0$,17(1$1&(

6(59,&,1*7+(+($7(;&+$1*(52)7+(%2,/(56+(//

The heat exchanger must be cleaned once the bur-

ner has been disassembled (paragraph 1 - section

X - MAINTENANCE).

- Sprinkle the heat exchanger with water. The wa-

ter is evacuated through the condensate evacua-

tion siphon,

- when reassembling the burner onto the boiler

shell check the correct positioning of the gasket.

&+(&.,1*$&&(6625,(6

- Check that the safety and control devices (3 bar

safety valve, air bleed, safety control box, etc.)

are operating properly.

- Check that the condensate drain siphon is clean

(remove it, clean it, replace it and then fill it with

water).

- Also check that neither the installation nor the

boiler present any water or fuel leaks (leaks may

produce a risk for safety and shorten the lifes-

pan).

- When it is frequently necessary to add water to

maintain pressure in the installation, even though

no leaks have been discovered, perform an ex-

pansion tank check (paragraph 4 - section X -

MAINTENANCE).

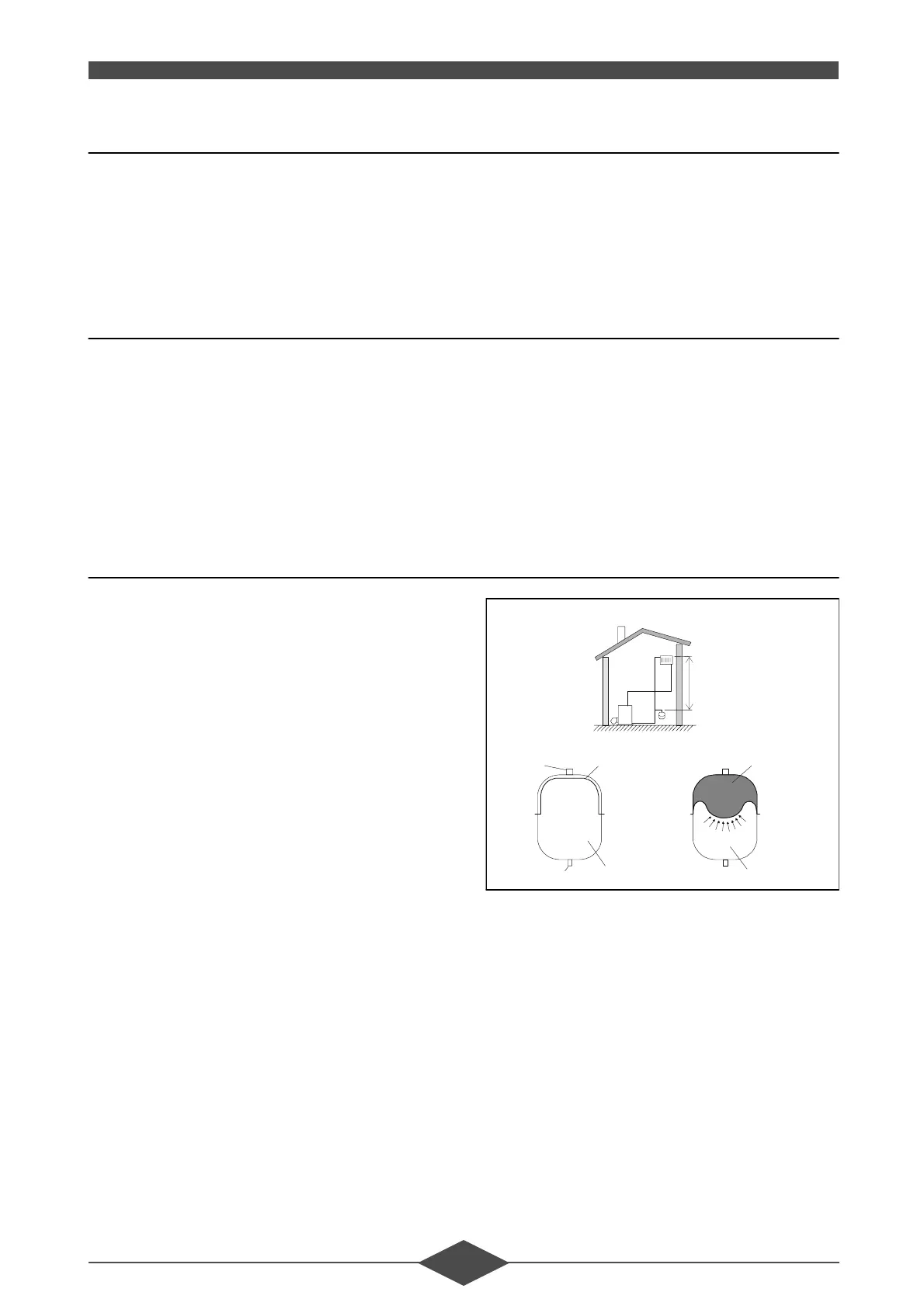

(;3$16,219(66(/35(,1)/$7,2135(6685(&+(&.

- Drop the pressure in the heating installation by

opening the drain cock or the safety valve (pres-

sure gauge reading under 0.5 bar).

- Check the pressure in the expansion vessel and

if necessary bring it back up to pressure, or repla-

ce it if the membrane is punctured (water present

in the inflating valve).

- To optimise the efficiency of the vessel:

• adjust its pre-inflation pressure in line with the

installation. It must correspond to the static

height of the installation (H) expressed in bars

(height between the highest point of the instal-

lation and the expansion tank, with 10 metres

= 1 bar),

• adjust the filling pressure of the installation to a

value of over 0.2 bar above the pre-inflation

pressure of the vessel (after totally bleeding

the air from the installation).

)LJ

H

Water inlet

volume

Inflating valve

Pressure rises as the

air is compressed

Max vessel

volume

Membrane

Loading...

Loading...