11

1.1 GENERAL

The ESAB 350mpi is a high performance constant

voltage (CV) and constant current (CC) inverter power

source designed to provide multi-process welding ca-

pabilities with dependability and ease of use. The

ESAB 350mpi is a self-contained unit which will pro-

duce power for Gas Metal Arc (MIG), Gas Tungsten

Arc (TIG) and Shielded Metal Arc (Stick) welding

without the use of optional apparatus.

For MIG (CV) welding, the ESAB 350mpi supports

welding a wide selection of ferrous and non-ferrous

alloys by utilizing Fixed Slope and inductance controls.

A special "Touch Tig" circuit eliminates the need for

high frequency or "scratch" starting when using the

TIG (CC) welding process. This feature provides smooth

starts without contaminating the electrode or the work.

The Stick (CC) welding mode provides adequate open

circuit voltage (70 V dc) for easy starts and re-starts as

well as an adjustable arc force which controls arc

penetration and wetting action.

The "Auto Fan" feature operates the cooling fan only

when the contactor is energized or when the internal

temperature exceeds the safe operating level. During

normal operation, the fan shuts down about 5 minutes

after the contactor disengages.

1.2 DUTY CYCLE

The ESAB 350mpi power source will operate on a 60%

duty cycle with a load of 350 amperes at 34 V dc (with

3-phase input). Duty cycle is defined as the ratio of

operating time to total time. Ratings are based on a 10-

minute cycle. The 60% duty cycle rating means that the

350 ampere, 34 volt rated load can be applied for a total

of 6 minutes and shut off for a total of 4 minutes in a 10-

minute period. If the welding current (or voltage) is

reduced, the duty cycle increases. Conversely, if the

welding current (or voltage) is increased, the duty cycle

will decrease. Refer to Table 1-1 and Figure 1-2.

1.3 VOLT-AMPERE CURVES

Figure 1-2 illustrates the static volt-ampere character-

istics for the power source in the MIG (CV), TIG (CC),

and Stick (CC) modes. The slant of these curves is

referred to as the slope and is generally defined as the

voltage drop per 100 amperes of current rise. These

curves show the output voltage available at any given

output current between the minimum and maximum

settings of the output control. Values for other settings

fall between the minimum and maximum curves.

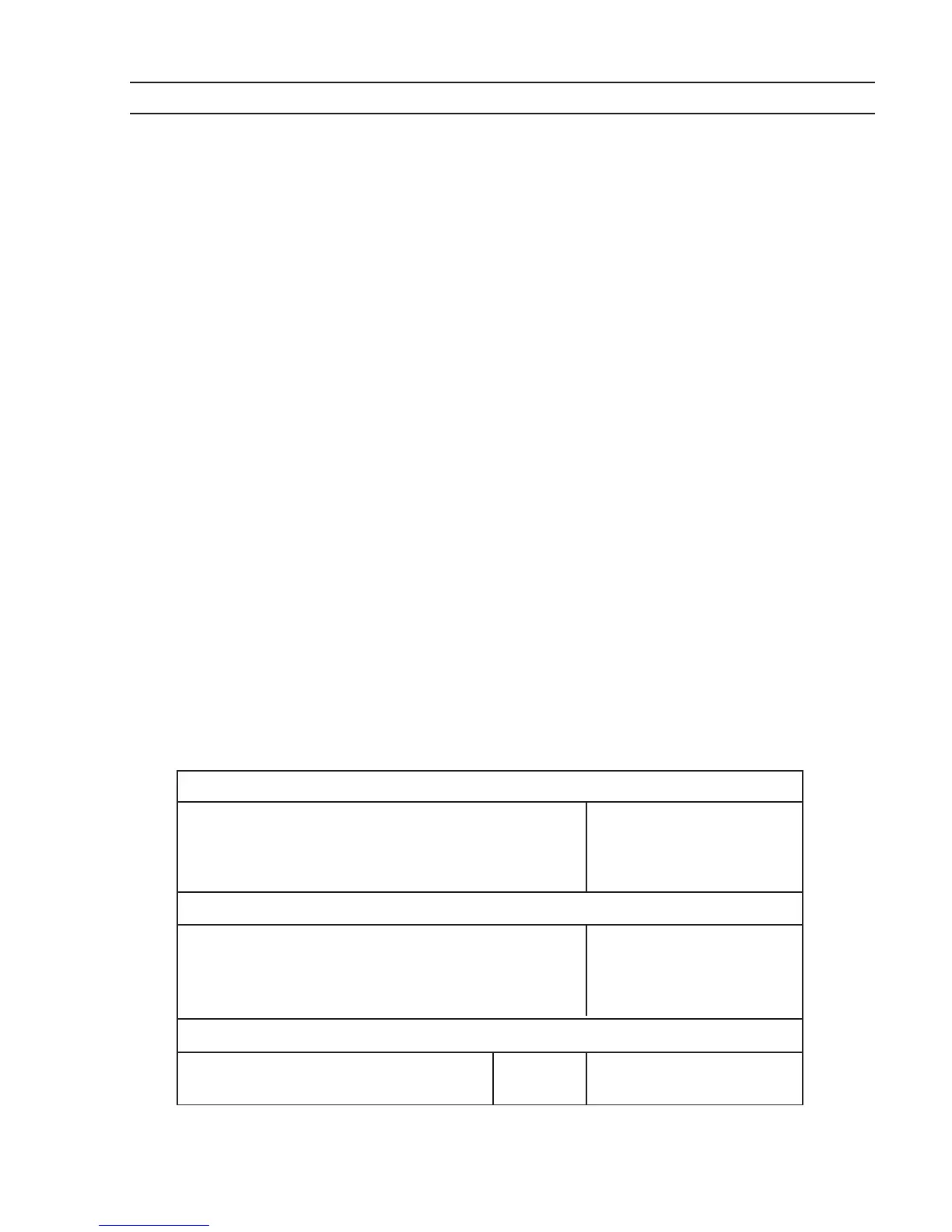

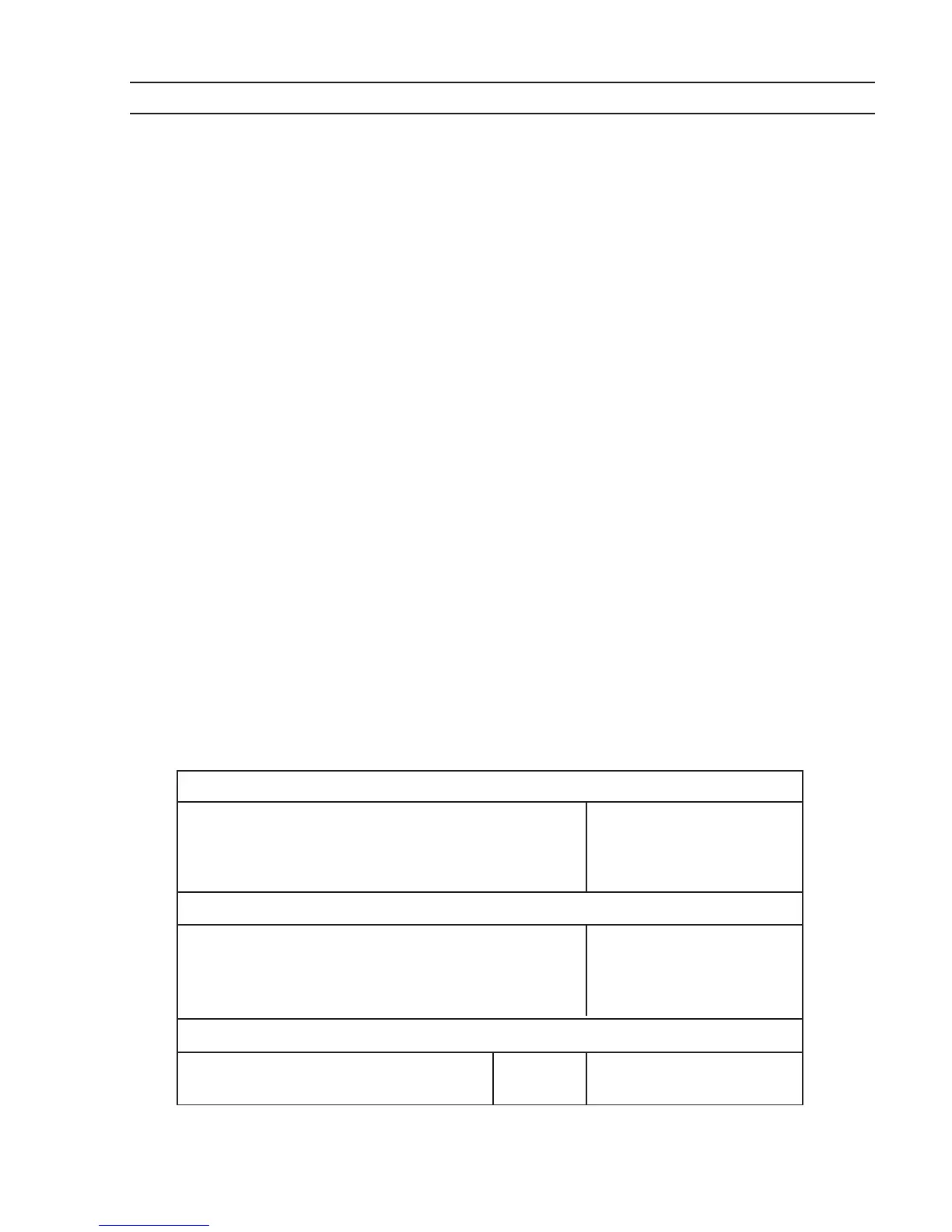

Table 1-1. Technical Specifications

RATED OUTPUT

100% Duty Cycle (3-phase input) 300 A @ 32 V dc

100% Duty Cycle (1-phase input) 225 A @ 29 V dc

60% Duty cycle (3-phase input) 350 A @ 34 V dc

Open-circuit Voltage (max) 70 V dc

PHYSICAL

Height 16.4 in. (417 mm)

Width 11.5 in. (292 mm)

Depth 29.8 in. (757 mm)

Weight 101 lbs (39 kg)

INPUT VOLTAGE AND CURRENT @ RATED 60% DUTY CYCLE LOAD

230/460 V ac models 3-phase 50/25 amps

1-phase 50/38

SECTION 1 DESCRIPTION

Loading...

Loading...