HT4400 Instruction Manual e-7

2

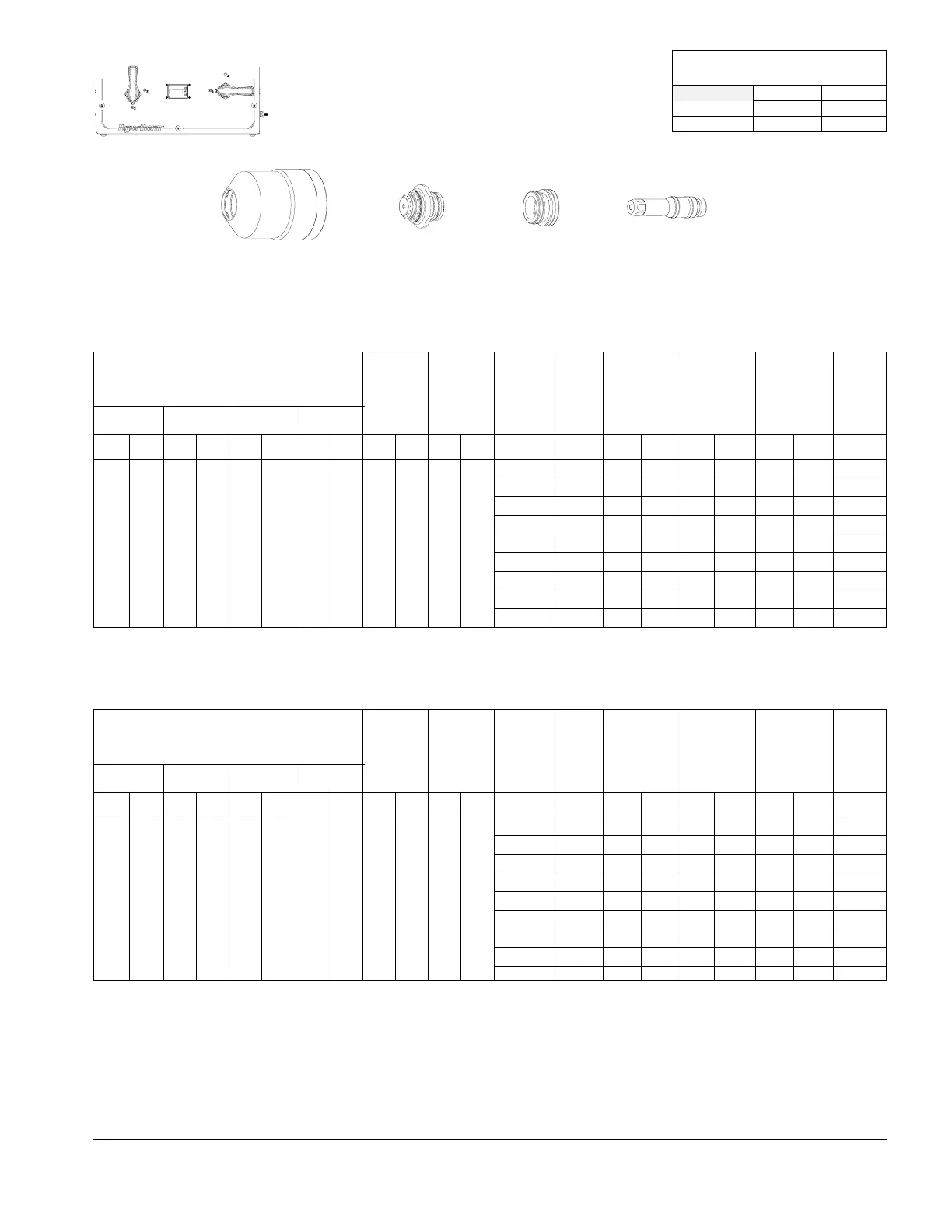

Stainless Steel

N

2

Plasma / O

2

-N

2

Shield

200 Amps

120786

Retaining Cap

120794

Nozzle

120853

Swirl Ring

120855

Electrode

* Piercing not recommended

Minimum inlet pressures remain at one setting of 140 psi (9.6 bar) for all material thickness.

Approximate pressures while cutting in RUN mode: PG1 49

PG2 33

Flow Rates @ 140 psi / 9.6 bar

(scfh / slh)

N

2

O

2

Preflow 211.4 / 5986 56.1 / 1589

Cutflow 200.6 / 5680 36.6 / 1036

3/16 130 .125 3 135 3430 .250 6 0.4

1/4 135 .125 3 120 3050 .250 6 0.5

3/8 135 .125 3 100 2540 .250 6 1

1/2 140 .157 4 75 1900 .314 8 2

5/8 140 .157 4 60 1520 .314 8 2

3/4 145 .188 5 45 1140 .375 10 2.5

7/8 145 .250 6 35 890 .500 12 3.0

1 150 .250 6 20 510 * * *

1-1/4 160 .250 6 15 380 * * *

ENGLISH

Material

Thickness

Plasma PlasmaShield Shield

MV1 MV2 MV3 MV4 MV5 MV6 MV7 PG1 PG2 PG1 PG2 inches Volts in. mm ipm mm/m in. mm seconds

Test

Preflow

Verify

(psi)

Test

Cutflow

Verify

(psi)

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce

Delay

Time

Test Preflow and Cutflow Adjust

(psi)

43 34 30 40 0 5 8 27 45 37 36

5 130 3 .125 3266 129 6 .250 0.4

6 135 3 .125 3226 127 6 .250 0.5

10 135 3 .125 2419 95 6 .250 1

12 140 4 .157 2016 79 6 .314 2

15 140 4 .157 1628 64 8 .314 2

20 145 5 .188 1089 43 10 .375 2.5

22 145 6 .250 898 35 12 .500 3.0

25 150 6 .250 516 20 * * *

30 160 6 .250 415 16 * * *

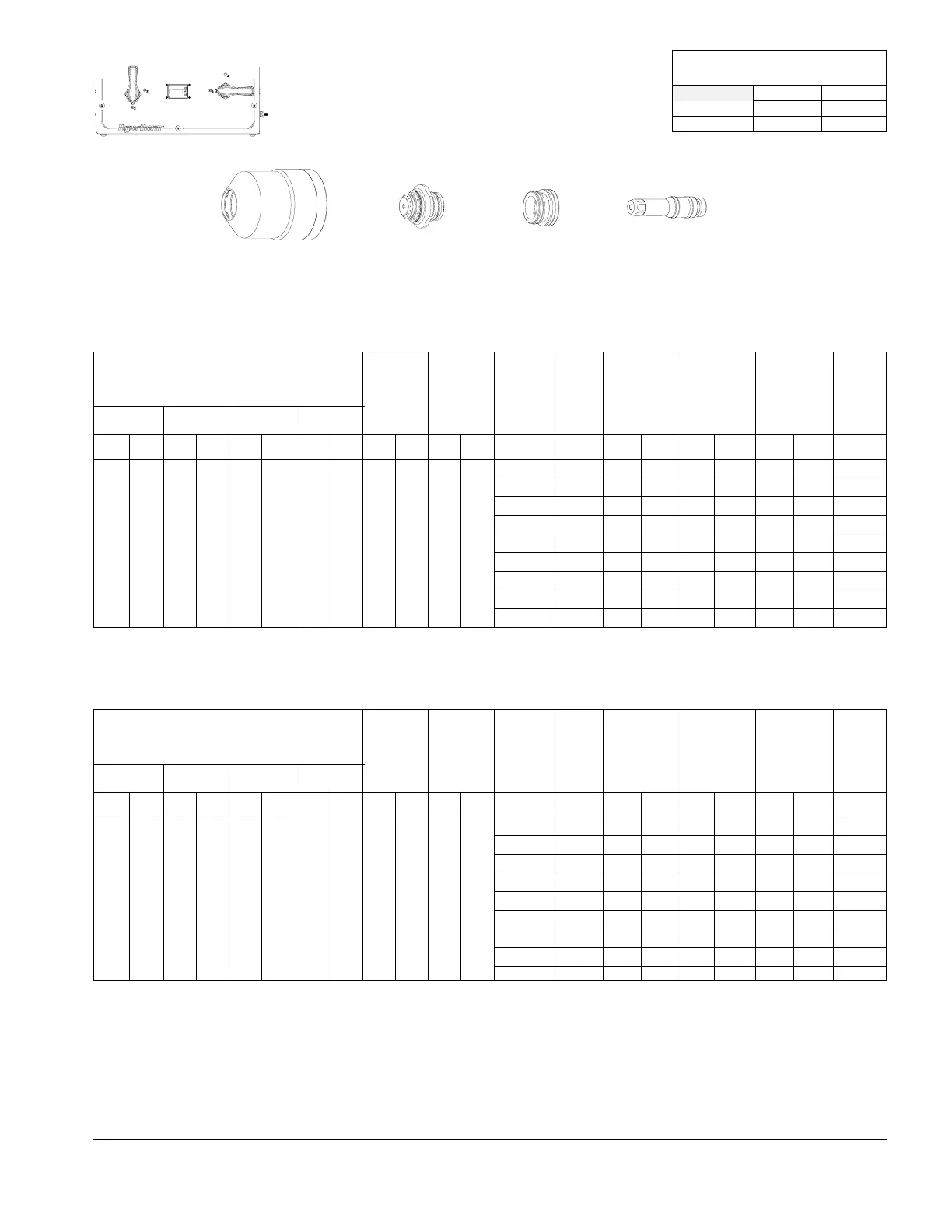

METRIC

Material

Thickness

Plasma PlasmaShield Shield

MV1 MV2 MV3 MV4 MV5 MV6 MV7 PG1 PG2 PG1 PG2 mm Volts mm in. mm/m ipm mm in. seconds

Test

Preflow

Verify

(psi)

Test

Cutflow

Verify

(psi)

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce

Delay

Time

Test Preflow and Cutflow Adjust

(psi)

43 34 30 40 0 5 8 27 45 37 36

Loading...

Loading...