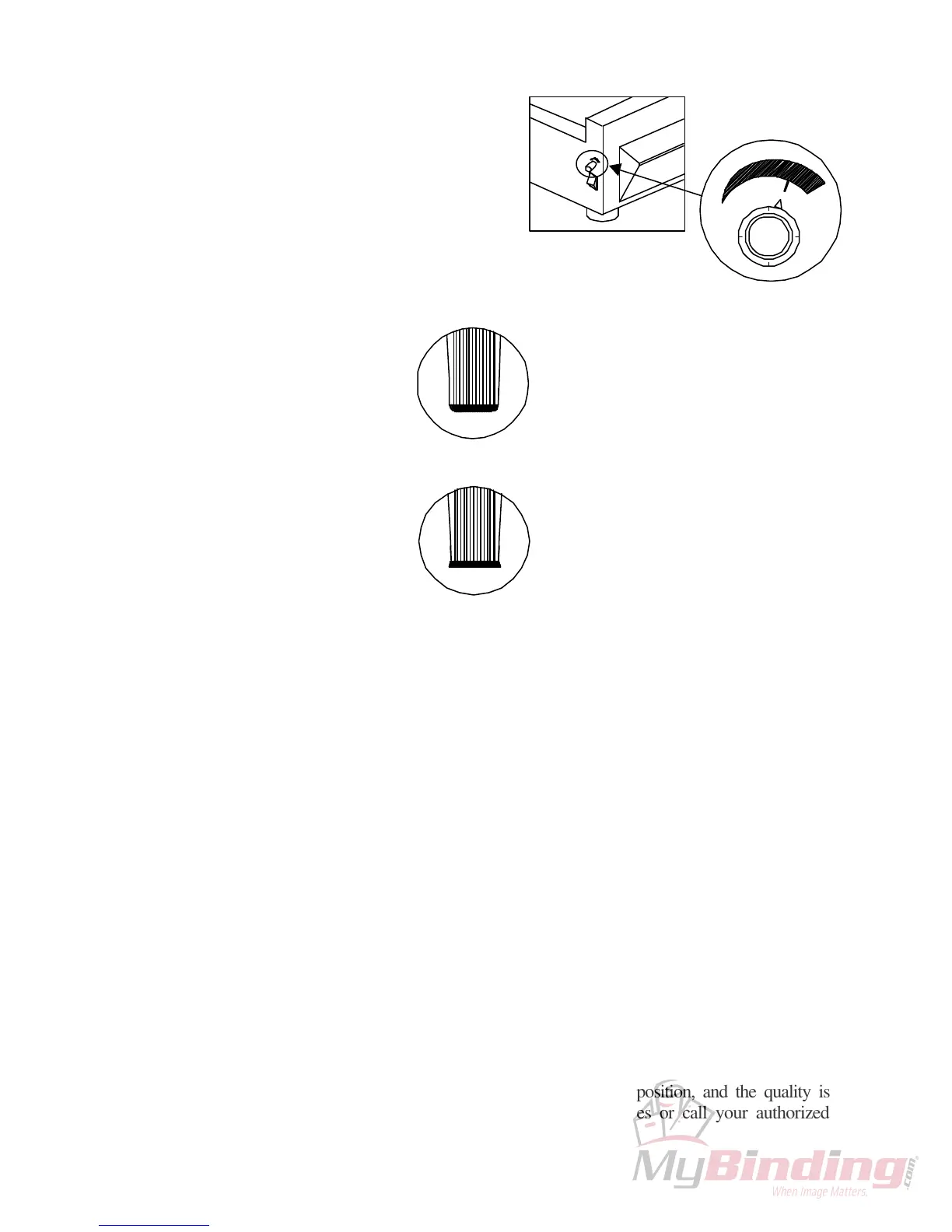

6-3 NIPPING PRESSURE CONTROL :

The nipping pressure control knob is

located on the left-side of the machine

(next to the power switch). It allows

you to adjust the nipping pressure

based on the thickness of the books

and the quality of the book spine.

Normally the thinner the books, the

more the nipping pressure. The factory

setting is set to the mark on the scale.

• Turn the knob clockwise to increase the nipping pressure when

round spine occurs or making thinner books.

• Turn the knob counter clockwise to decrease the nipping pressure when

nail head spine occurs or making thicker books.

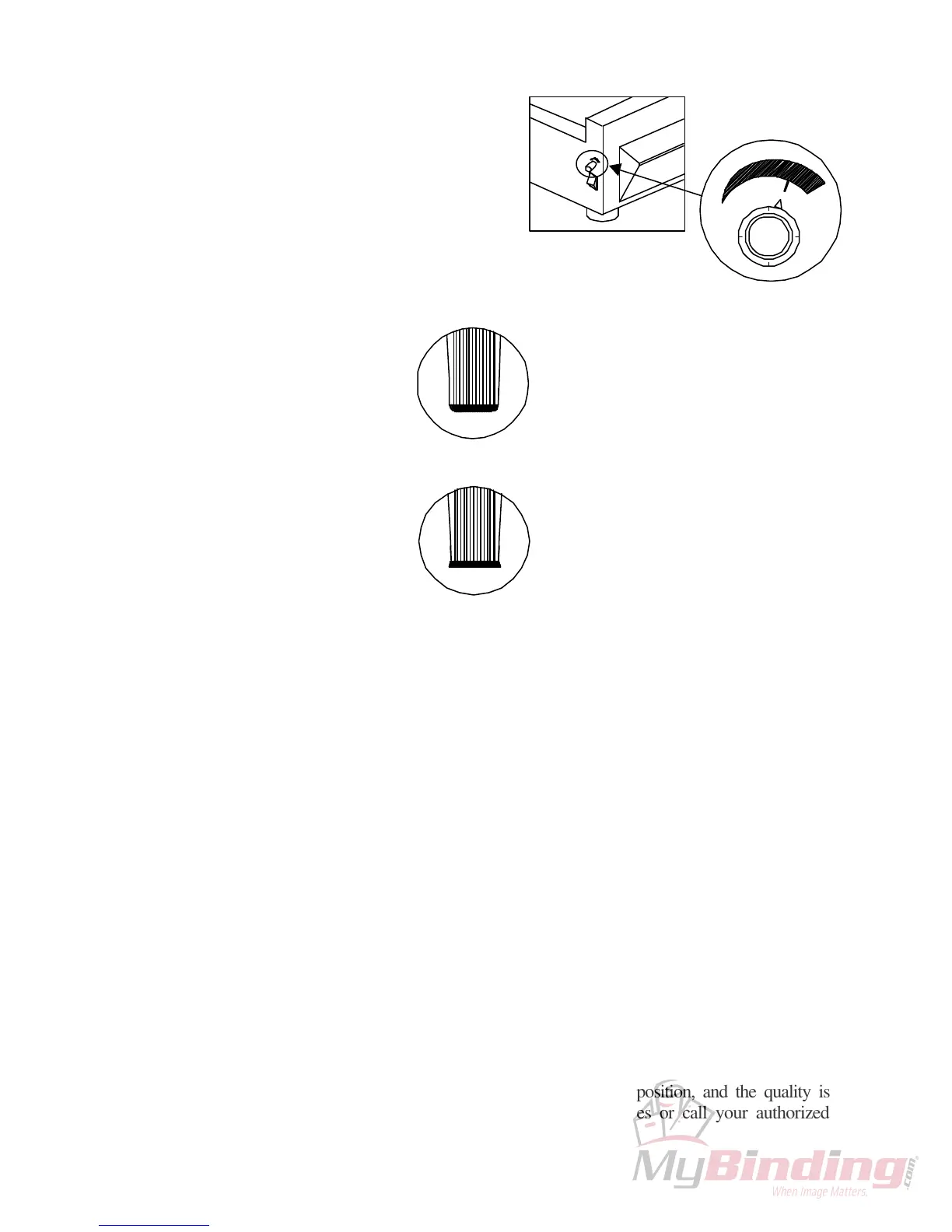

6-4 REPLENISHING THE GLUE TANK :

CAUTION: Great care must be taken when handling hot molten glue.

Be sure not to place an excessive amount of glue in the tank at one time. Keep it at

such a level that the glue will not go over the redline in the tank while the application

drum is rotating. This will prevent glue from spilling out of the tank.

Glue Replacement

1. Warm up the DB-250 as described in the STARTUP section on page 5.

2. Make sure the draining tray is warped by Aluminum foil and positioned

underneath the glue tank so that the tank drains into it.

3. Use the 6 mm Allen wrench to loosen (Counter Clockwise) the glue drain Allen

screw, which is located on top of the glue tank.

Do not attempt to remove the draining tray until the glue cools down.

4. Close (Clockwise) the glue drain Allen screw when the glue stops flowing.

5. Add new glue to the glue tank Be sure to keep the glue level not going over the red

line.

6. Remove the glue drain tray and discard the cold drained glue.

Note that it’s not necessary to drain the glue frequently if the machine is used

constantly under normal working conditions. However, in case the glue has been left

unused for a long period of time with the unit in the “ON” position, and the quality is

found to be unacceptable, use the glue replacement procedures or call your authorized

dealer.

Loading...

Loading...