering. After connection to a circuit, remove the short solder.

2. Precautions when handling the laser CD mechanism

• Handle the laser pick-up so that it is not exposed to dust.

• Do not leave the laser pick-up bare. Be sure to cover it.

• If dust adheres on lens of the pick-up, blow it off with a blower brush.

• Do not shock the laser pick-up.

• Do not watch the light of the laser pick-up.

3. Cautions on assembling and adjustment

• Be sure that to the bench, jig, head of soldering iron (with ceramic) and measuring instruments are well grounded.

• Workers who handle the laser pick-up must be grounded.

• The finished mechanism (prior to anchoring in the set) should be protected against static electricity and dust. The mecha-

nism must be stored that damaging outside forces are not received.

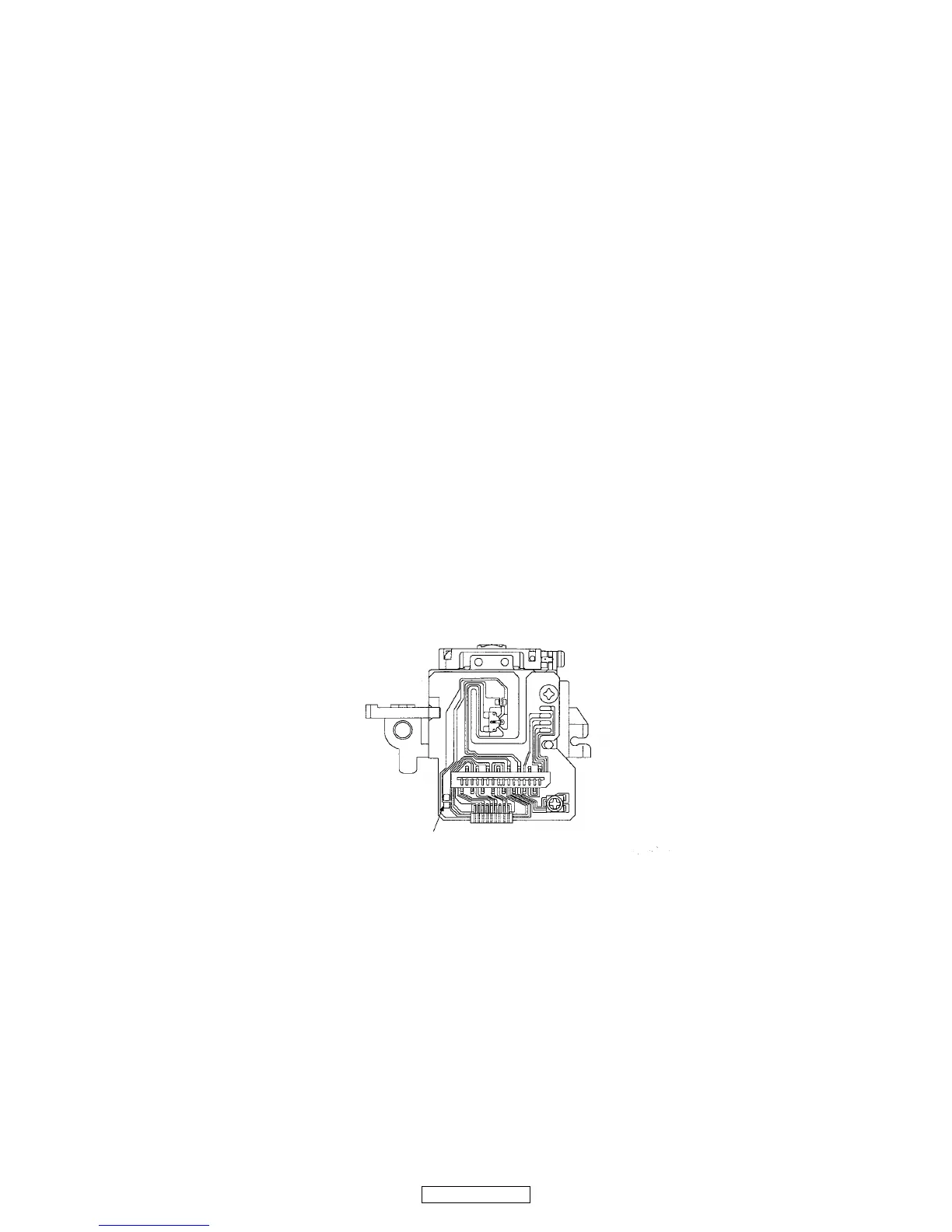

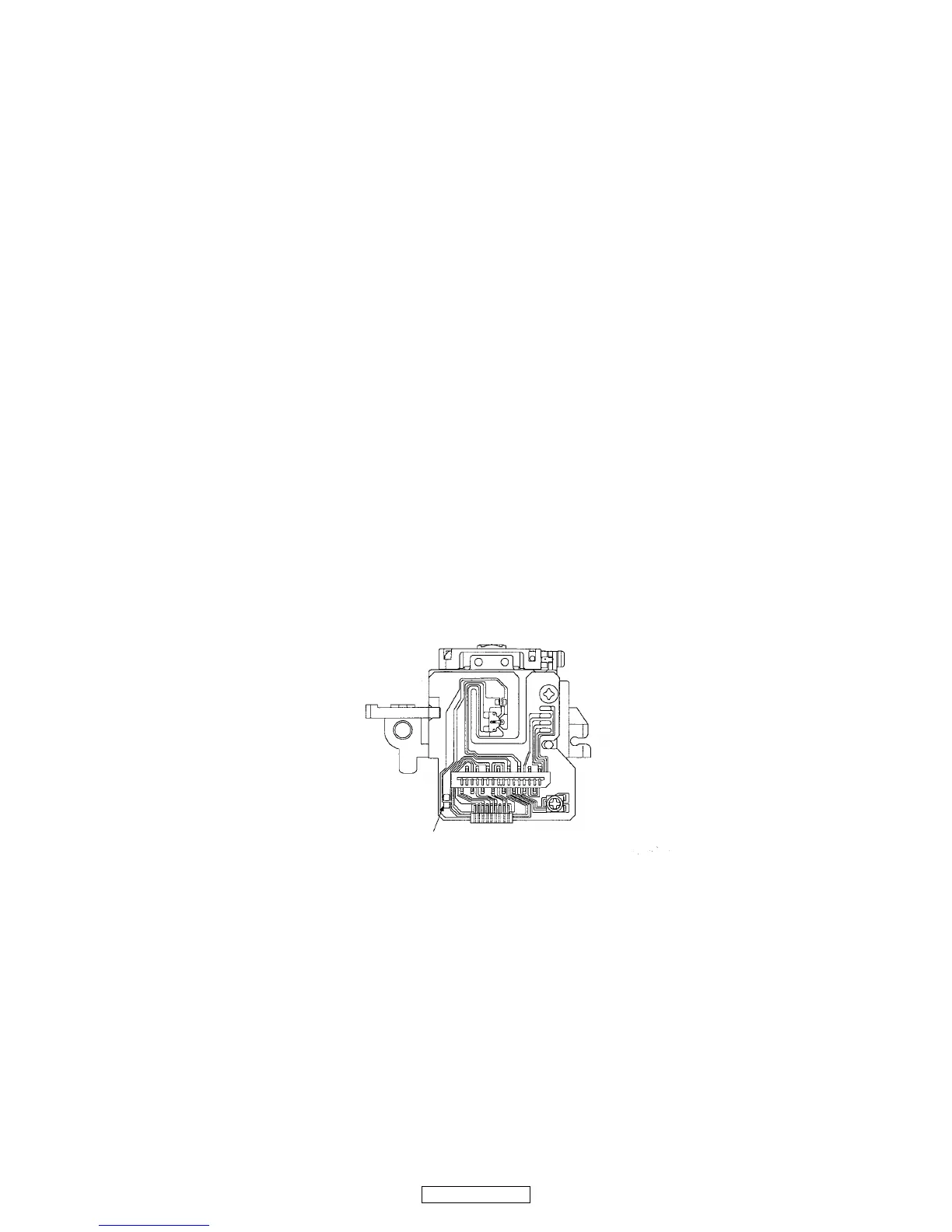

• When carrying the finished mechanism, hold it by the

chassis body

• For proper operation, storage and operating environment should not contain corrosive gases. For example H

2S, SO2, NO2,

CI2 etc. In addition storage environment should not have materials that emit corrosive gases especially from silicic, cyanic,

formalin and phenol group. I the mechanism or the set, existence of corrosive gases may cause no rotation in motor.

4. Determining whether the laser pick-up is defective

•

Measure the waveform at RFO-VC on "MCU P.W.B. Unit ".

( For measuring points and waveforms, see pages 21.)

• The laser pick-up is OK if the amplitude level of the measured RFO waveform is between 0.4 and 1.1 Vp-p, defective oth-

erwise.

Loading...

Loading...