12

Maintenance (continued)

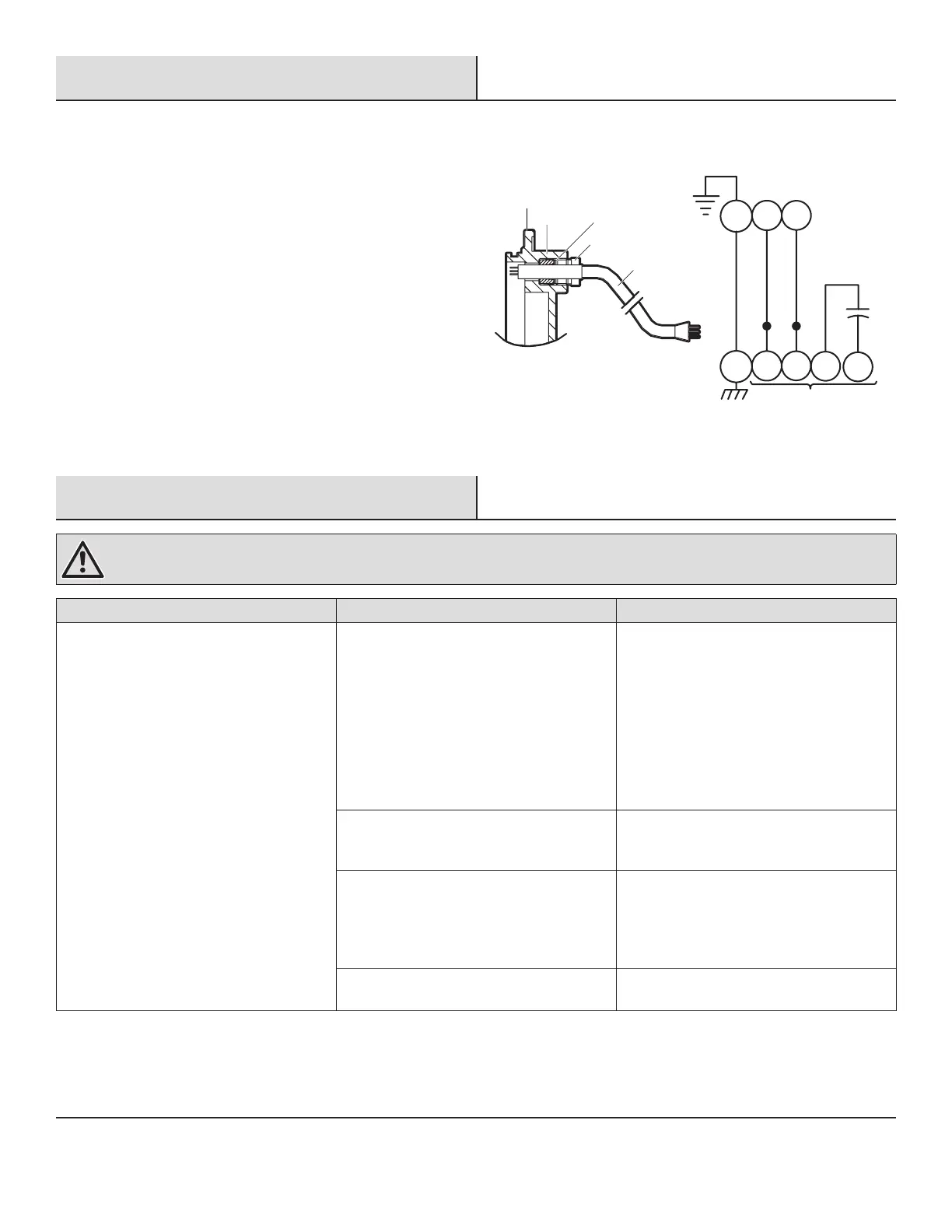

POWER CABLE CONNECTION

1. Place the gland nut (17), friction ring (16), and grommet (15)

onto the cord and slide the cord through the housing end (19).

2. Place the O-ring (23) into the groove on the housing end piece

(19) and slide the end piece onto the motor housing (25) being

careful not to damage the O-ring.

3. Place the pump support (22) onto the lower studs (26) and

place the lock washers (21) and hex nuts (20) onto the studs

and tighten.

4. Insert the grommet (15) and friction ring (16) into the housing

end piece (19).

5. Apply pipe sealant to the gland nut (17), screw into the end

piece, and torque the gland nut (17) to 17.5 ft. lbs to prevent

water leakage.

Motor Leads

Capacitor

Power Leads

Green

Black

White

GL1L2

GT1T2

19

15 16

17

18

Troubleshooting

WARNING: Ensure the pump is disconnected from the power source before attempting to service or remove any component.

Problem Solution Probable Cause

The pump will not turn. □ The electrical connection is poor, the

fuse is blown, there is a tripped breaker,

or other interruption of power.

□ The power supply is incorrect.

□ Check all electrical connections for

security.

□ Have an electrician measure the cur-

rent in the motor leads. If the current is

within ±20% of locked rotor Amps, the

impeller is probably locked.

□ If the current is 0, overload may be

tripped. Remove the power, allow the

pump to cool, then recheck the current.

The oat movement is restricted. Reposition the pump or clean the basin as

required to provide adequate clearance for

oat.

The motor is defective. □ Check the winding insulation

(Megger Test) and winding resistance.

If the check is outside of range, dry and

recheck. If still defective, replace per the

service instructions.

The liquid level is insufcient. □ Make sure the liquid level is at least

equal to the suggested turn-on point.

Loading...

Loading...