APPENDIX C – BEVEL CUTTING

HPR260 Manual Gas Instruction Manual c-11

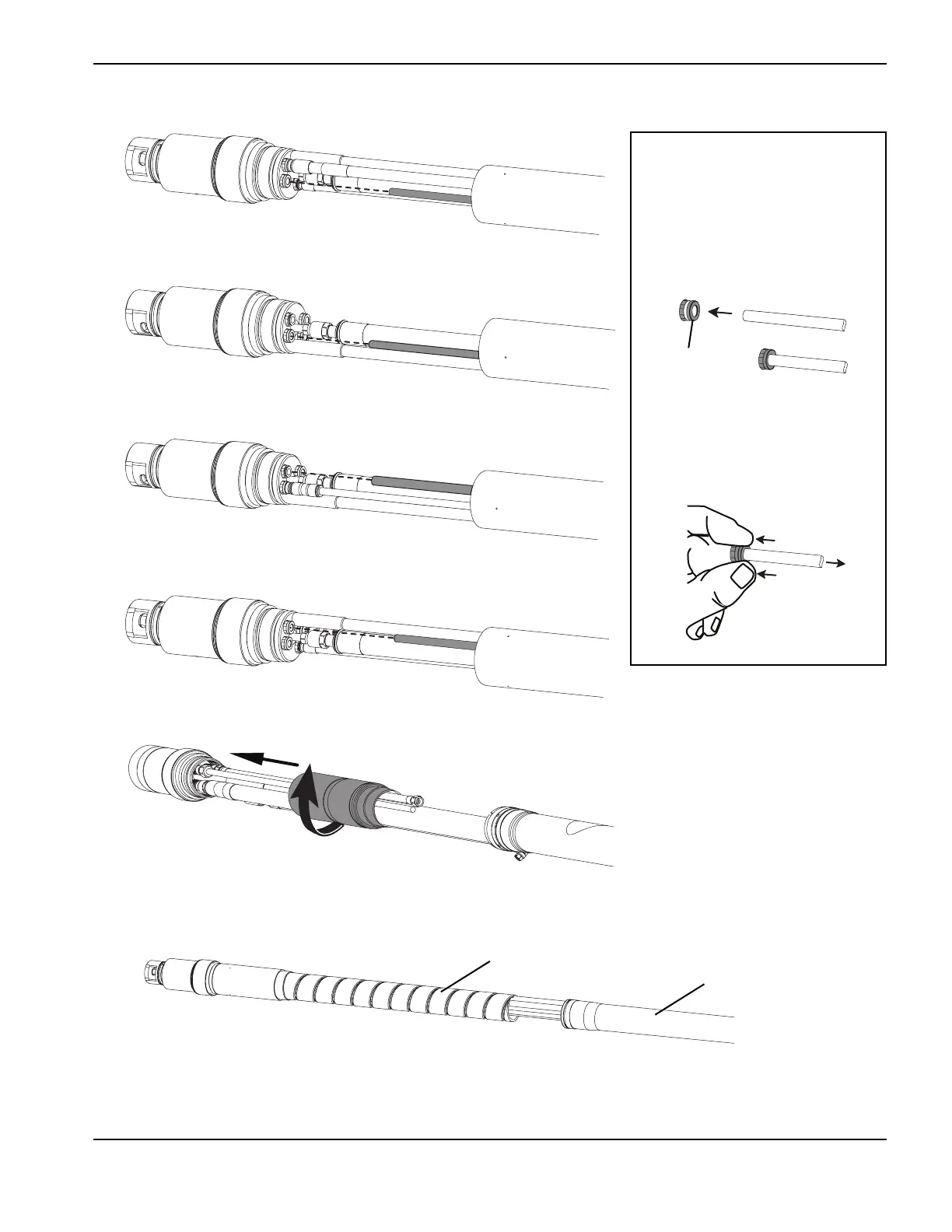

6. Connect the plasma vent hose (white).

7. Connect the coolant return hose (red).

8. Connect the plasma gas hose (black).

9. Connect the shield gas hose (blue).

10. Slide the mounting sleeve over the connections and screw it onto the torch quick-disconnect.

11. Slide the spiral wrap into the torch sleeve, about 50 mm (2 in). There will be a gap between the spiral wrap and the

braided cover. The spiral wrap and braiding do not get clamped in place.

Note: The connectors in steps

6–9 are push-to-connect

fittings.

To make a connection, slide

the hose fitting into the

appropriate connector until it

stops.

To disconnect a fitting, pull

back on the connector-collar

and pull out the hose fitting.

connector-collar

Spiral wrap

Braided cover

4