24

3.7.4 SPOOL BRAKE DRAG ADJUSTMENT

Spool brake disc friction should provide enough drag to keep

the wire spool from spinning freely after wire feed stops. If

adjustment is required, turn the adjusting screw inside the

spindle housing clockwise to increase drag or counterclock-

wise to decrease it. Drag should be just enough to limit

wire overrun.

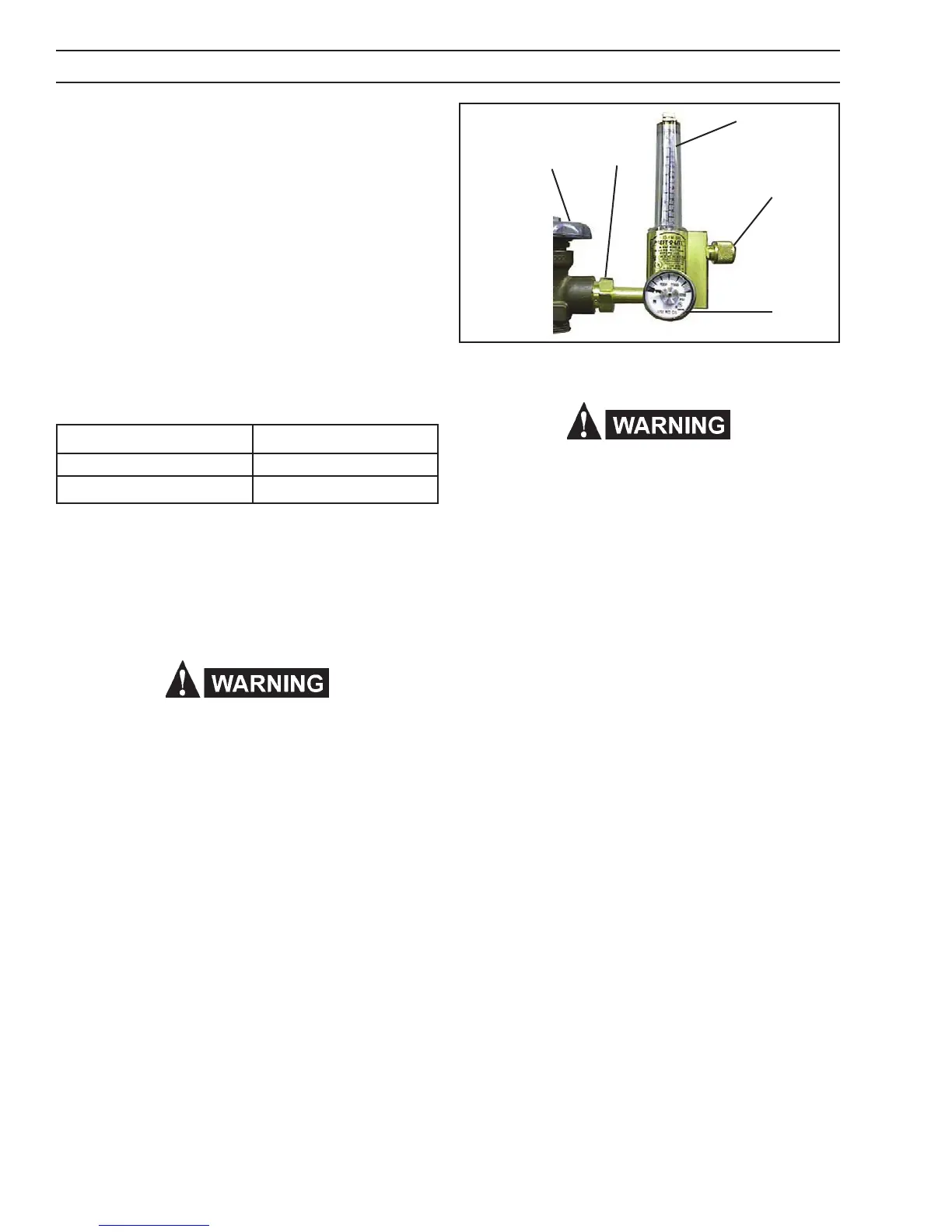

3.8 CONNECTION OF SHIELDING GAS SUPPLY

3.8.1 R33FM580 REGULATOR

The R-33-FM-580 regulator is an adjustable regulator designed

for use with Argon, Helium, and C-25 (75% Argon/25% CO

2

)

gas service. Table 2 table provides the recommended ow

ranges for the R-33-FM-580 regulator.

Argon 10-50 cfh

Helium 150-230 cfh

C-25 10-50 cfh

Table 2 - Typical Flow Rates

A. With the cylinder cap in place, CAREFULLY slide the

cylinder of gas onto the Multimaster 260 cylinder rack.

B. Secure the cylinder to the unit using the chain provid-

ed.

C. Unscrew the cylinder cap.

Do not clamp regulator cap in a vise or grip it with a pair

of pliers. Distortion of cap can jam the internal parts and

cause excessively high delivery pressure as well as weaken

the threaded joint to the regulator body. This may cause

the cap to y o and possibly injure personnel in area.

D. Open the cylinder valve slightly, for an instant, to blow

out any dust or dirt that may have collected in the valve

outlet. BE SURE to keep your face away from the valve

outlet to protect your eyes.

E. Attach the regulator to the cylinder valve. Align the

regulator so that the owmeter is vertical and then

tighten the connection nut with a 1-1/8 in. open end

or adjustable wrench. To prevent damaging the O-ring

seals and plastic tube, do not use the owmeter tube as

a‘handle’whenattachingtheregulator.

F. Close the ow control valve on the owmeter.

G. Attach the gas hose from the rear of the Multimaster 260

to the regulator outlet connection.

Never stand directly in front of or behind the regulator

when opening the cylinder valve. Always stand to one

side.

H. Open the cylinder valve SLOWLY a fraction of a turn. This

will prevent damage to the gauge and critical components

in the regulator. When the gauge needle stops moving,

then open the cylinder valve fully.

I. Using a leak test solution, such as P/N 998771 (8 oz. ctr)

or soapy water, test for leakage around the cylinder

valve stem, the regulator inlet connection, and the hose

connections at the regulator. Correct any leaks before

starting work.

3.8.1 TO REGULATE FLOW

Flow is controlled by adjusting the owmeter valve until de-

sired ow is indicated by the ball oat in the owmeter tube.

Always take the reading across the TOP of the ball.

Figure 10 - R-33 Regulator

Cylinder Valve

Connection

Nut

Flow Tube

Control Valve

Pressure

Gauge

SECTION 3 INSTALLATION

Loading...

Loading...