10

Maintenance (continued)

MOTOR AND SEAL SERVICE

NOTE: Refer to the Replacement Parts section for illustrations of part and part numbers referenced in this section.

DISASSEMBLY AND INSPECTION

1. Remove the screen, volute, and impeller as previously stated

and drain oil from the motor housing.

2. Loosen the gland nut (17) and slide it back on the cord (18).

3. Remove the hex nuts (20) and lock washers (21) from the

studs (26) and pull the housing end (19) from the motor

housing (25).

4. Disconnect the cord set (18) and check for damage or cracks.

Replace if required.

5. Remove the grommet (15) and friction rings (16) from the

housing end (19). Replace if damaged.

6. Pull the motor housing (25) from the bearing sleeve (9).

7. Remove the V-ring (6) from the shaft.

8. Loosen the motor screws and pull the bearing sleeve (9) with

the shaft seal (8) from the motor.

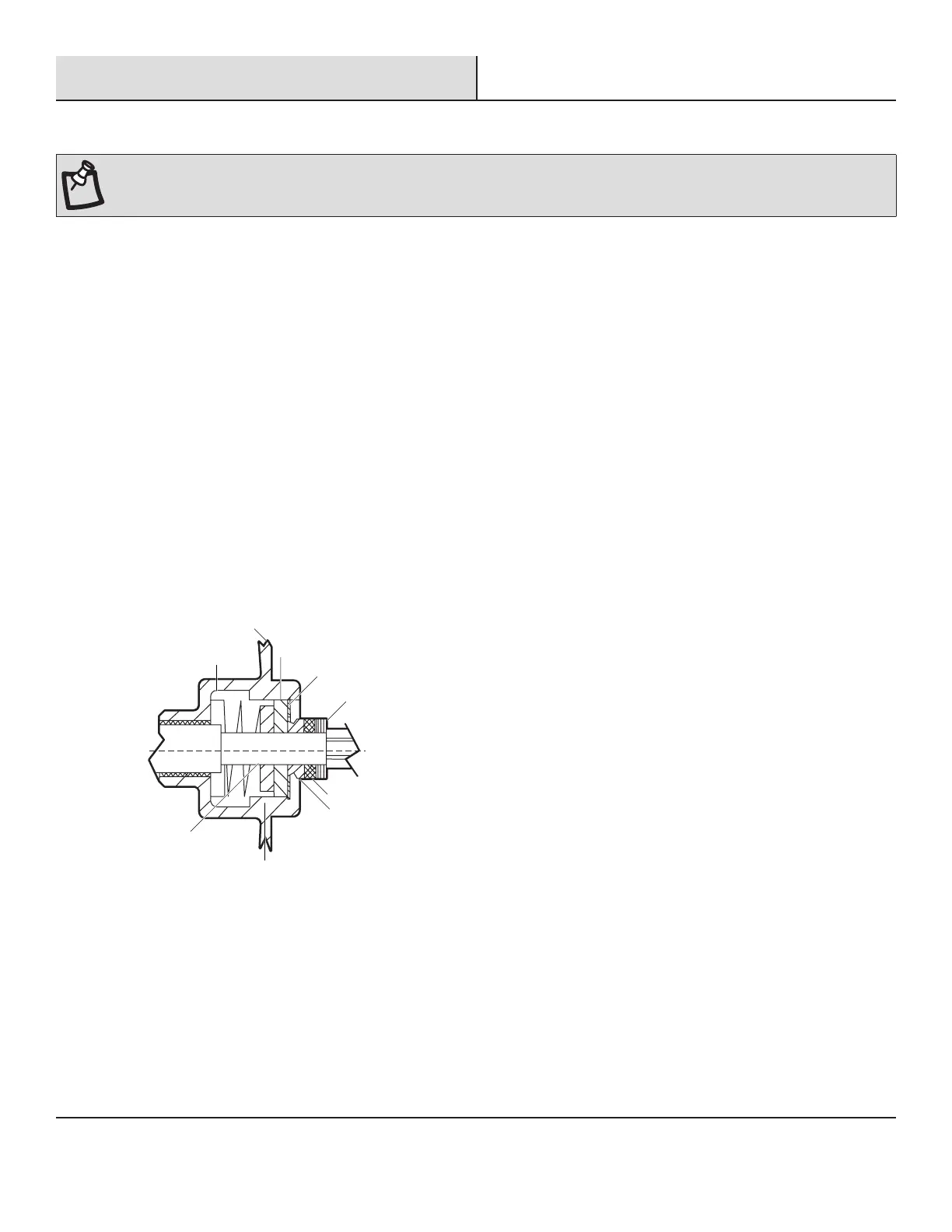

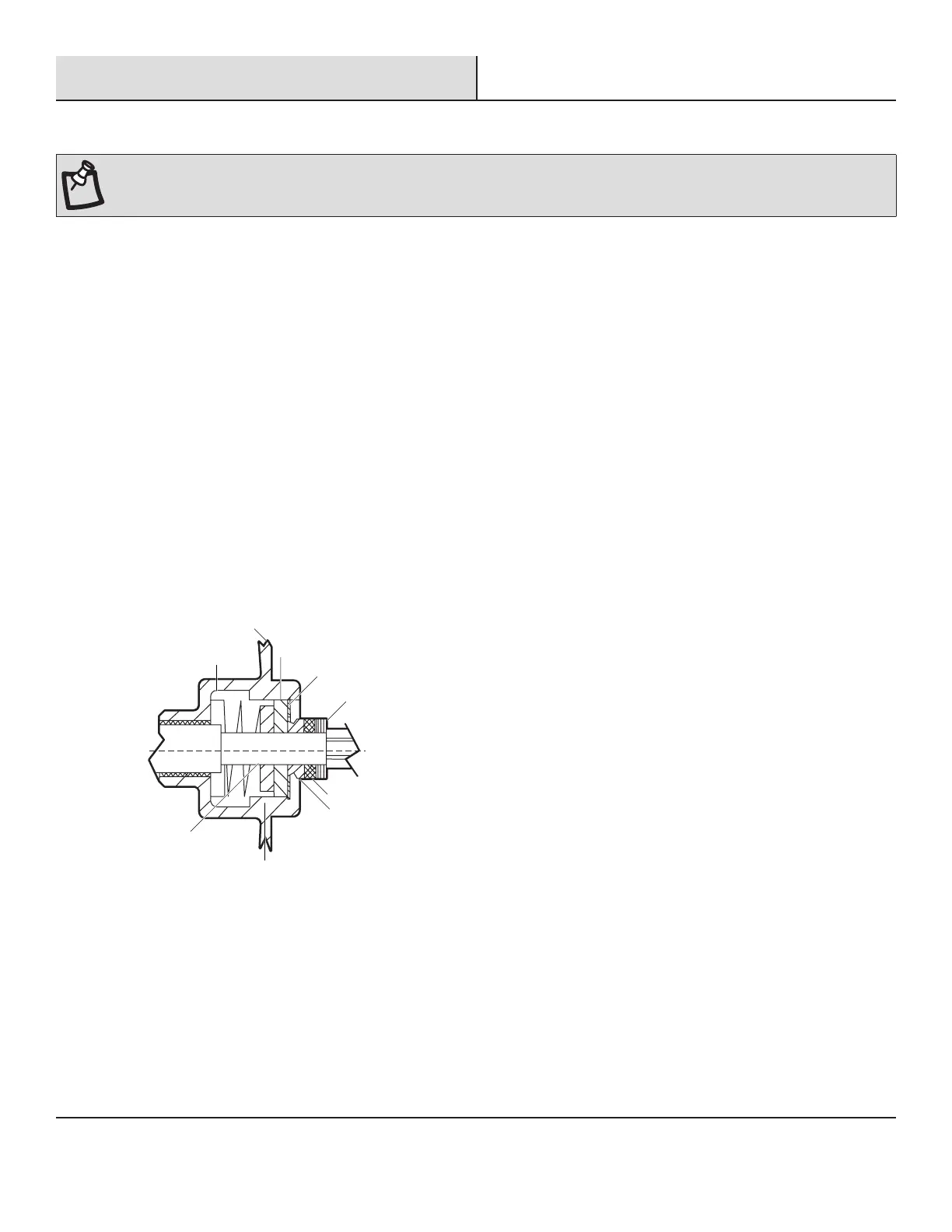

Rotating Memeber

Retainer

Bearing Sleeve

Stationary

Snap Ring

Shims

Spacer

V-Ring

Spring

9. Mark the location of the overload in relation to the bearing

sleeve (9).

10. Remove the retaining ring (7) and press the seal assembly (8)

out of the bearing sleeve.

11. Replace the complete seal if the seal shows signs of uneven

wear on seal faces, chips, or scratches. If replacing the seal,

remove the stationary by prying out with a screwdriver.

12. Examine the O-rings (23) and replace if damaged.

13. Check the motor capacitor (12) with an Ohm meter by rst

grounding the capacitor by placing a screwdriver across both

terminals and then removing the screwdriver. Replace the

capacitor if required.

14. Inspect the motor winding for shorts and check the resistance

values.

15. Check the rotor for wear. If the rotor or the stator windings are

defective, the complete motor must be replaced.

16. To test the overload, check the continuity between the black

and white wires.

Loading...

Loading...