DUPLOMATIC E.M.DDC4-400V/RK RELEASE 1.9 07-09

EM DDC4-400-RK-0709gb.doc 13

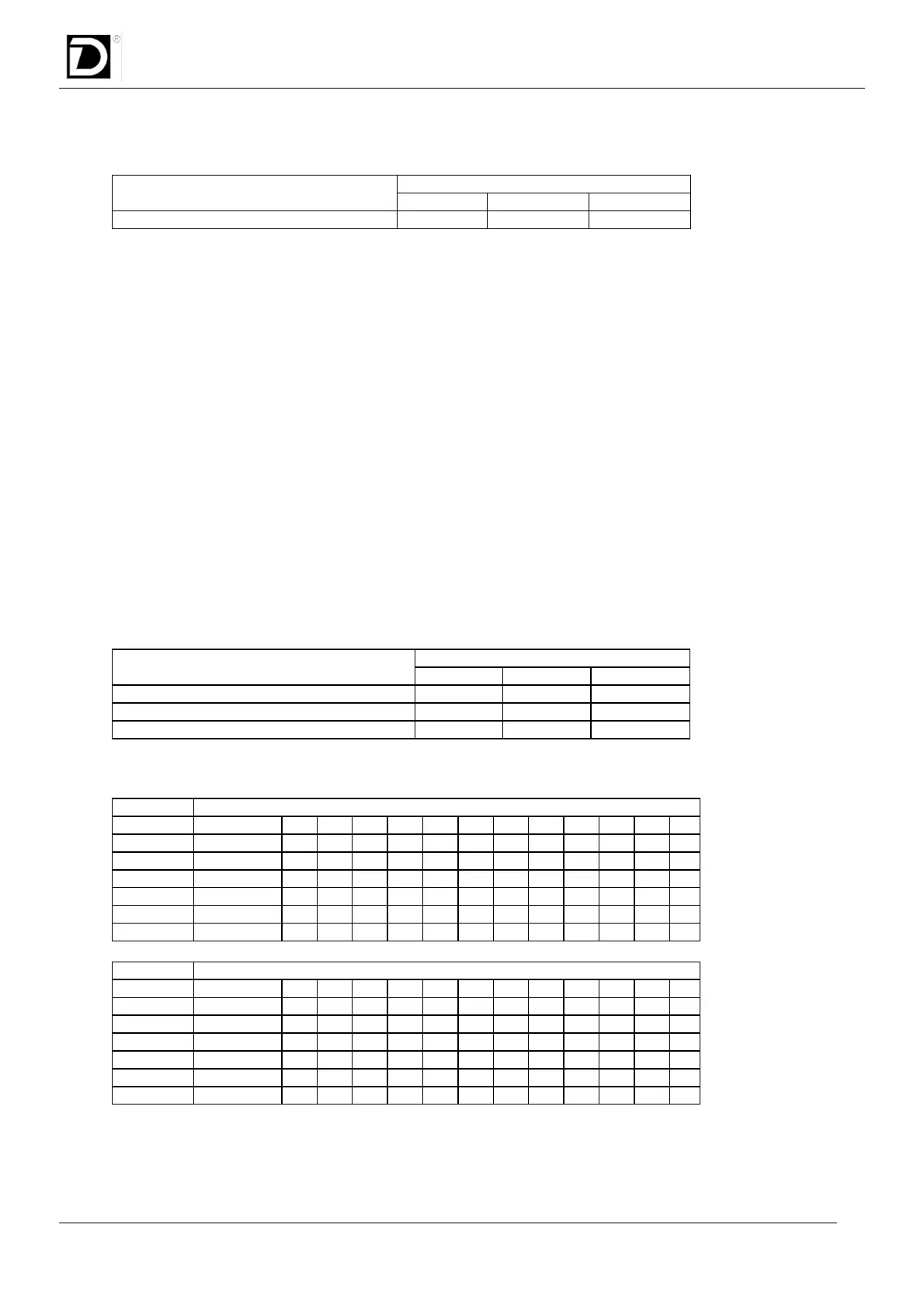

OPERATING FUNCTION N°0: EMERGENCY / RESET

INPUTS OPERATING FUNCTION N°0

MODE01 MODE02 MODE03

Emergency/reset

0 0 0

This operating function has two purposes:

1) Stop all turret movement (EMERGENCY).

2) Acknowledge all alarms, if they are present (RESET).

It must stay on for more than 30 ms to be read by the control unit. It isn’t necessary to carry out a RESET to go

into or out operating function. Meanwhile, the transition from one operating function to the other could generate

a transitory condition that can be detected as an emergency request.

The INDEX signal goes low after a RESET.

The alarm output will be cleared changing from operating function N°0 to another operating function (e.g.

Automatic).

In any case, after changing from mode 0 to any other mode, it is necessary to wait 800 ms before any

variation of PSTART signal.

OPERATING FUNCTION N°1,2,3: AUTOMATIC

These operating functions are normally used to drive the turret.

Just set the code of the position required, give the start signal and the turret will automatically reach the

position.

1. Clear all alarms (if present);

2. Set an automatic function:

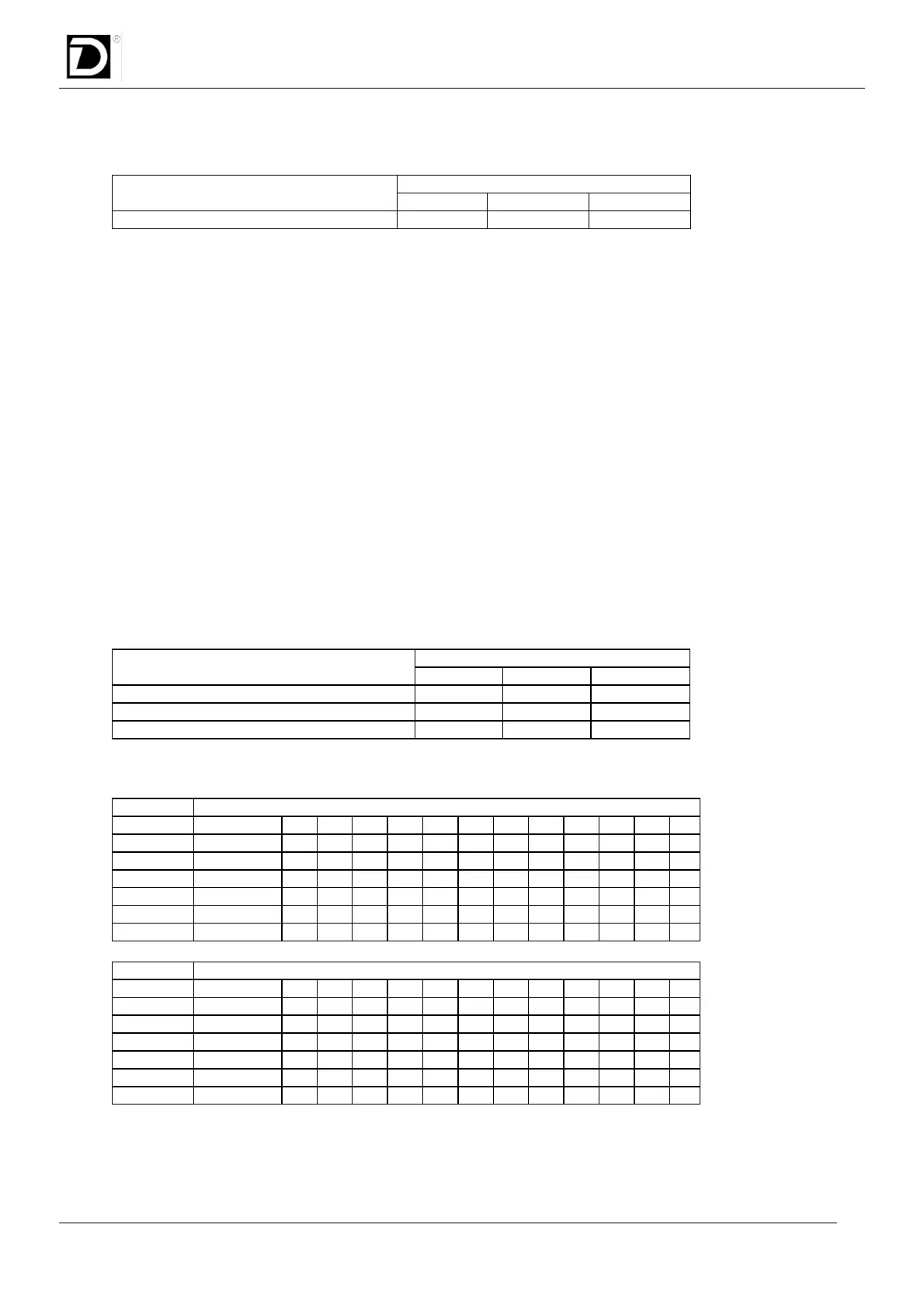

INPUTS OPERATING FUNCTION N°1,2,3

MODE01 MODE02 MODE03

Automatic with shortest path search

1 0 0

Automatic CW

0 1 0

Automatic CCW

1 1 0

3. Set the position code: (use PBIT16 only for turrets with 16 tools or more).

POSITION

CODE Zero Cycle 1 2 3 4 5 6 7 8 9 10 11 12

PBIT01

0 1 0 1 0 1 0 1 0 1 0 1 0

PBIT02

0 0 1 1 0 0 1 1 0 0 1 1 0

PBIT04

0 0 0 0 1 1 1 1 0 0 0 0 1

PBIT08

0 0 0 0 0 0 0 0 1 1 1 1 1

(PBIT16)

0 0 0 0 0 0 0 0 0 0 0 0 0

PARITY

0 1 1 0 1 0 0 1 1 0 0 1 0

POSITION

CODE 13 14 15 16 17 18 19 20 21 22 23 24

PBIT01

1 0 1 0 1 0 1 0 1 0 1 0

PBIT02

0 1 1 0 0 1 1 0 0 1 1 0

PBIT04

1 1 1 0 0 0 0 1 1 1 1 0

PBIT08

1 1 1 0 0 0 0 0 0 0 0 1

(PBIT16)

0 0 0 1 1 1 1 1 1 1 1 1

PARITY

1 1 0 1 0 0 1 0 1 1 0 0

4. Set PSTART for give the confirmation of the movement within 5 s.

(It must stay ON for more than 30 ms).

Loading...

Loading...