3.2 Fault and Warning Icon

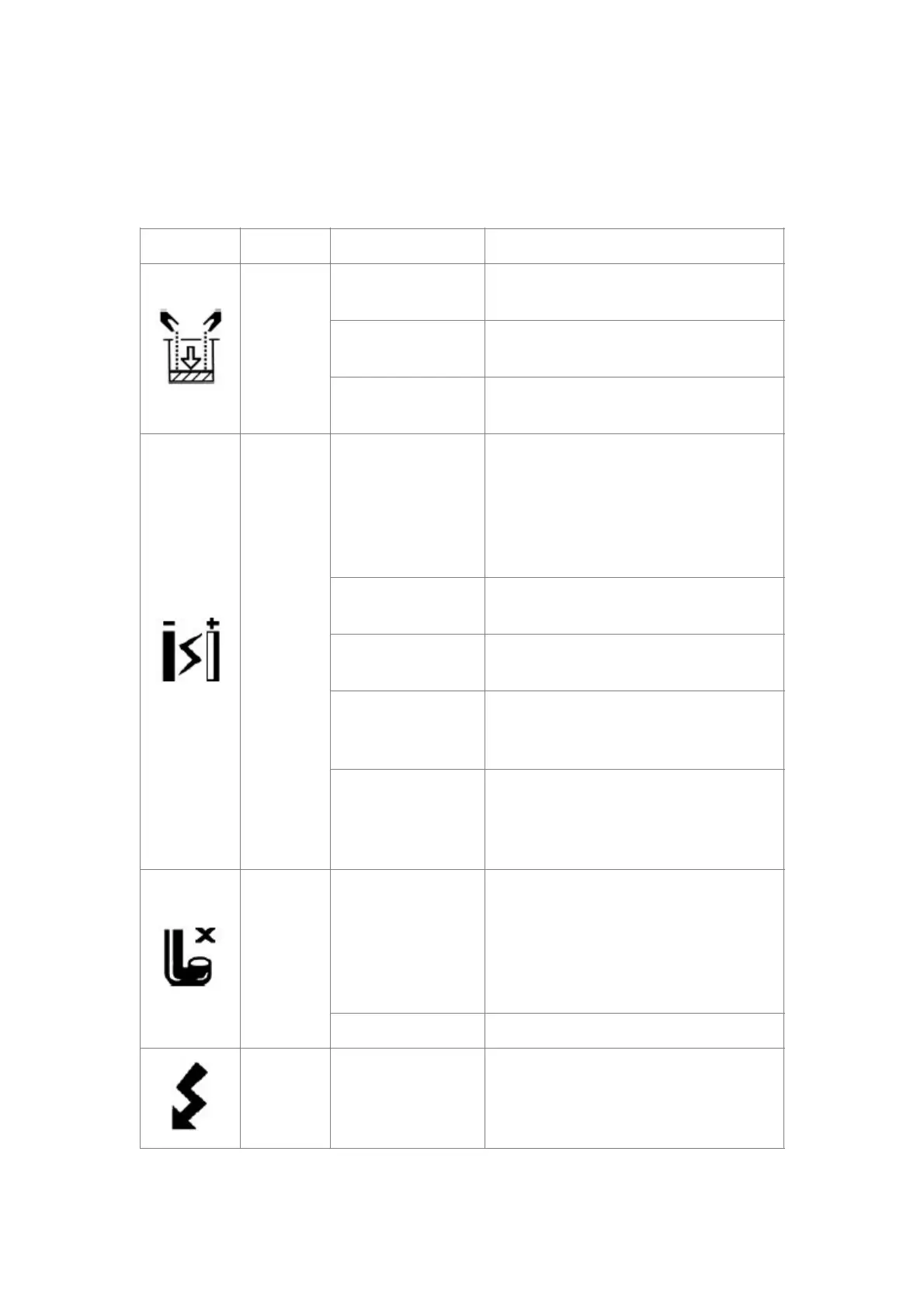

Fault Icons

Check the piping system with the

help of engineer.

Add ink until the icon disappears.

Ta ke V 2 d o w n a n d c l e an i t u p

with special cleaner.

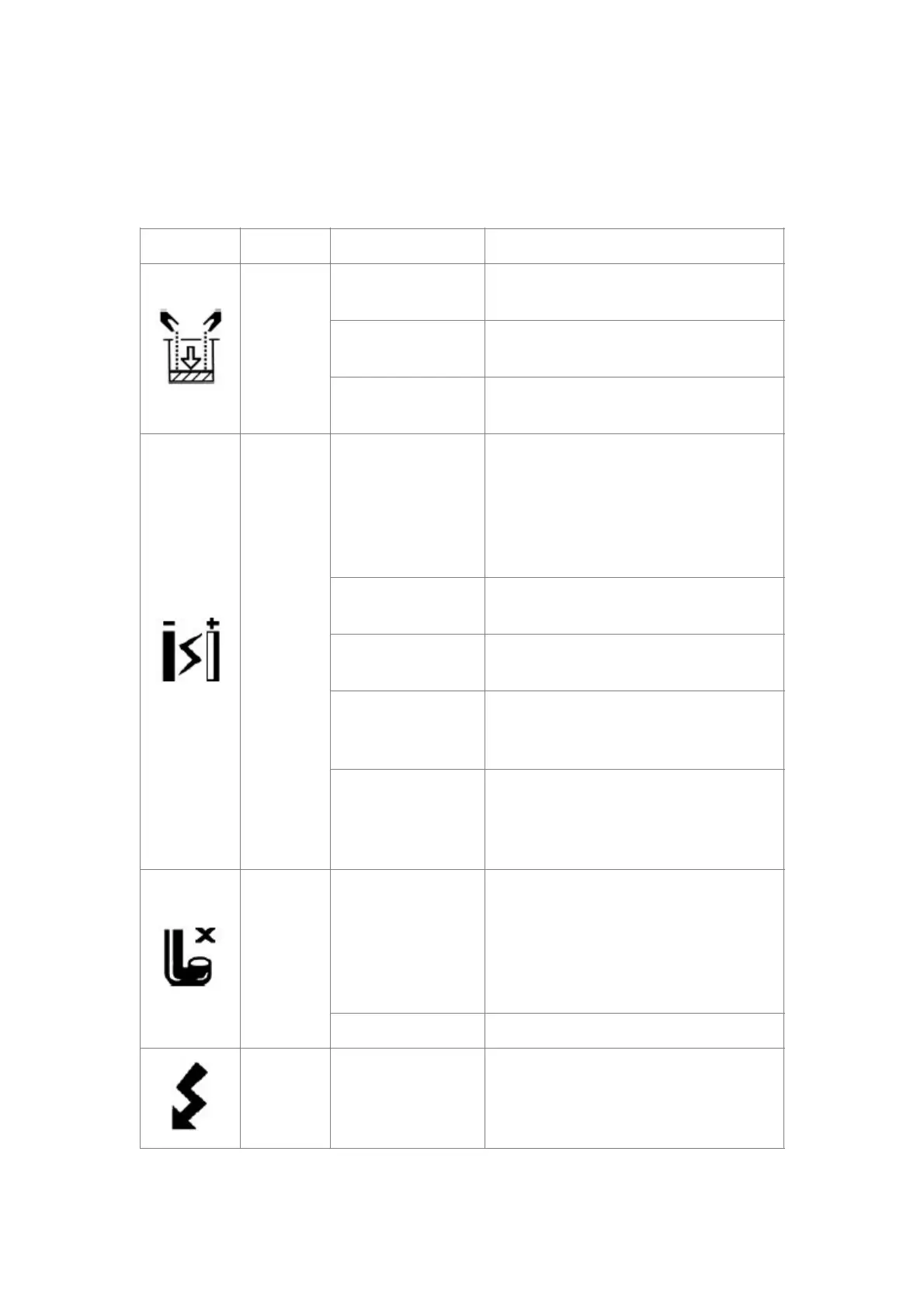

Do Nozzle Flush and Wash Nozzle

operation. Open the front cover

of the print head, and clean the

print head. Close the front cover

of the print head when all

components is dry and clean.

Observe the split point and adjust

it to the best condition.

incorrect ink

line position

Observe the ink line and adjust it

to the best position.

ink is out of

expiration date

or polluted

Eject the ink and clean the piping

system. Inject new ink.

Cleaning up the piping system

and change the fitter. Contact

the engineer for more

information.

Do Nozzle Flush and Wash Nozzle

operation. Open the front cover

of the print head, and clean the

print head. Close the front cover

of the print head when all

components are dry and clean.

Clean gutter until it is though.

High Voltage

Deflection Plate

accumulate ink

clean print head’s high voltage

deflection composition and dry it.

Contact the engineer for more

information.

Loading...

Loading...