15

SECTION 2 INSTALLATION

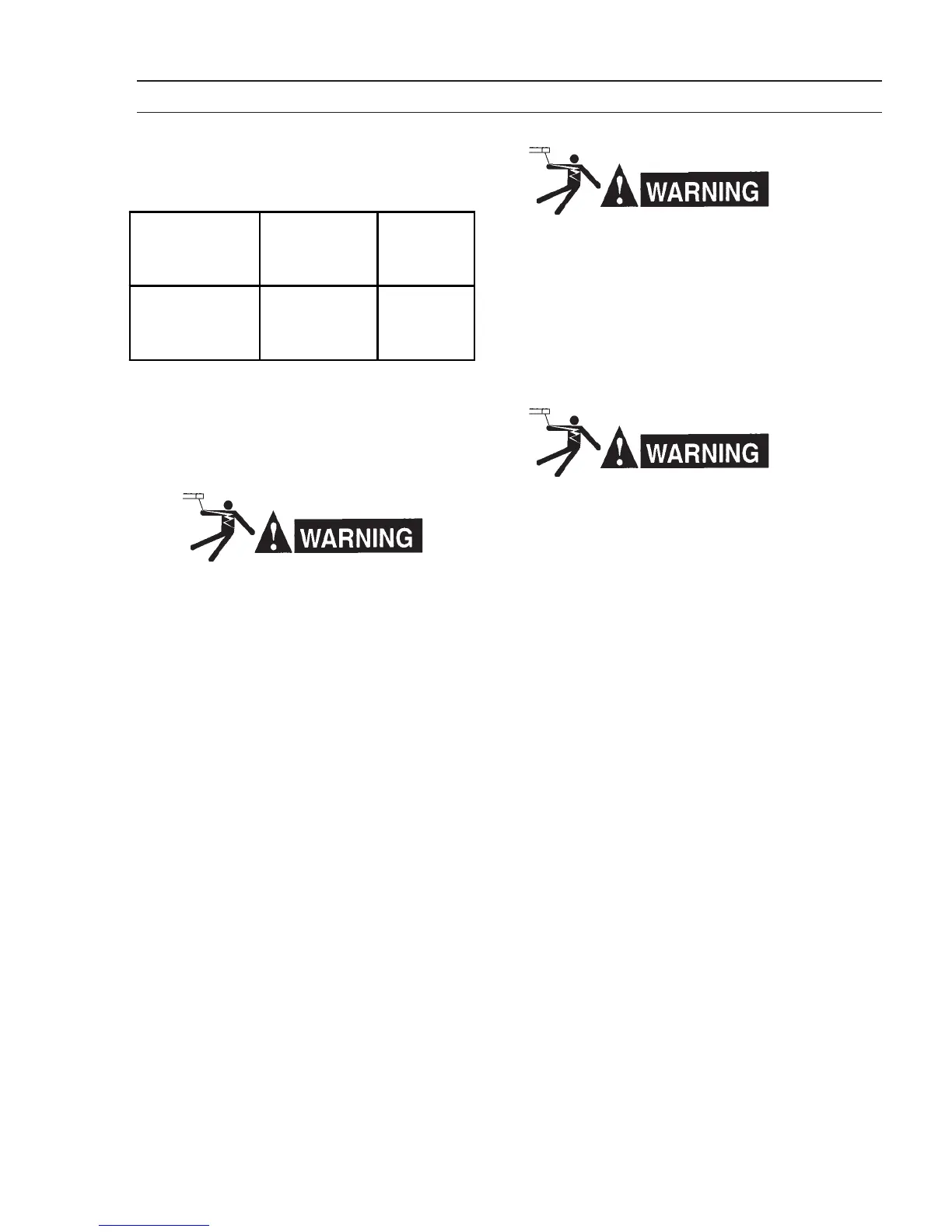

Rated Load

(3-phase input)

Volts Amps

Input &

Ground

Conductor*

CU/AWG (mm )

Time-Delay

Fuse Size

Amps

208 40

230 38

460 21

575 17

8 (10)

8 (10)

10 (6)

10 (6)

60

60

30

30

Table 2-1. Recommended Input Conductors and

Fuse Sizes

* Sizes per National Electric Code for 90 °C rated copper conductors

@ 30 °C ambient. Not more than three conductors in raceway or

cable. Local codes should be followed if they specify larger sizes

other than those listed above.

Use the following procedure to disconnect the factory-installed

cable and connect your own input power leads/cable.

ELECTRIC SHOCK CAN KILL! Make sure the ground

lead is at least twice as long as the input power

leads on the inside of the power source (see Figure

2-3). Ensure the strain relief and ground connec-

tion are securely tightened.

If these conditions are not met, the power source

chassis may become electrically "hot" if excessive

stress is placed on the input power cable.

If it is necessary to move the power source after it

has been connected to primary power, ensure that

the power source is turned OFF, and that an ad-

equate amount of "slack" is maintained in the input

power cable.

If you have single-phase input power and are using the

factory-installed power cable, you must change the

ON-OFF switch cable connections from three-phase to

single-phase configuration as follows:

1. Remove the 1/4" screws securing the top cover

and place them in a safe place.

2. Remove the top cover and set aside.

3. Loosen the ON-OFF switch cable connection

T3 located inside the power source.

4. Remove the red wire from cable connection T3.

ELECTRIC SHOCK CAN KILL! After the red wire

has been removed from L2, its center conductor is

exposed. This conductor must be covered with an

insulating material. Failure to do so properly could

cause a serious electrical shock hazard.

5. Re-attach the top cover with hardware re-

moved in step 1.

2.5 OUTPUT CONNECTIONS

ELECTRIC SHOCK CAN KILL! Before making any

connections to the power source output terminals,

make sure that all primary power input power is

deenergized (OFF) at the line (wall) disconnect

switch or circuit breaker.

Two male plug connectors (P/N 13792513) are sup-

plied with the ESAB 350mpi (see Figure 2-3). To

assemble the connectors onto each of your welding

cables, refer to the following instructions:

1. Slip the insulating boot over the end of the

cable.

2. Strip the wire approximately 1-1/2" (37 mm)

from the end.

3. Place the ferrule over the stripped wire end.

4. Place the male connector over the ferrule and

tighten the two Allen screws until they are flush

with the connector.

5. Slide the insulating boot over the assembly.

Refer to Tables 2-2 and 2-3 and Figures 2-4, 2-5, 2-6,

and 2-7 when attaching welding cables and optional

equipment to the ESAB 350mpi.

Particular attention should be paid to the electrical

resistance in the welding circuit; especially, the work

and work cable and when using a water-cooled torch.

High resistance in the welding circuit can cause perfor-

mance deterioration (loss of "heat" input, popping of

weld puddle, bushy arcs, etc.). It is recommended that

the power source/wire feeder and workpiece be placed

Loading...

Loading...