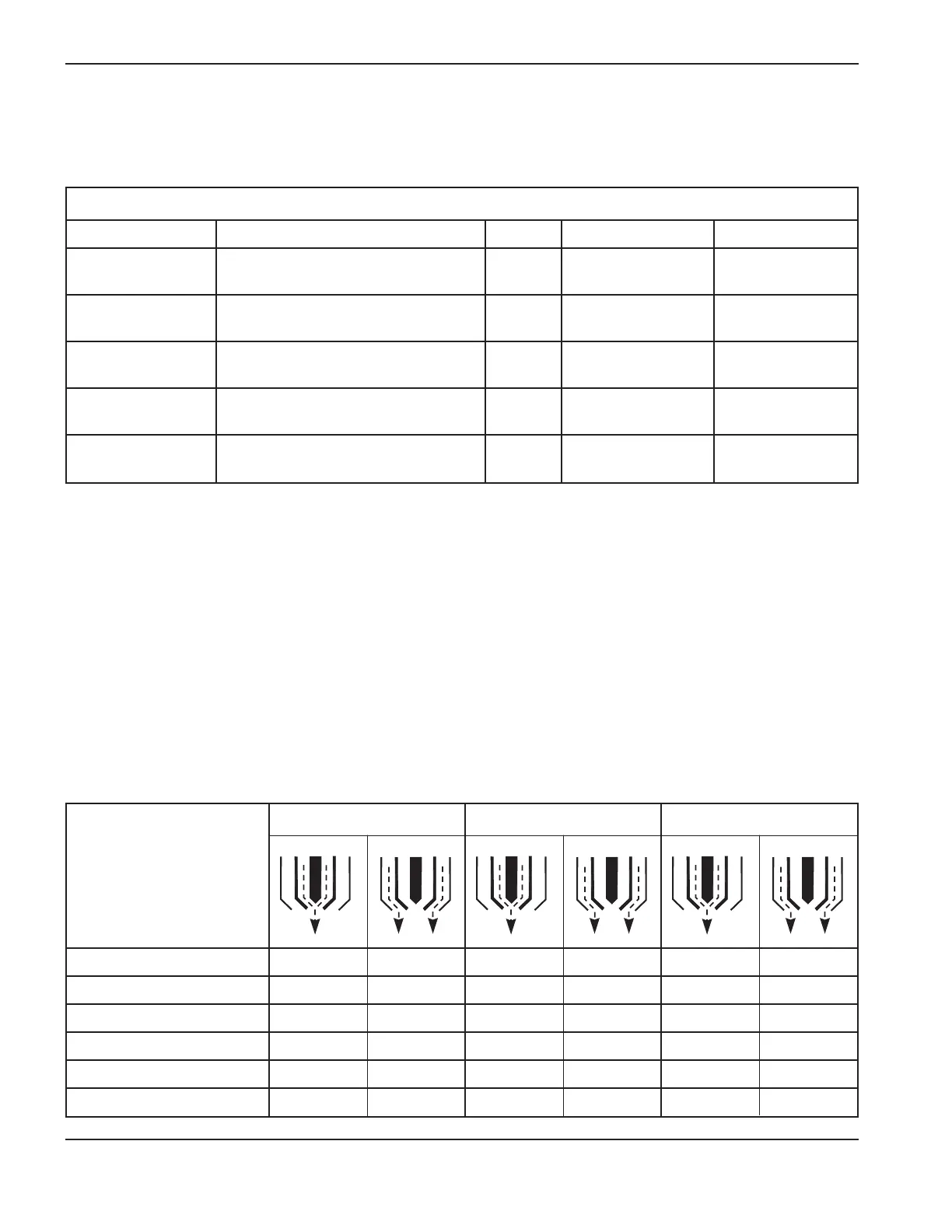

Gas quality and pressure requirements

Quality Grade** Pressure +/- 10% Flow rate

O

2

Oxygen* 99.5% pure G 827 kPa / 8.3 bar 4250 l/h 150 scfh

Clean, dry, oil-free 120 psi

N

2

Nitrogen* 99.99% pure E 827 kPa / 8.3 bar 9910 l/h 350 scfh

Clean, dry, oil-free 120 psi

Air* *** Clean, dry, oil-free per K 827 kPa / 8.3 bar 9910 l/h 350 scfh

ISO 8573-1 Class 1.2.2 120 psi

H35 99.995% pure Ar = A 827 kPa / 8.3 bar 4250 l/h 150 scfh

Argon-hydrogen (H35 = 65% Argon, 35% Hydrogen) H

2

= A 120 psi

F5 99.98% pure N

2

= E 827 kPa / 8.3 bar 4250 l/h 150 scfh

Nitrogen-hydrogen (F5 = 95% Nitrogen, 5% Hydrogen) H

2

= A 120 psi

SPECIFICATIONS

2-4 HPR260 Manual Gas Instruction Manual

6

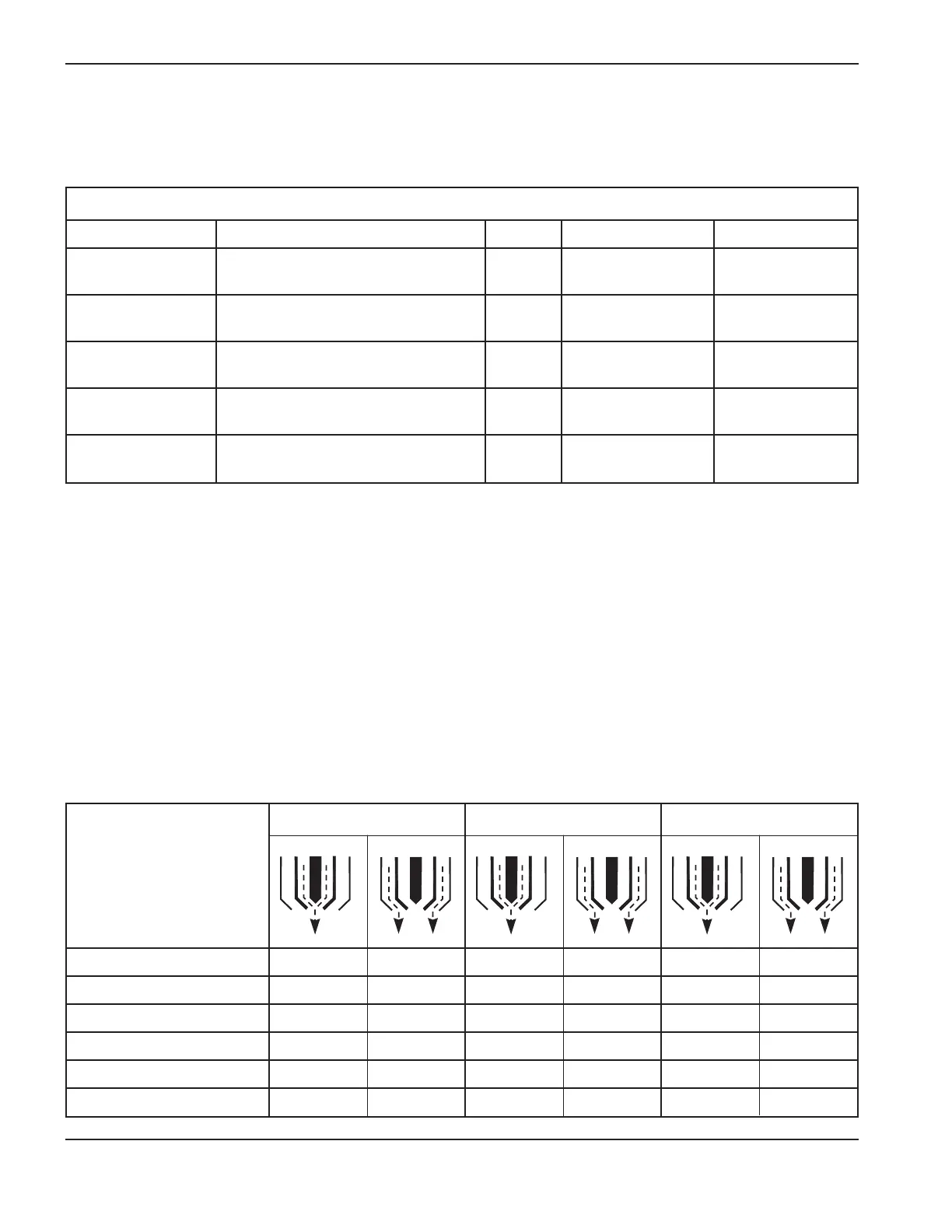

Mild steel Stainless steel Aluminum

Gas types Plasma Shield Plasma Shield Plasma Shield

Cutting 30 to 50 A O

2

O

2

N

2

& F5 N

2

Air Air

Cutting 80 A O

2

Air F5 N

2

Cutting 130 A O

2

Air N

2

& H35 N

2

H35 & Air N

2

& Air

Cutting 200 A O

2

Air N

2

& H35 N

2

N

2

& H35 N

2

Cutting 260 A O

2

Air N

2

& H35 N

2

& Air N

2

& H35 N

2

& Air

Specifications

System gas requirements

* Oxygen, nitrogen, and air are required for all systems. Nitrogen is used as a purge gas.

** This information can be found in the Handbook of Compressed Gases, 3rd edition, Compressed Gas Association,

Van Nostrand Reinhold.

*** ISO standard 8573-1 Class 1.2.2 requirements are:

• Particulates – no more than 100 particles per cubic meter of air at a Size of 0.1 to 0.5 microns in the largest

dimension and 1 particle per cubic meter of air at a Size of 0.5 to 5.0 microns in the largest

dimension.

• Water – there can not be more humidity in the air than in air at –40° C (–40° F).

• Oil – the concentration of oil can be no more than 0.1 mg per cubic meter of air.

Loading...

Loading...