INSTALLATION INSTRUCTIONS

SIL

3

Capable

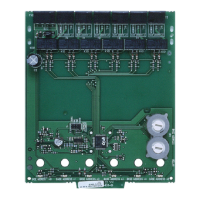

RM7898A

7800 SERIES Valve Proving

Primary Relay Modules

APPLICATION

The RM7898 is a microprocessor-based integrated burner

control for automatically fired gas, oil or combination fuel

single burner applications. The RM7898 system consist of a

relay module, subbase, amplifier, and purge card. Options

include Keyboard Display Module (KDM), Personal Computer

Interface, Data ControlBus™ Module, remote display

mounting, Expanded Annunciator and Combustion System

Manager® Software.

Functions provided by the RM7898 include automatic

burner sequencing, flame supervision, system status

indication, system or self-diagnostics and

troubleshooting.

This document covers the following 7800 Series Relay

Modules:

RM7898A1000

RM7898A1018

RM7898A2000

RM7898A2018

The RM7898 provides unique functions to a standard

primary control.

As received, the RM7898 offers the following features:

• Interrupted pilot with 10 second pilot flame establishing

period.

• Main valve operation with 10 second MFEP.

• Pre-Ignition Interlock (POC) input.

• Shutter-driven output when appropriate amplifier is

selected (R7861A, R7886A, R7851C).

• Blinking Fault Code Power LED on safety shutdown.

RM7898A1018 offers early spark shutoff when flame is

sensed.

Available features when appropriate terminals are

energized:

• Intermittent pilot T8 (Terminal 19).

• Direct spark feature for Valve Proving System (VPS)

(Terminal 18).

• Valve Proving System function (Terminal 17).

• See “Appendix b - ignition options” on page 25 for

examples of 24 single or dual fuel system combinations

with or without using the Valve Proving feature.

Programmable features using the S7800A1142 Keyboard

Display Module (KDM) (not included):

• Postpurge time—(up to 60 minutes).

• Valve Prove System features, including:

—VPS test time

— When in burner sequence to conduct VPS time

(Never, Before, After, Both or Split):

NOTE: The S7800A1142 Series 5 or higher can be pro-

grammed for ModBus Communication. (See 65-0288

Spec Sheet.)

At commissioning time, the Valve Proving System may be

scheduled to occur at one of five different times:

1. Never—Device default as received; valve proving

does not occur. (Demand wired to Terminal 6.)

2. Before—Valve proving after standby and safe start

check, prior to ignition trials, concurrent with Pre-

Purge.

3. After—Valve proving occurs after the Run state

before the device goes to Standby, concurrent with

postpurge.

4. Both—Valve proving occurs at both times Before and

After noted above.

5.

Split—The Main Valve 2 (MV2) (high pressure) seat test

is performed at the Before time and the Main Valve 1

(MV1) (low pressure) seat test is performed during the

After time.

To perform Valve Proving, it must be commissioned and

Demand Input (Terminal 17) must be used.

The following assumptions apply when using the RM7898

Valve Proving testing.

Fig. 1. Valve Proving System—simplified diagram.

MV1

MV2

VP

SW.

M24161

OUTLET

INLET

1

CAUTION: VALVE ENERGIZING TIMING IS BASED ON HONEYWELL VALVE

OPENING TIMES OF 13 SECONDS MAXIMUM.

− FOR VALVES WITH TIMINGS GREATER THAN 13

SECONDS OR THOSE THAT DO NOT OPEN THE ACTIVE

VALVE WITHIN THE ENERGIZED TIME, A BYPASS

SOLENOID VALVE (1/4”, 120 VAC) IS REQUIRED TO

OBTAIN THE PROPER TEST PRESSURES.

− THE BYPASS VALVE WILL BE WIRED IN PARALLEL TO THE

VALVE IT IS BYPASSING (TERMINAL 9 FOR MV1 OR

TERMINAL 21 FOR MV2).

1