“C” Group: Intelligent Terminal Functions

Configuring

Drive Parameters

3–28

“C” Group: Intelligent Terminal Functions

The six input terminals 1, 2, 3, 4, 5, and 6 can be configured for any of 19 different

functions. The next two tables show how to configure the six terminals. The inputs are

logical, in that they are either OFF or ON. We define these states as OFF=0, and ON=1.

The inverter comes with default options for the six terminals. These default settings are

initially unique, each one having its own setting. Note that European and US versions

have different default settings. You can use any option on any terminal, and even use the

same option twice to create a logical OR (though usually not required).

NOTE: Terminal 5 has the ability to be a logical input, and to be an analog input for a

thermistor device when the PTC function (option code 19) is assigned to that terminal.

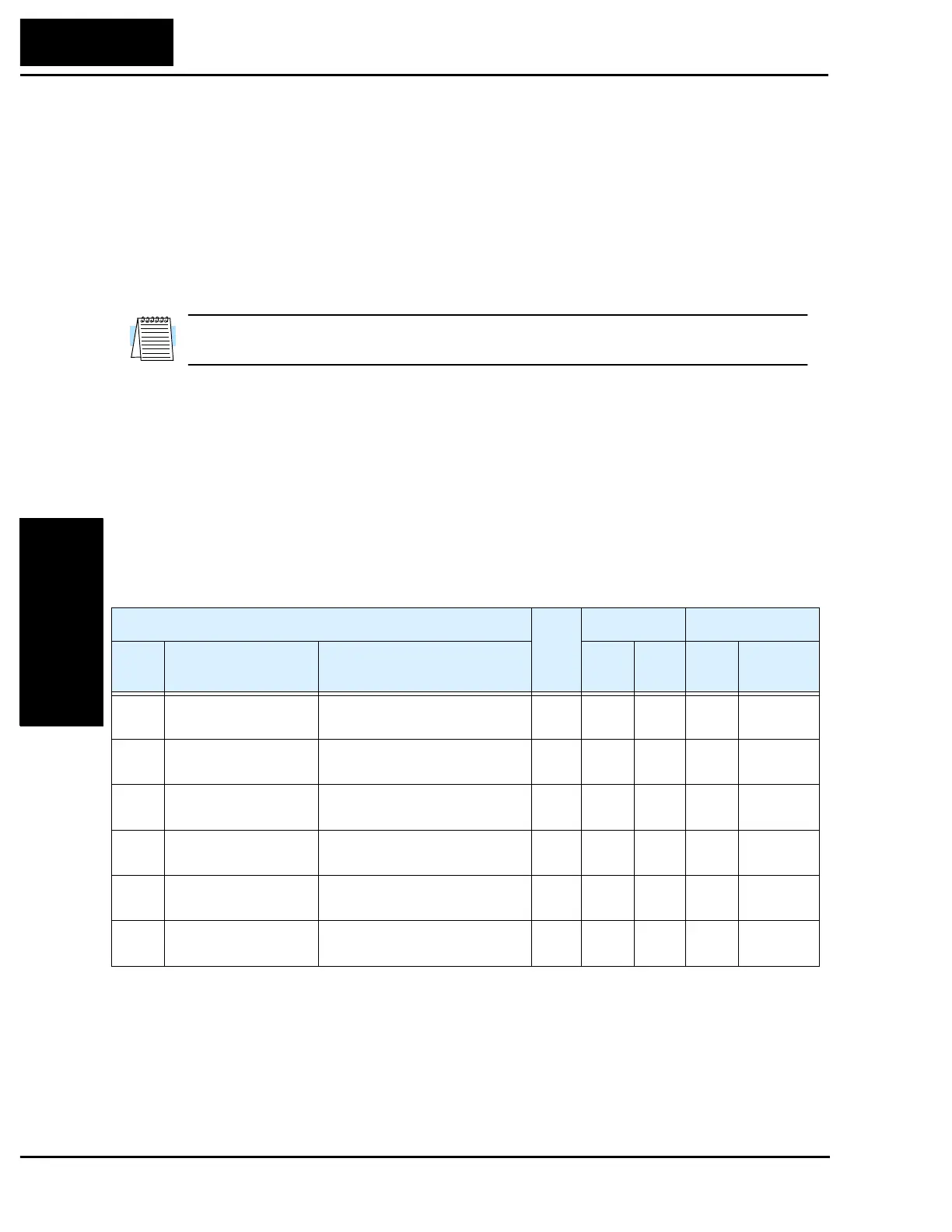

Input Terminal Configuration

Functions and Options –The function codes in the following table let you assign one of

nineteen options to any of the six logic inputs for the SJ100 inverters. The functions

C01through C06 configure the terminals 1 through 6 respectively. The “value” of these

particular parameters is not a scalar value, but it is a discrete number that selects one

option from two or more available options.

For example, if you set function C01=00, you have assigned option 00 (Forward Run) to

terminal 1. The option codes and the specifics of how each one works are in Chapter 4.

“C” Function

Run-

time

Edit

Defaults DOP,DRW,DOP+

Func.

Code

Name Description

EU/

US

Units

Func.

Code

Name

C01 Terminal 1 function Select function for terminal 1

18 options (see next section)

✘

00 — F34 IN-TM1

C02 Terminal 2 function Select function for terminal 2

18 options (see next section)

✘

01/01 — F34 IN-TM2

C03 Terminal 3 function Select function for terminal 3

18 options (see next section)

✘

02/16 — F34 IN-TM3

C04 Terminal 4 function Select function for terminal 4

18 options (see next section)

✘

03/13 — F34 IN-TM4

C05 Terminal 5 function Select function for terminal 5

19 options (see next section)

✘

18/09 — F34 IN-TM5

C06 Terminal 6 function Select function for terminal 6

18 options (see next section)

✘

09/18 — F34 IN-TM6

Loading...

Loading...