IF 1767 • 09/15 Copyright

©

2015, Eaton’s Crouse-Hinds Division Page 6

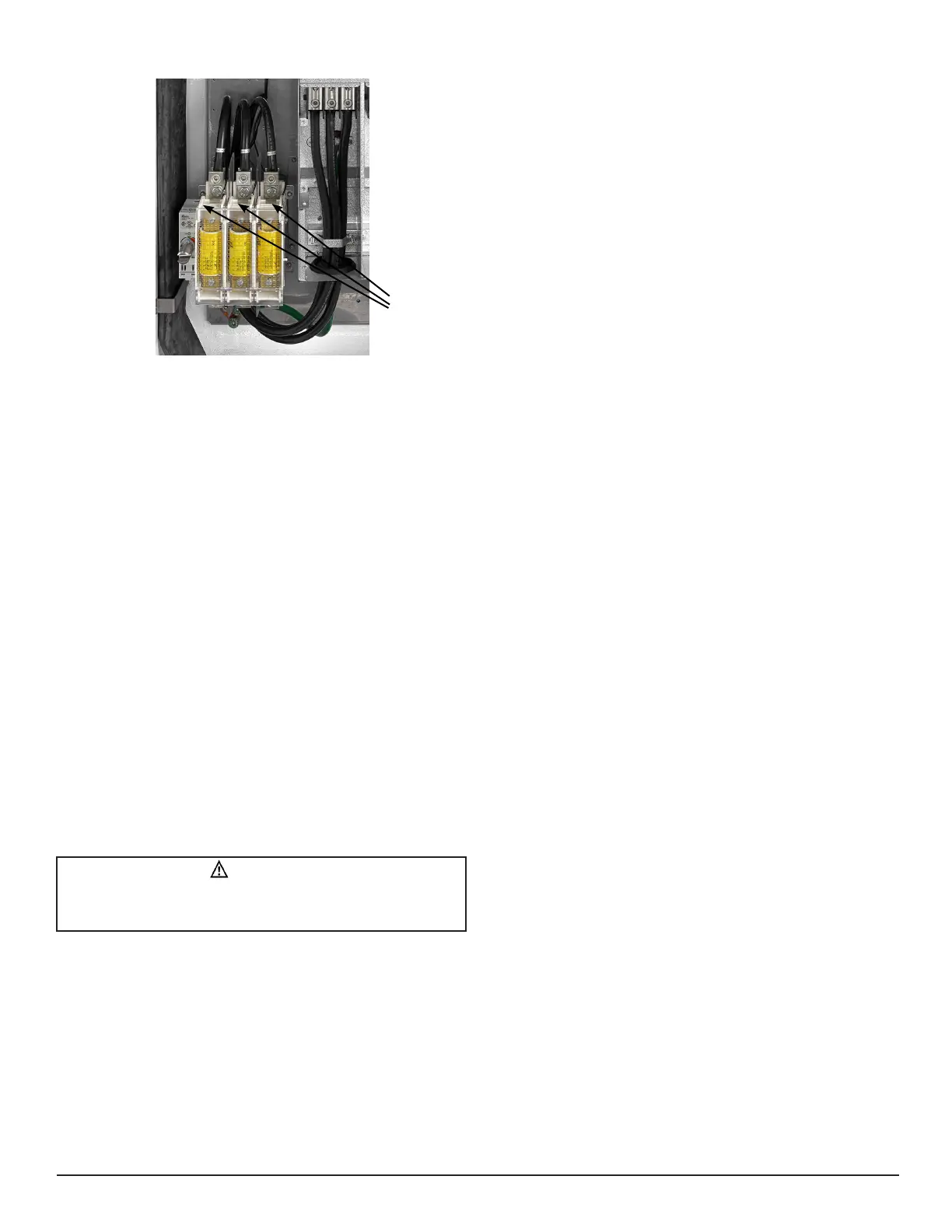

3.2 LINE FEED

This equipment is designed for line connection directly to the integral

disconnect switch. Factory wiring transmits power to the variable

frequency drive.

1. Size line wiring according to drive manufacturer’s specifications.

2. Attach line conductors with phase A on the left, B center and C to

the right (see torque table in Section 5.3).

3.3 LOAD FEED AND SHIELD GROUNDING TO

DRIVE

This equipment is designed for load connection directly from the variable

frequency drive, although, in the case of an oversized VFD for the given

motor, use the VFD and motor manufacturer’s recommendations for

proper motor overload protection. In certain cases, it is required to

include additional motor overload protection between the VFD and the

motor for proper motor overload protection. Always be sure to shield

load wiring from line and control wiring to reduce noise. Refer to the

drive manufacturer’s manual for further details.

1. Attach load conductors with phase A to U, B to V, and C to W (see

torque table in Section 5.3).

2. Attach motor cable shielding to VFD ground (see recommendations

by drive manufacturer).

3. Refer to the drive manufacturer’s manual for further information

regarding drive installation.

3.4 CONTROL WIRE ROUTING

To avoid the transmission of noise to/from the blower, control system

and/or the variable frequency drive load conductors, be sure to bundle all

field control wiring and shield as necessary.

Disconnect

Terminals

CAUTION

Failure to add additional motor overload protection between the VFD

and motor when required can cause motor failure and equipment

damage.

Loading...

Loading...