27

5.1 GENERAL

ELECTRIC SHOCK CAN KILL! Before attempting

inspection or work inside the power source, be

sure that all primary power to the machine has

been externally disconnected and the line (wall)

disconnect switch or circuit breaker is open.

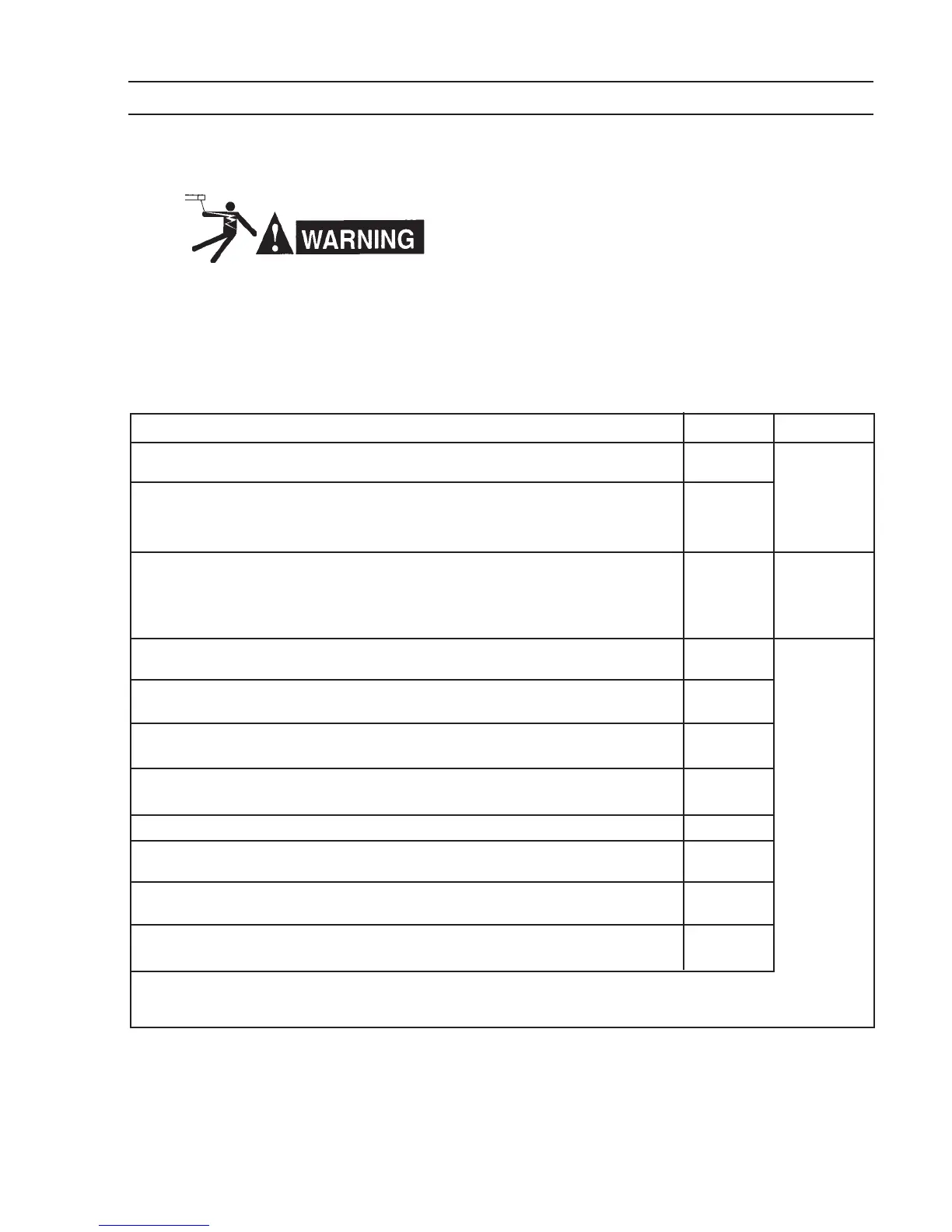

5.2 FUNCTIONALITY CHECK (TABLE 5-1)

The 350mpi Functionality Check should be used to

verify proper power source operation. Before perform-

ing the following checks, disconnect the remote con-

nections (WIRE FEEDER and REMOTE CONTROL)

from rear of power source and make sure there is no

load attached to the output terminals.

Table 5-1. 350mpi Functionality Check

YES NO

1. Are input power supply connections properly secured? Go to next

step

2. If using 3-phase power, are all three primary leads securely connected to Go to next Refer to

primary power switch. step. Section 2.

If using single-phase power, are black and white leads securely connected to

primary power switch?

.

3. Position power source controls as follows: --- --

PROCESS SELECTOR - STICK

CURRENT - MINIMUM

ARC FORCE - MINIMUM

4. Turn primary power switch to ON position. Does MAIN POWER light Go to next

illuminate? step.

5. Do digital meters show about 68.0 volts and 00.0 amps? Go to next

step.

7. Fan is not energized. Go to next

step.

8. Place PANEL/REMOTE switch in the PANEL position. Do digital meters Go to next Power source

show 00.0 volts and 00.0 amps? step. faulty.

9. Place PROCESS SELECTOR to MIG position.

10. Short electrode to work table , hold in place and return PROCESS SELECTOR to STICK. Does

digital meter show approximately 50 amps? Go tonext

step.

11. Rotate ARC FORCE fully clockwise. Does digital meter show about 150 Go to next

amps? step.

12. Rotate CURRENT fully clockwise. Does digital meter show about 500 Go to next

amps? step.

ESAB 350mpi has passed the functionality check. Problem may be in interconnection of gas lines or polarity of output

connectors. For technical assistance, refer to the Communication Guide located on the last page of this manual.

SECTION 5 TROUBLESHOOTING

Loading...

Loading...