0209

3

5

01106073

PageNotice Date

OPERATING

HANDBOOK

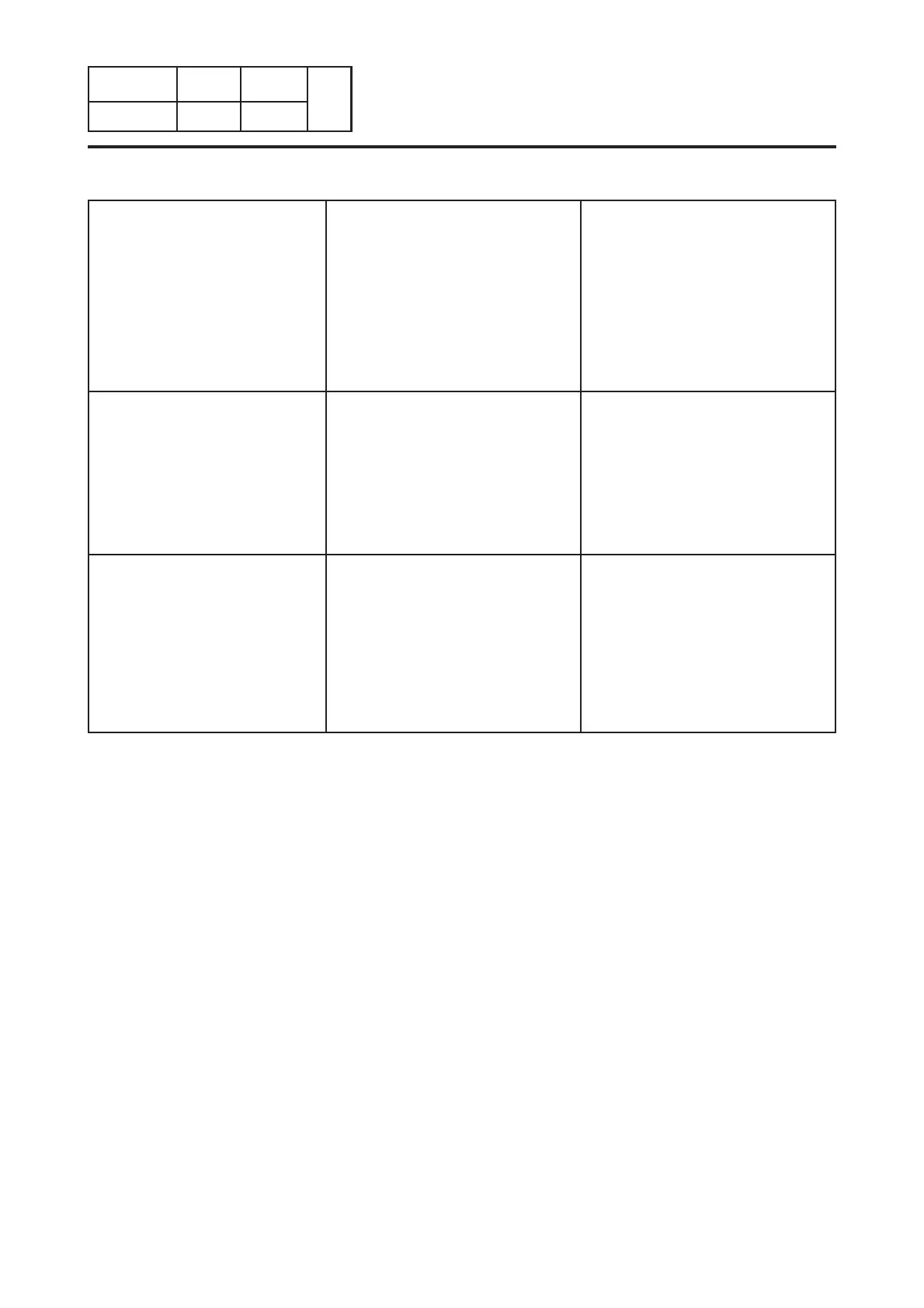

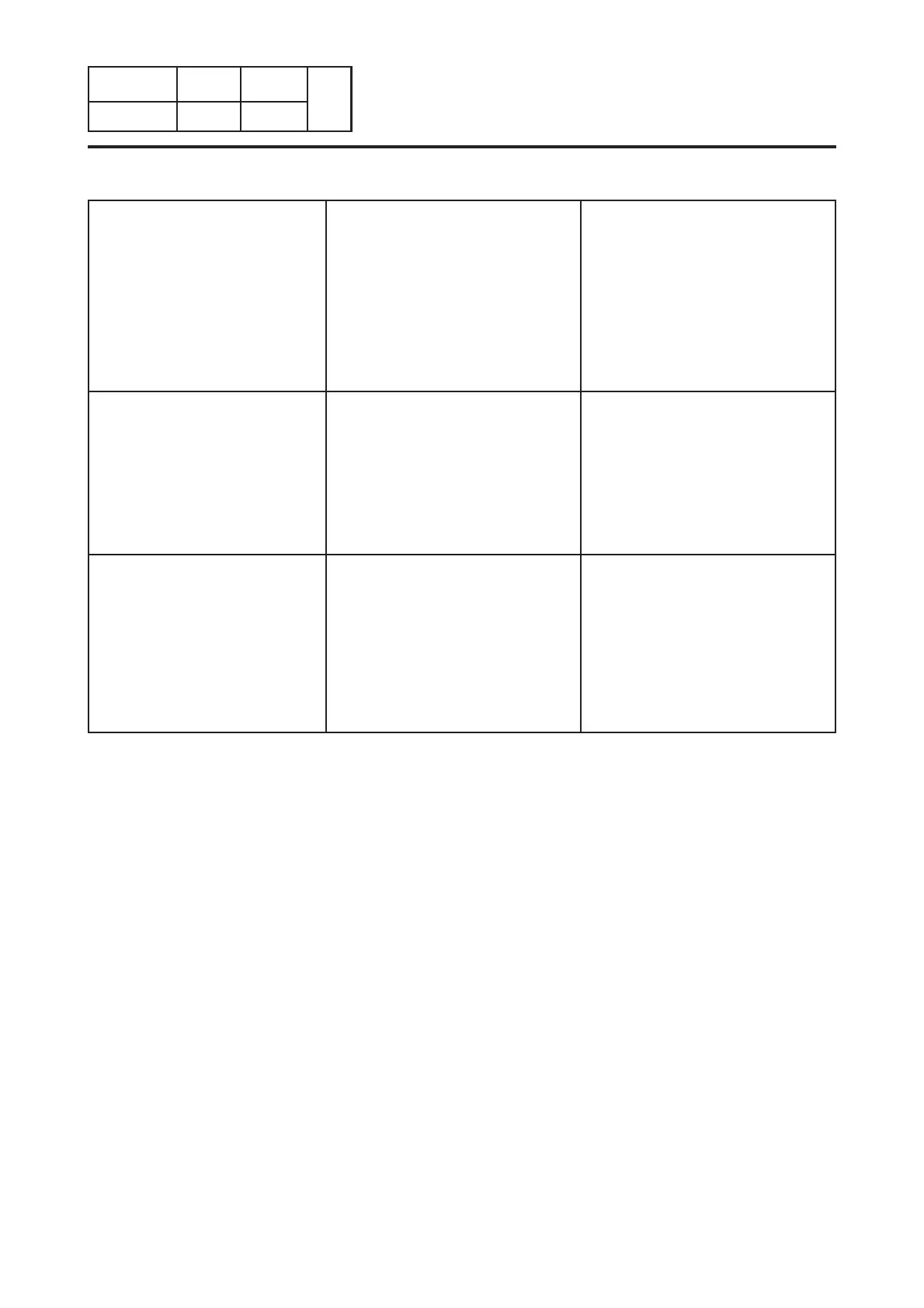

The machine temperature

drops

Check the sensor in the thermostat

regulation system.

Check the thermostat by measuring

the cylinder temperature with a

thermometer.

Check that the regulation shoe is in

contact with the cylinder.

The machine stops sud-

denly

Check the electric power supply.

Check the hand safety fl ap switches

S5 and S6.

Check the movement and ventilation

fans.

Check circuit breakers.

The folding system is

defective

Check that the photoelectric cell and

its refl ector are clean.

Check the folding arm limit switch.

Condensation given off by the linen

when still damp has affected the

operation of the photoelectric cell.

Check that the linen is perfectly dry

after being ironed.

Static electricity makes the folding diffi cult to achieve (machine with the folding

system only)

•

Synthetic textiles are used increasingly in laundry. The low rate of relative moisture on

output from drying allows high ironing speeds, which leads to production of harmful static

electricity when the linen is ironed in the machine.

• Use of softening and anti-static products attenuates this phenomenon.

• So, static electricity might cause important diffi culties at folding, especially when ironing

polyester/cotton. It si adviced to add a rincing anti-static liquid at the end of washing cycle

in order to reduce the formation of static elecricity when ironing.

Static electricity

•

Any friction generates static electricity. Remember the plastic ruler people rub over their

pullover to attract little bits of paper. With the same causes producing the same effects,

the linen being subjected to friction in the course of ironing, the rubbing of the linen

against the cylinder generates static electricity. If too much static electricity builds up,

friction has to be reduced, which can be done by removing the driving chain of the press-

cylinder to reduce the generation of static electricity.

5. Operating incidents

Encountered problem Cause of problem Solution

Loading...

Loading...