HyPrecision Predictive waterjet pump Operator Manual 810120 107

5 – Preventive maintenance

Preventive maintenance

1. Put the cylinder on a flat surface.

2. Examine the end of the cylinder. If the area around the bore is marked or pitted, remove the defects with

emery cloth and then with a nonstick scouring pad.

3. Examine the edges of the cylinder bore. If the bore has rough edges or burrs, remove the defects with an

emery cloth.

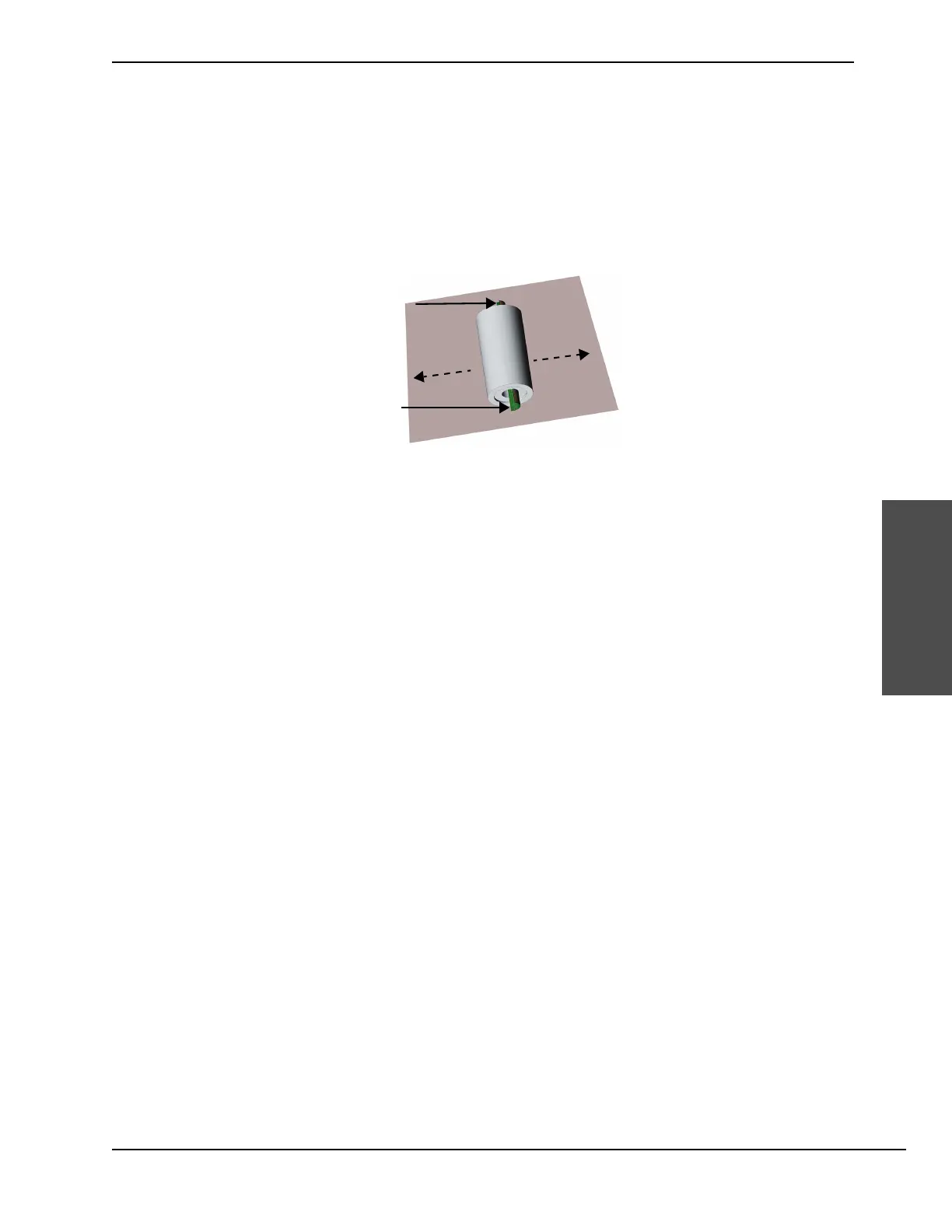

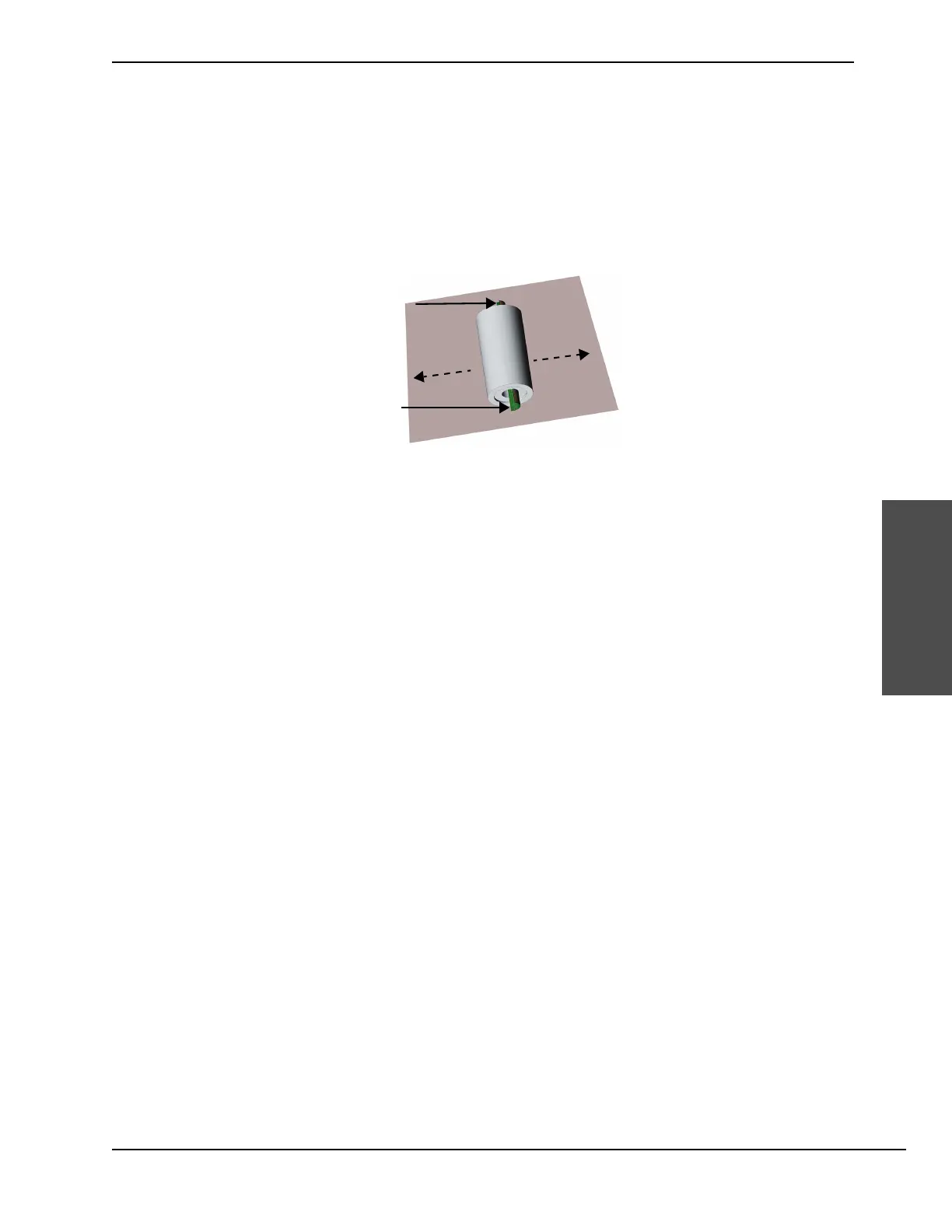

4. Cut the nonstick scouring pad in half. Put half of the pad in each end of the cylinder. Put 1 thumb in each end

of the cylinder on top of the pad and push down. Push evenly on the pad while rolling the cylinder back and

forth.

5. Cut 2 pieces of lapping paper, each approximately 3 cm (1-1/4 inches) wide by 8 cm (3-1/4 inches) long.

6. Put the lapping paper into the ends of the cylinder with the abrasive side touching the cylinder.

7. Do the rolling procedure again with the lapping paper.

8. Clean the inner surfaces of the cylinder with a towel and isopropyl alcohol.

Nonstick scouring pad

Loading...

Loading...