ENGLISH

7

volume of chips ejected during planing. The vacuum hose

may clog, stopping the flow ofchips.

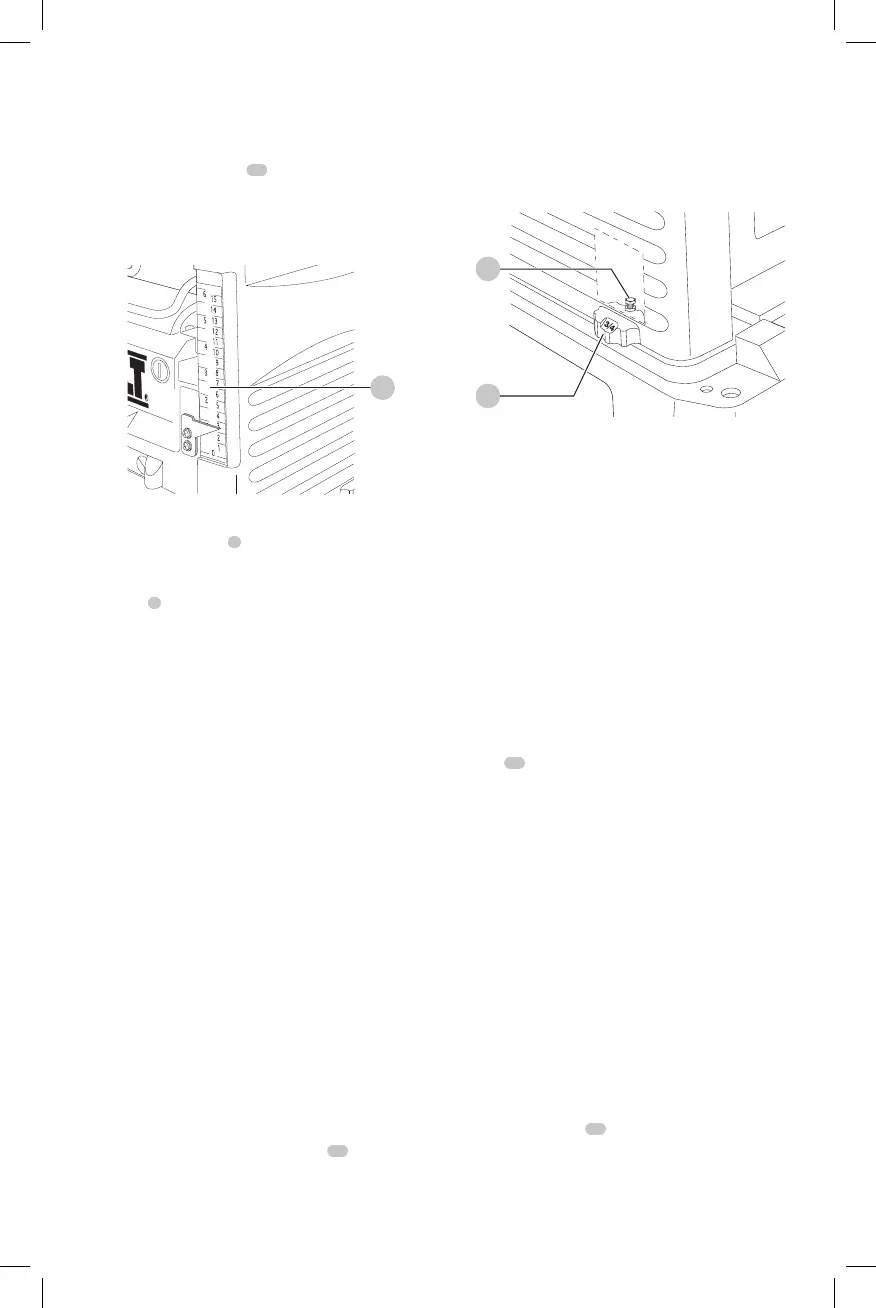

Depth Adjustment (Fig. I)

The depth adjustment scale

10

indicates the finished

thickness of your workpiece. One rotation of the depth

adjustment crank is equal to 1/16" (1.6mm); half a rotation

is equal to 1/32" (0.8mm),etc.

Fig. I

10

To Set the Finished Thickness (Fig. D)

1. Raise head lock lever

9

to unlock the cutterhead. This

allows the cutterhead to beadjusted.

2. Adjust the thickness. Turn the depth adjustment

handle

6

clockwise to lower the cutterhead. Turn the

handle counterclockwise to raise the cutterhead. One

full rotation of the handle moves the cutterhead 1/16"

(1.6mm).

3. Depress the head lock lever to re-lock beforeplaning.

NOTE: Do not attempt to adjust the carriage height while

the carriage lock is engaged. You may damage themachine.

Fine Adjustments

The depth adjustment handle allows for fine adjustments,

from 1/64" (0.4mm) to 1/16" (1.6mm).

Fine adjustments are ideal for “shaving” small amounts

from your material. For example, if your planed workpiece

measures 3-1/16" (77.8mm) thick, but should be 3"

(76.2mm) thick, adjust your planer to remove the excess

1/16" (1.6mm) as follows:

1. Plane and measure your workpiece. In this example, the

starting thickness is 3-1/16" (77.8mm).

2. Turn the circular label on the depth adjustment handle

until the “0” mark aligns with the arrow on the top

of the tool. Do not make any other adjustments to

theplaner.

3. Turn the depth adjustment handle clockwise until the

1/16" (1.6mm) mark aligns with thearrow.

4. Plane your workpiece. The final thickness should be 3"

(76.2mm).

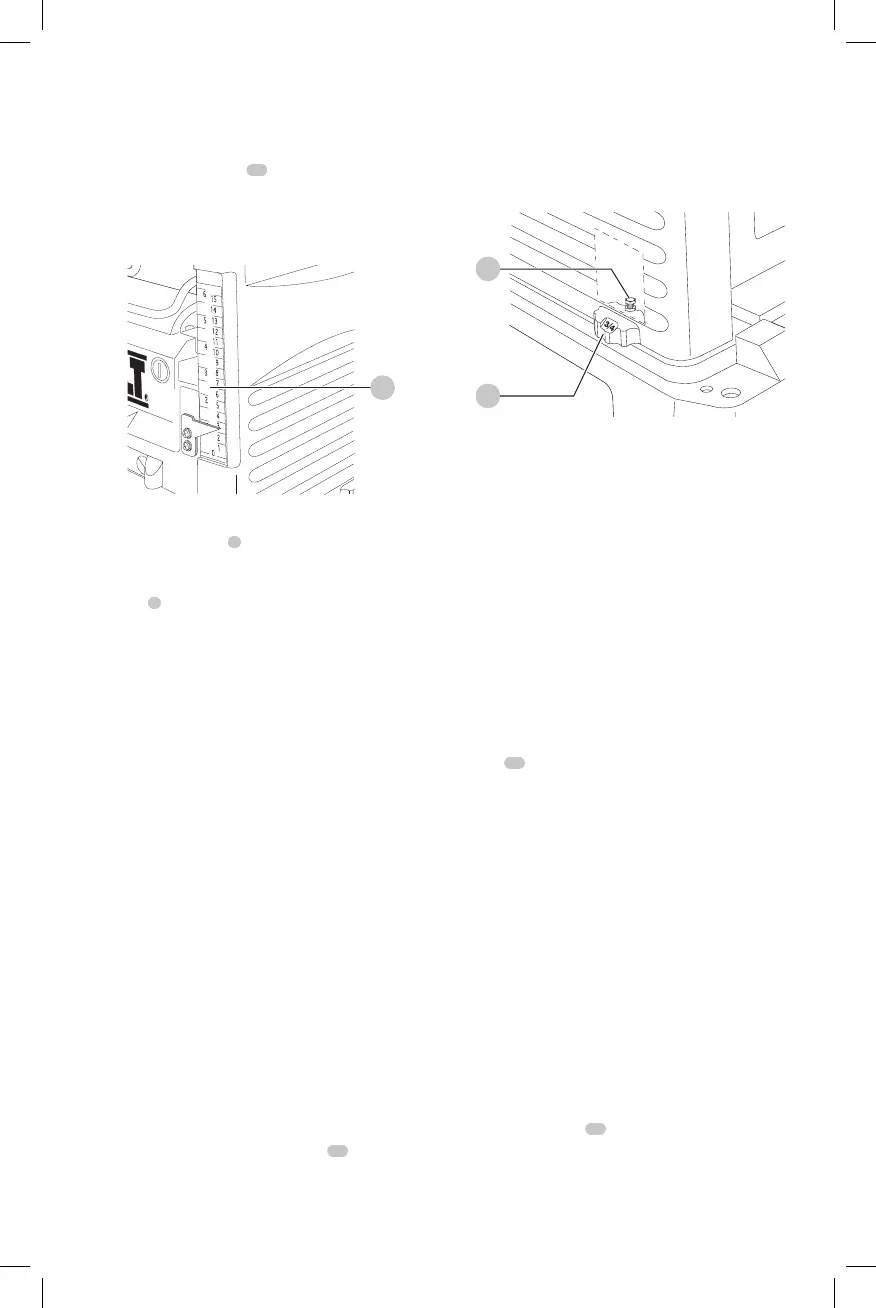

Turret Stop (Fig. D, J)

Your planer is equipped with a turret stop

13

, shown in

FigureJ, for repetitive planing of pre-set depths. Stops are

set at 0", 1/4" (6.4 mm), 1/2"12.7 mm) and 3/4" (19.0 mm).

Use the 0" setting when planing between 1/8" (3.2 mm) and

1/4" (6.4mm).

To Set a Planing Depth

1. Be sure the carriage is set above 1-1/4" (31.8 mm)

before trying to set the turretstop.

2. Turn the turret stop until the desired measurement

shows (Fig.J).

Fig. J

14

13

3. Unlock the head lock lever (Fig.D). Turn the depth

adjustment crank, lowering the carriage by the desired

increments, until it contacts the turretstop.

NOTE: DO NOT USE FORCE TO CRANK THE CARRIAGE

BELOW THE LEVEL THAT THE TURRET STOP INDICATES.

PERMANENT DAMAGE TO THE HEIGHT ADJUST MENT

SYSTEM ON YOUR PLANER WILLRESULT.

NOTE: The 3/4" (19.0 mm) turret stop can be adjusted for

other planing thicknesses. Adjusting the 3/4" (19.0 mm)

turret stop does not affect the other turret stopsettings.

To Adjust the 3/4" (19 mm) Stop for

Other Thicknesses

1. Unlock the head lock lever (Fig.D) and turn the

adjustment handle counterclockwise to raise

thecutterhead

2. From the back of the tool, locate the turret adjustment

bolt

14

shown in FigureJ. This bolt is set for a 3/4"

(19.0mm) depth of cut at the factory. Adjust the bolt up

or down to reach the desired planingdepth.

3. Turn the depth adjustment crank, lowering the

carriage by the desired increments, until it contacts the

turretstop.

Calibrating the Depth Adjustment Scale

The depth adjustment scale on your planer is set at the

factory. However, with extended use, the depth adjustment

scale could show an incorrectmeasurement.

To Check the Depth Adjustment Scale

(Fig. K)

1. Plane a piece of wood, noting the measurement on the

depth adjustmentscale.

2. Measure the finished thickness of theworkpiece.

3. If the thickness of the workpiece does not match the

reading on the depth adjustment scale, loosen the two

cross head screws

18

shown in FigureK.

Loading...

Loading...