Introduction Inspection and Maintenance

I–6

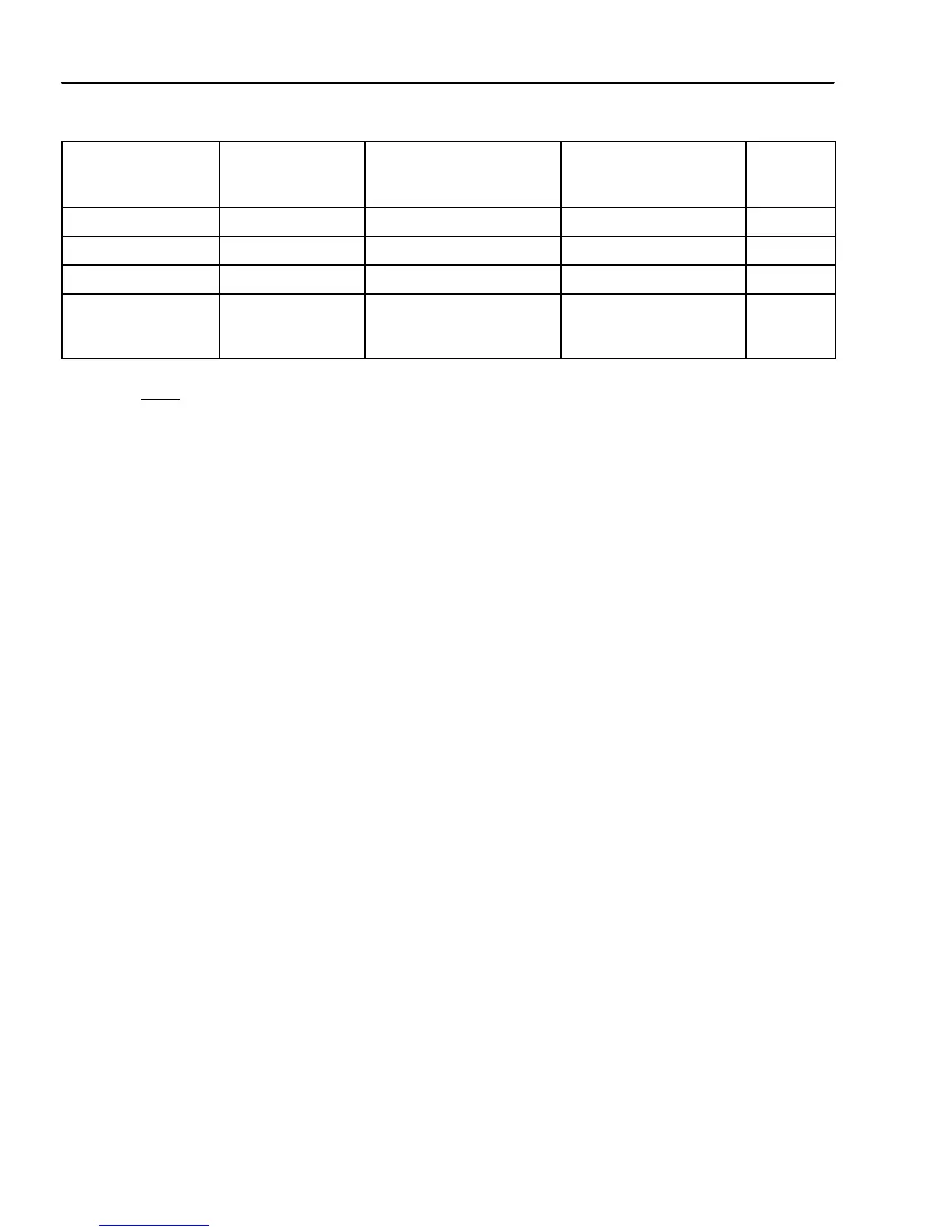

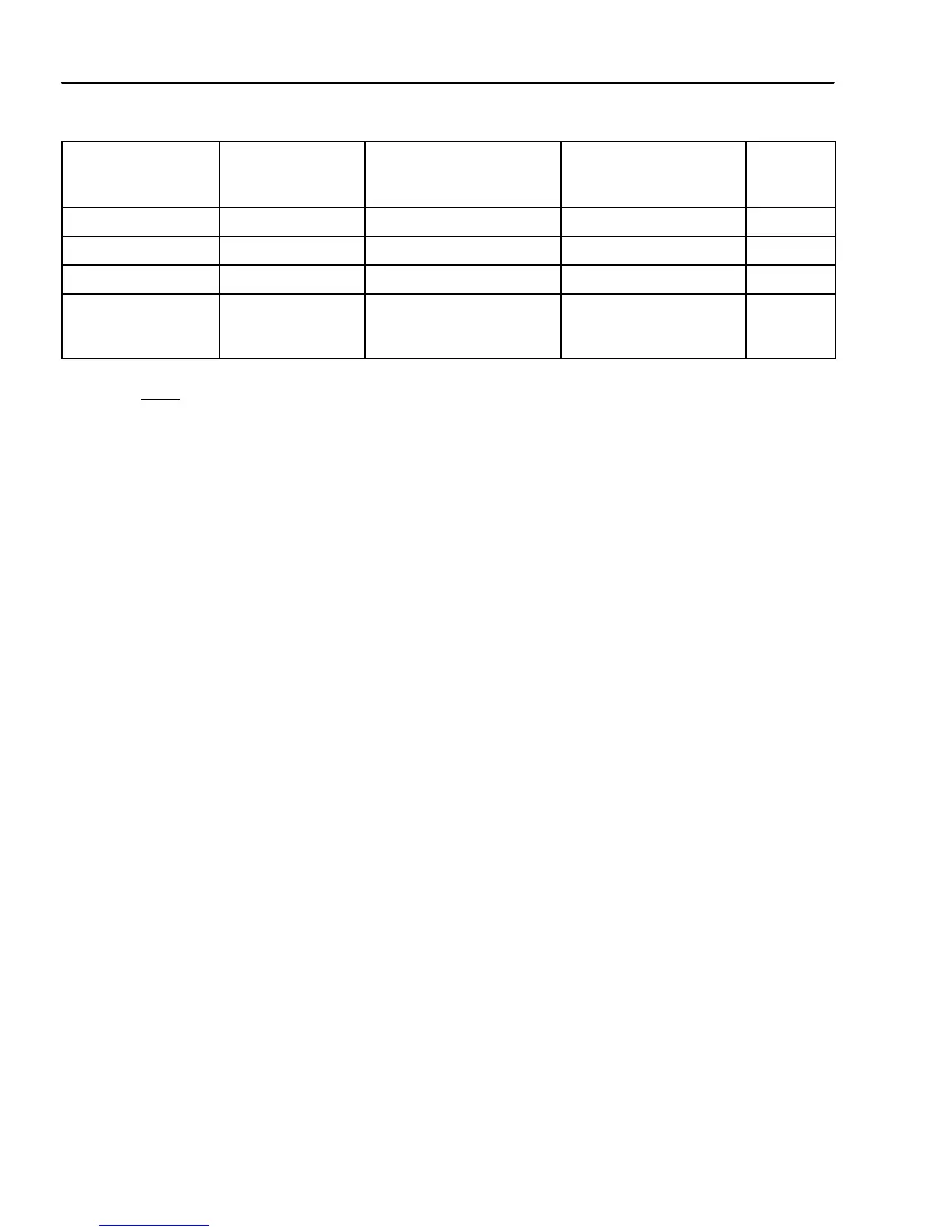

Table 1-1. VIGV Bushing Inspection Schedule

Frame Size

VIGV Bushing

Clearance Limits

for Bushing

Changeout (≥ inches)

Inspection

Interval

(Hours)

MS5001, 5002, 6001 403 Stainless Steel 158A7888, P004,5,6 0.050 5,000

MS5001, 5002, 6001 403 Stainless Steel 315A9681 or 339A9913 0.050 8,000

MS5001, 5002, 6001 GTD 450 315A9681 or 339A9913 0.075 16,000

MS7001, 9001 403 Stainless Steel

403 Stainless Steel

GTD 450

158A7888

315A9681 (or 339A9913)

315A9681 or 339A9913

0.070

0.070

0.100

8,000

8,000

16,000

Parts

GE Power Systems maintains a large volume of replacement parts to cover the requirements of gas tur-

bine owners. The parts protection system is designed for rapid response; however, there are periods of

heavy demand where certain parts may not be readily available for planned inspections.

It is strongly recommended that high probability parts be available on site prior to the start of inspections.

Spare and Renewal Parts sales personnel have responsibility for customer contact, to advise scheduling

of maintenance parts and identify additional parts needs. Local Spare and Renewal Parts sales personnel

can present operations spare parts recommendations and factor individual needs into gas turbine mainte-

nance philosophy as well as to provide for planned maintenance parts, including time tables and making

suitable recommendations concerning design improvements and modifications to improve reliability,

maintainability or reduce operating cost. In addition gas turbine parts programs such as interchangeabil-

ity, exchange plan, warehousing program, and repair and return policy can be identified.

Loading...

Loading...