COMMISSIONING

36/64

EN

5.3 Factory pre-setting

Burner Nozzle Pump*

Type gph spray type bar

FB 2 K 18 LN 0,40 80° SF Fluidics 9,3

FB 2 K 20 LN 0,50 80° ES Danfoss 9,8

FB 2 K 26 LN 0,65 80° ES Danfoss 9,3

FB 2 K 35 LN 0,85 60° ES Danfoss 8,6

Reference conditions

– Conventional Flue system: diameter 80 mm / length 1.5 m

– Ambient temperature: 20°C +/-5

– CO2 = 12.5% ± 0,2.

(*) The pump pressure is referred to a stability period of 5 min.

Note.

All the burners are factory tested and adjusted. The air ap and combustion head are set to

have the CO2 % within the above limit.

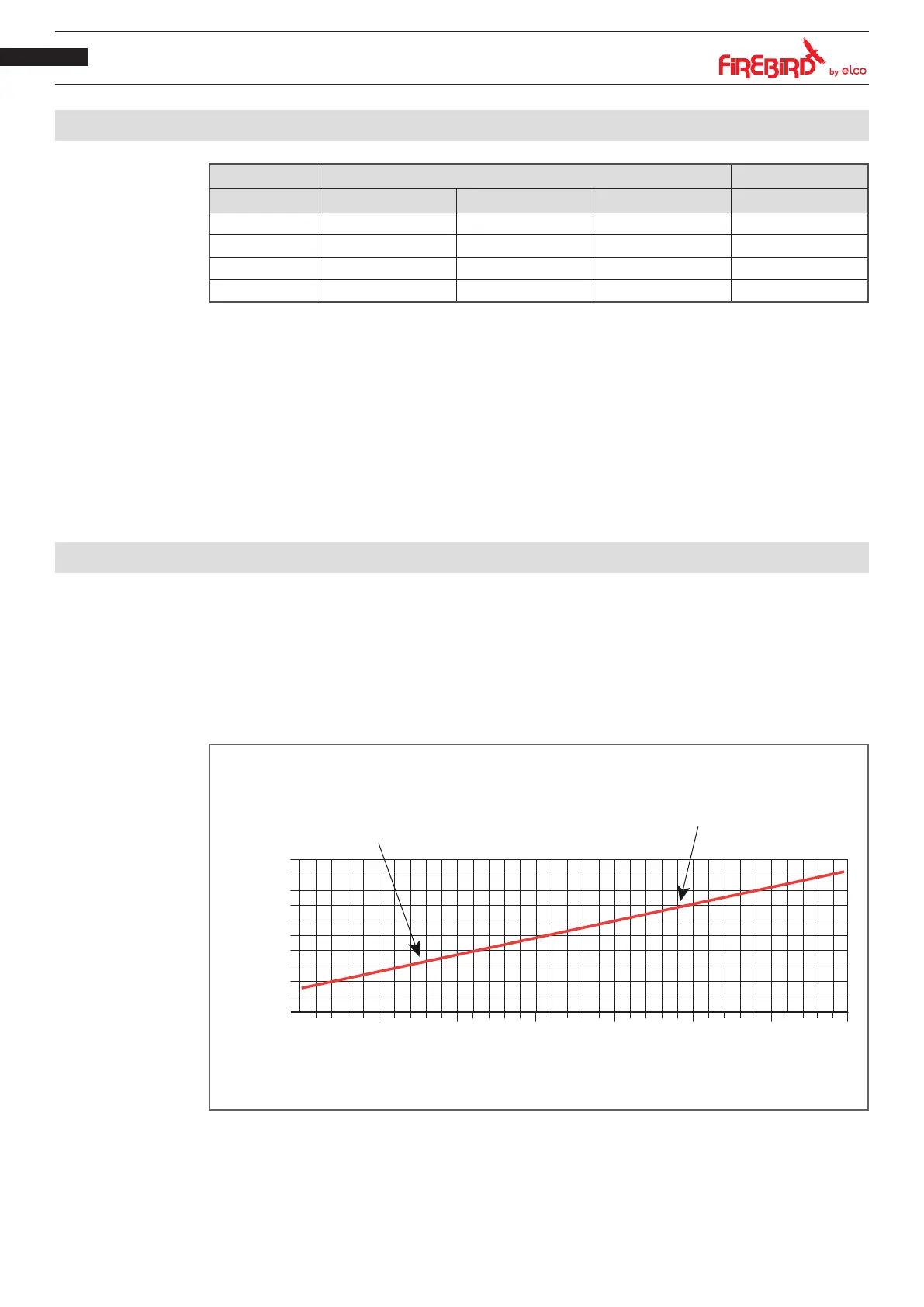

5.4 Combustion adjustment

The burners leave the factory set according to the paragraph “5.3 Factory pre-setting”.

The installation of the burner on the boiler, the commissioning and servicing must be carried out

following the boiler technical manual, including the check of the CO2 and CO level in the ue

gases, their temperatures and the average temperature of the water in the boiler.

In case of outside temperature conditions inuencing the combustion it is recommended to adjust

the CO2 according to the diagram below.

00 5 10 15

Outside air temperature (°C)

20 25

11,00

11,50

12,00

12,50

13,00

CO

2

13,50

30

In the cold of winter aim for

lower CO

2 %. In warmer

times of the year set the

CO

2 higher.

1% rise in CO

2 as the

ambient temperature rises

by 20°C.

Fig. 32

Loading...

Loading...