APPENDIX C – BEVEL CUTTING

c-4 HPR260 Manual Gas Instruction Manual

4

Cut charts

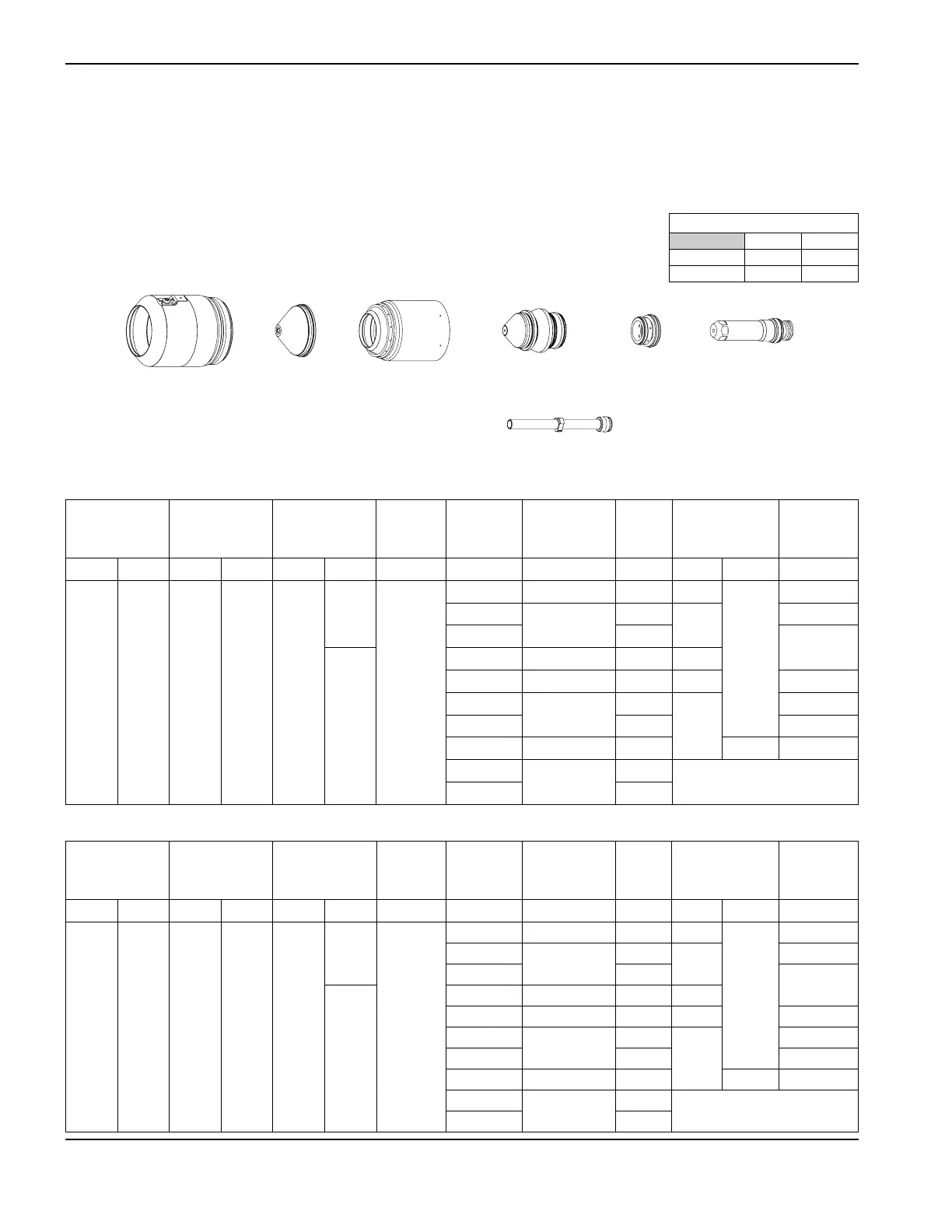

Initial pierce heights and pierce delay times listed in the cut charts are for straight cuts. Edge start indicates that the

material thickness is outside the range that can be pierced. These thicknesses can only be cut by using an edge start.

Mild steel bevel cutting

O

2

Plasma / Air Shield

130 A

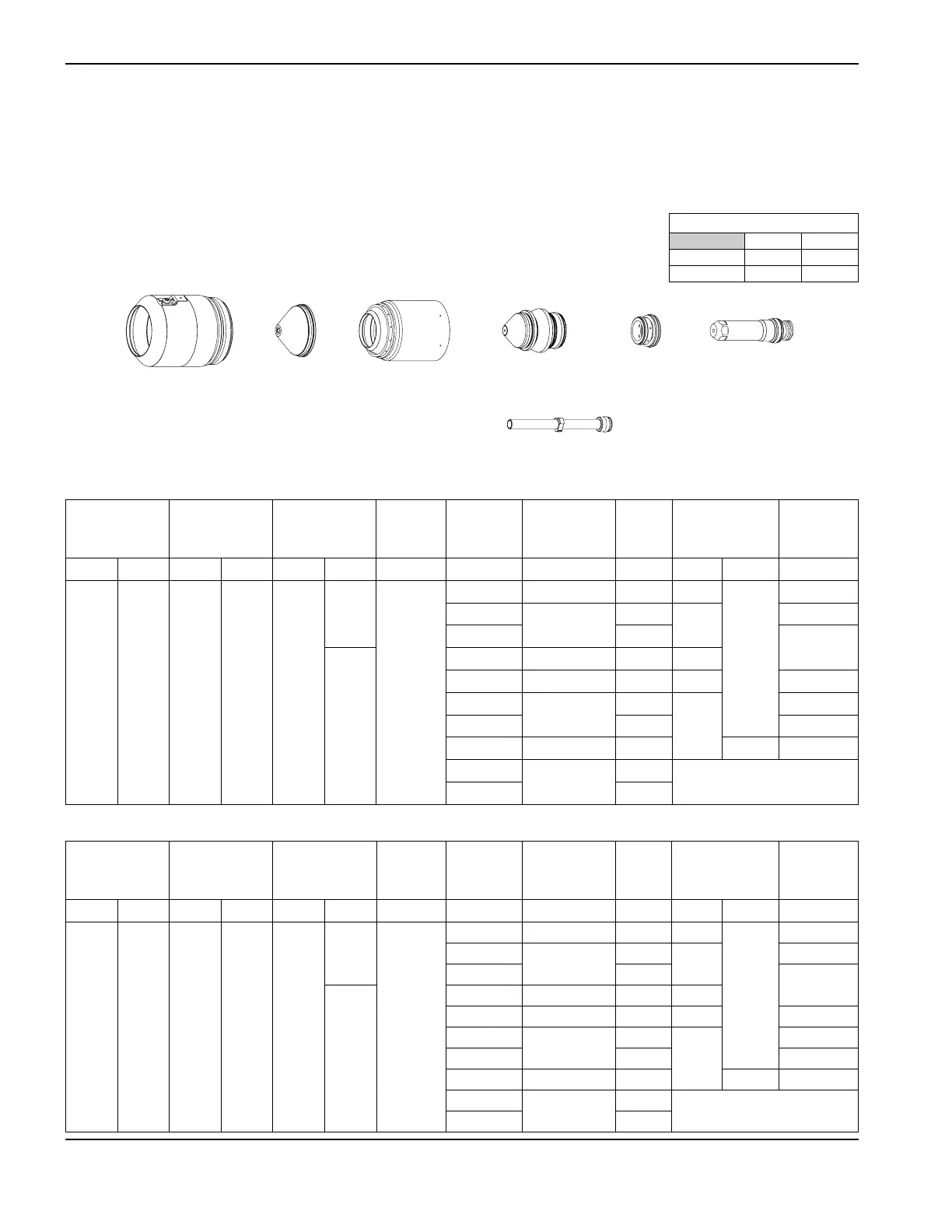

220645220398 220649220603 220179220646

Notes: Bevel angle range is 0° to 45°. Water tube 220700 must be used with these

consumables.

Flow rates – lpm/scfh

O

2

Air

Preflow 0 / 0 64 / 135

Cutflow 33 / 70 45 / 96

Metric

English

Select

Gases

Set

Preflow

Set

Cutflow

Minimum

Clearance

Equivalent

Material

Thickness

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce Delay

Time

Plasma Shield Plasma Shield Plasma Shield mm

mm

mm mm/m mm factor % seconds

O

2

Air 15 23 80

30

2.0

3

2.5 – 8.6 6505 5.0

200

0.1

4

2.8 – 8.6

5550

5.6

0.2

6

4035

0.3

23

10

3.0 – 8.6 2680 6.0

12

3.3 – 8.6 2200 6.6 0.5

15

3.8 – 8.6

1665

7. 6

0.7

20

1050 1.0

25

4.0 – 8.6 550 190 1.8

32

4.5 – 8.6

375

Edge start

38

255

Select

Gases

Set

Preflow

Set

Cutflow

Minimum

Clearance

Equivalent

Material

Thickness

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce Delay

Time

Plasma Shield Plasma Shield Plasma Shield in

in

in ipm in factor % seconds

O

2

Air 15 23 80

30

0.080

0.135

0.100 – 0.340 240 0.200

200

0.1

3/16

0.110 – 0.340

190

0.220

0.2

1/4

150

0.3

23

3/8

0.120 – 0.340 110 0.240

1/2

0.130 – 0.340 80 0.260 0.5

5/8

0.150 – 0.340

60

0.300

0.7

3/4

45 1.0

1

0.160 – 0.340 20 190 1.8

1-1/4

0.180 – 0.340

15

Edge start

1-1/2

10

Loading...

Loading...