20

Installation

Hydraulics Circulation pumps

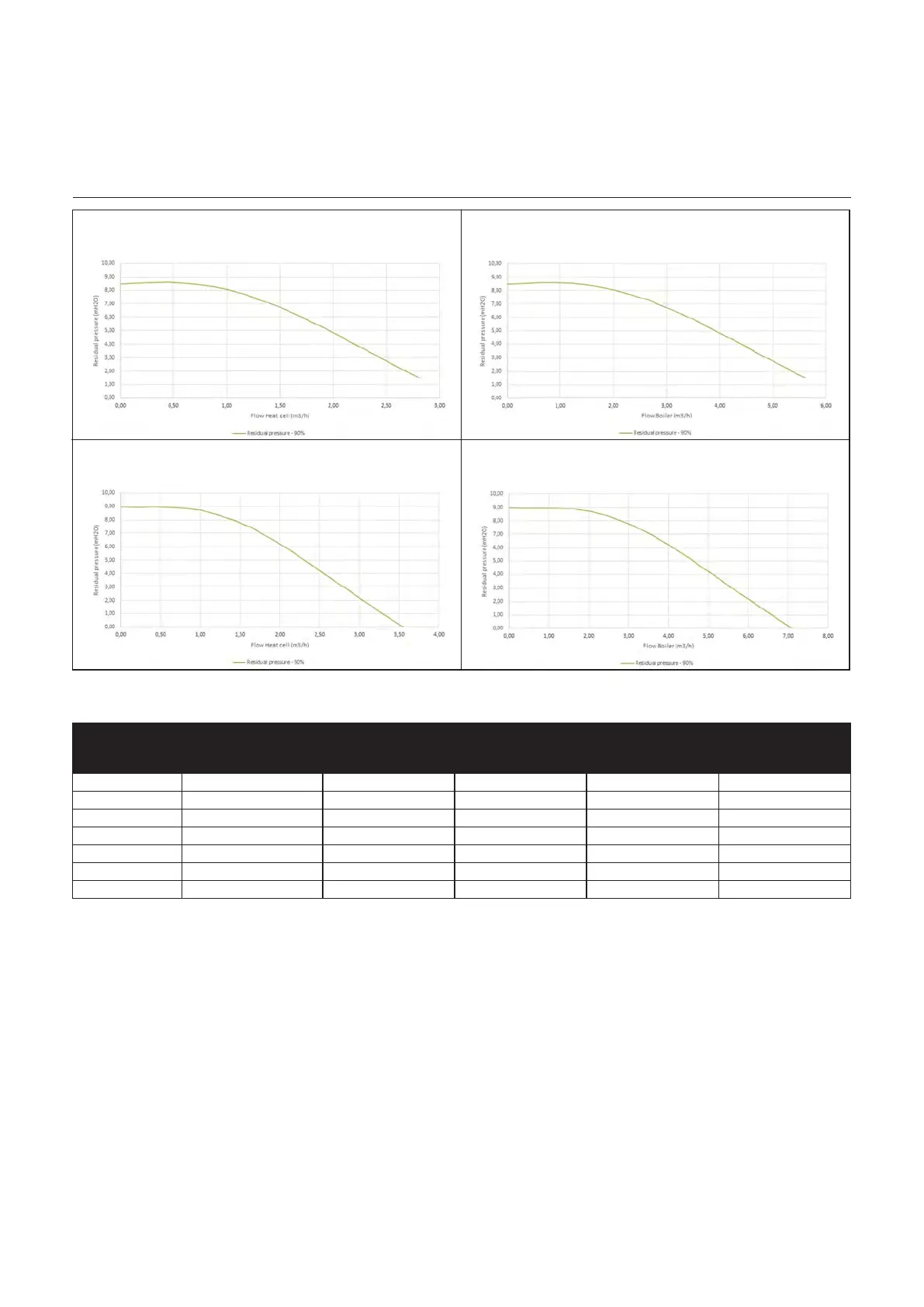

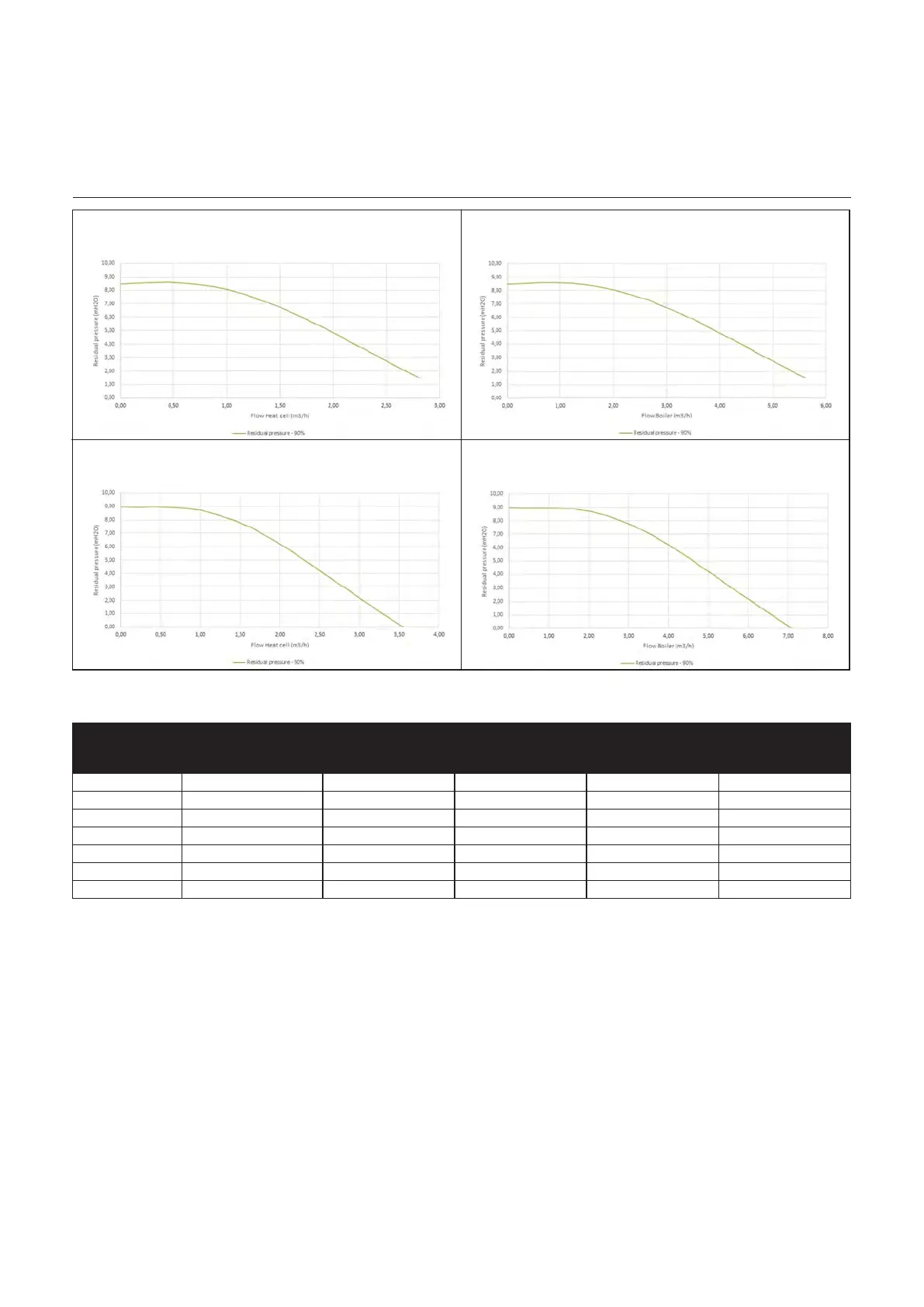

Pump head diagram, boiler type 60 – 70 Pump head diagram, boiler type 120 – 140

Pump head diagram, boiler type 100 Pump head diagram, boiler type 170 – 200

Boiler type Pump type Circulating water volume

(m

3

/h - l/min)

Residual head

(mH

2

O - mbar - kPa)

ΔT20 (K) ΔT25 (K) ΔT20 (K) ΔT25 (K)

60 1 x WILO PARA 8 2,44 - 40,7 1,95 - 32,6 3,0 - 296 - 29,6 5,1 - 495 -49,5

70 1 x WILO PARA 8 2,81 - 46,8 2,25 - 37,5 1,5 - 148 - 14,8 3,8 - 373 - 37,3

100 1 x WILO PARA 9 3,90 - 65,0 3,12 - 51,9 0,0 - 0 - 0,0 1,7 - 167 - 16,7

120 2 x WILO PARA 8 4,76 - 79,3 3,81 - 63,5 2,7 - 262 - 26,2 4,8 - 475 - 47,5

140 2 x WILO PARA 8 5,62 - 93,7 4,50 - 74,9 0,7 - 65 - 6,5 3,3 - 321 - 32,1

170 2 x WILO PARA 9 6,70 - 111,7 5,36 - 89,4 0,8 - 80 - 8,0 3,5 - 344 - 34,4

200 2 x WILO PARA 9 7,79 - 129,8 6,23 - 103,8 0,0 - 0 - 0,0 1,6 - 157 - 15,7

For single boiler installation the connection to a low velocity header and secondary circuit pump is strongly

suggested.

For installation of cascaded boilers the connection to a low velocity header and secondary circuit pump is

mandatory.

Temp dierential nominal

The WILO PARA 8 or 9 circulation pump, which is installed at the factory for the boiler, operates continuously and adapts its

pumpspeedtoheatrequirements(ΔT).

The ATG electronic continues to control the boiler’s output such that the boiler temperature setpoint is maintained.

Pumpspeedcontrolcontrolstheboilerpump’sspeedinawaythattheparameterizednominaltemperaturedierentialof

boilerreturnandboilerowismaintained.

Iftheeectivedierentialisgreaterthanthenominaldierential,thepump’sspeedisincreased,otherwiseitisdecreased.

Loading...

Loading...