Do you have a question about the gefran 600 and is the answer not in the manual?

| Input Type | Thermocouple, RTD, Voltage, Current |

|---|---|

| Output Type | Relay, SSR, Voltage, Current |

| Power Supply | 24V AC/DC, 100-240V AC |

| Dimensions | 48x96mm, 96x96mm |

| Communication | RS485 |

| Operating Temperature | 0...+50 °C / 32...+122 °F |

| Storage Temperature | -20...+70 °C / -4...+158 °F |

| Control Type | PID Controller |

Details panel mounting dimensions and cut-out requirements for the controller.

Details display, accuracy, input types, safety, and control output capabilities.

Details accepted input types like TC, RTD, PTC, NTC, and their ranges.

Describes output types (relay, logic, triac), maximum power, and cycle times.

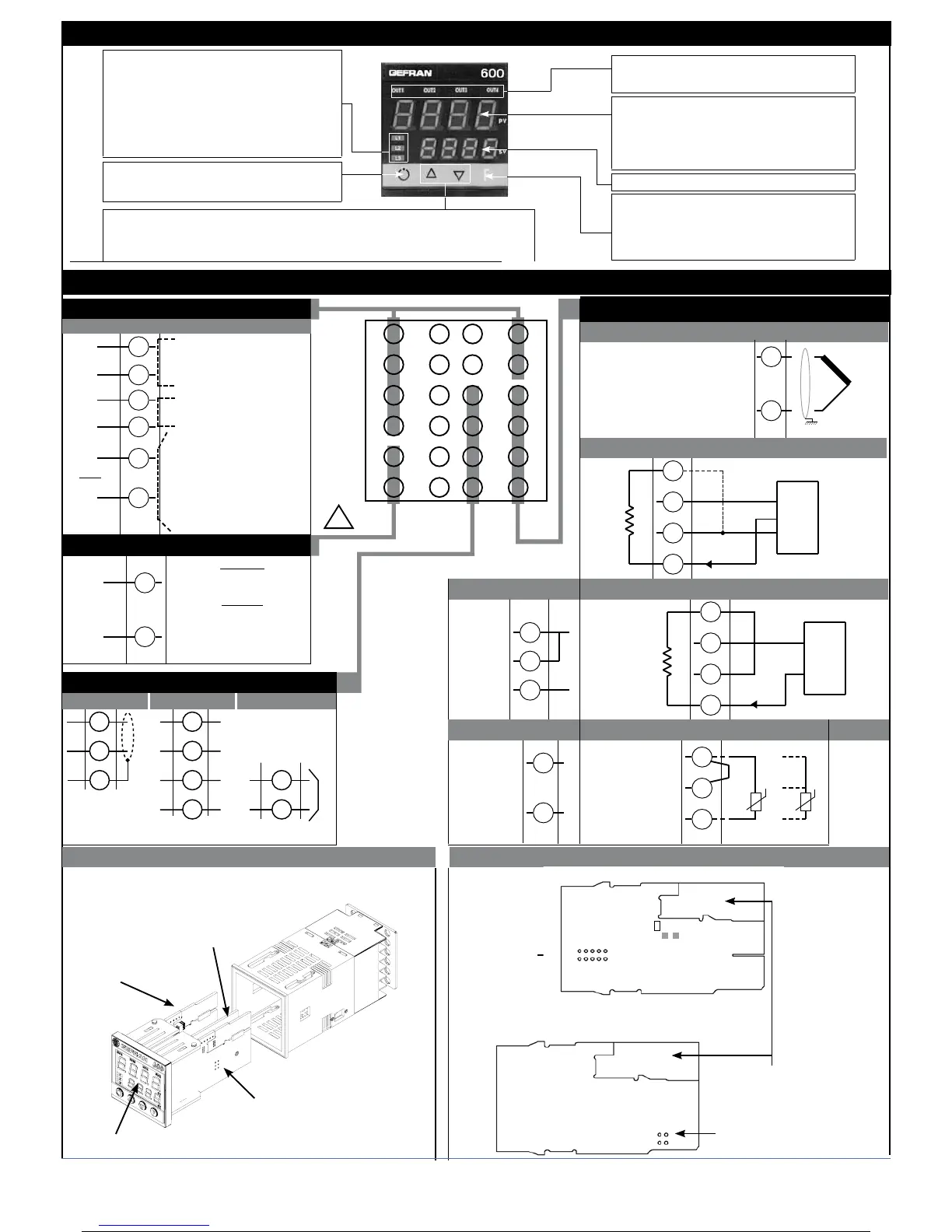

Explains function indicators, output states, SV display, and function keys on the faceplate.

Illustrates connections for ammeter, power supply, inputs, outputs, and serial communication.

Outlines the menu structure for accessing CFG, InP, Out, and Prot parameters.

Details settings for input, output, alarms, protection codes, and basic parameters.

Covers menu navigation, information display options, and software on/off switching.

Details settings like Proportional Band, Integral Time, Derivative Time for heating/cooling.

Configures input mapping to virtual instruments, scaling, filtering, and limits.

Assigns reference signals to outputs and configures alarm types and HB alarm.

Manages parameter access via protection codes and configures hardware features.

Configures alarm numbers, key functions, digital inputs, and LED behavior.

Sets up custom input linearization and guides user calibration for accuracy.

Explains the HB alarm functionality and the Hold function's behavior.

Details normal, symmetrical, and deviation alarms with graphical examples.

Explains how P, D, I actions affect process response and stability.

Provides guides for manual PID tuning, multisetting, and set gradient.

Details automatic PID parameter calculation methods.

Explains PID control modes and specific settings for cooling control.

Lists optional accessories like current transformers and PC interface kits.

Shows application examples like twin setpoint with ramp and hold.

Explains the coding for basic and expandable versions of the controller.

Provides critical warnings for installation, connection, and safe operation.

Emphasizes electrical safety, cable selection, grounding, and interference prevention.