HyPrecision Predictive waterjet pump Operator Manual 810120 77

5 – Preventive maintenance

Preventive maintenance

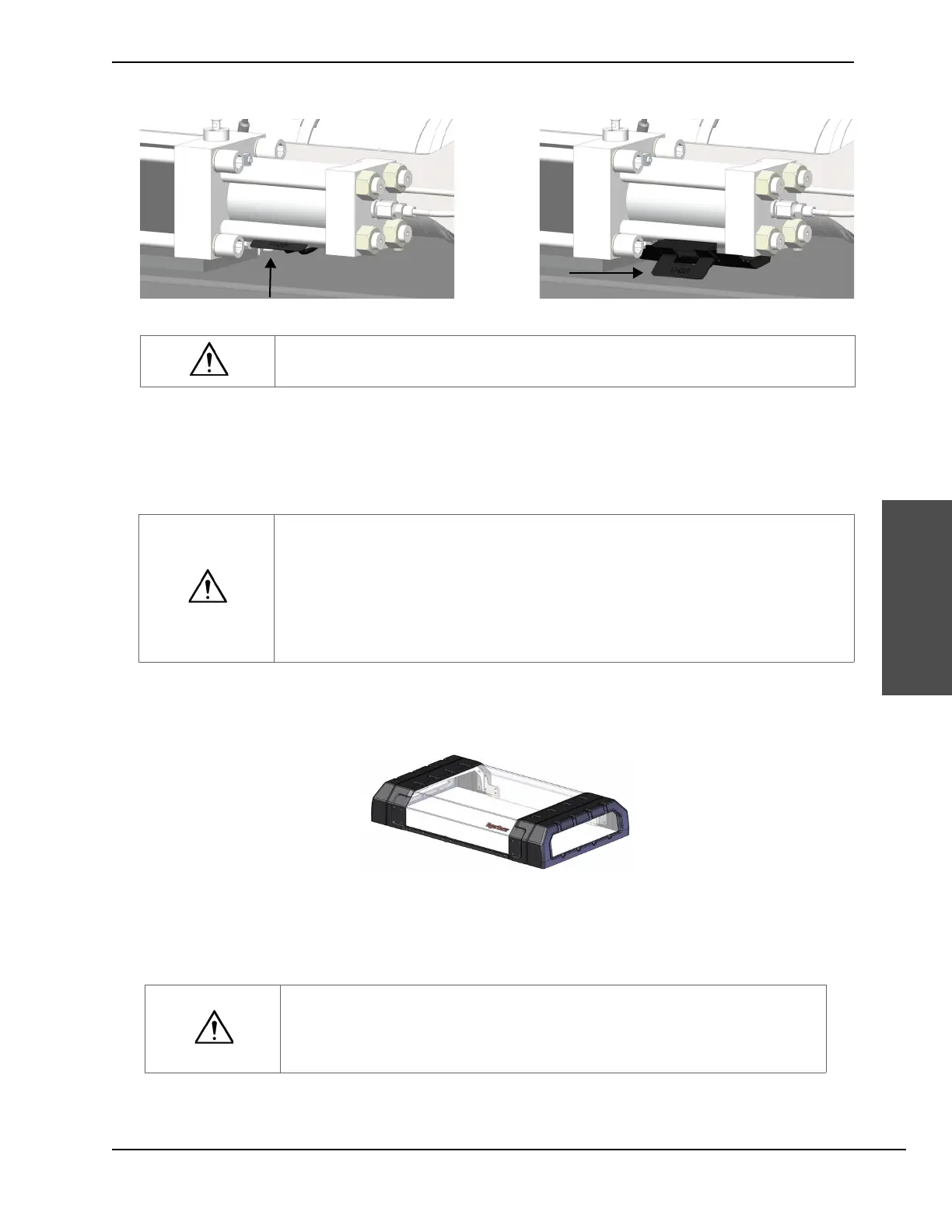

2. Make sure that the drip tray is empty and clean.

To remove the tray, push down on the tab until the tray releases. Pull the tray toward you.

To install the tray, put the rear edge of the tray between the stud and the high-pressure cylinder. Push up on

the tray tab until the tray makes a click.

3. Make sure that all warning decals are visible and legible.

Contact Hypertherm for replacement decals.

4. Clean the operator interface, if necessary.

Gently wipe the touchscreen and keys with a clean microfiber cloth.

Use a cleaner made for touchscreens or use a 1:1 solution of distilled water and white vinegar.

5. Clean the transparent panels on the top cover, if necessary. (For HyPrecision P-50S/P-60S/P-75S pumps)

a. Use a clean microfiber cloth with a cleaner made for acrylic or a solution of clean water and mild dish

soap. Gently dab the surface.

b. After wiping the entire panel, use a dry section of the microfiber cloth to dry and buff the plastic.

c. Do this procedure again until the panel is clean

6. Examine the Seal Maintenance Indicator (SMI) tubes for leaks and debris. To clean the tubes, refer to Clean

the Seal Maintenance Indicator tubes on page 89.

Do not pull the tray out fully. There are 2 tubes attached to the rear of the tray that must be

disconnected first.

To prevent damage to the operator interface:

• Do not use cleaners that contain alcohol, ammonia, acetone, phosphates, or ethylene

glycol.

• Do not push hard on the touchscreen.

• Do not use paper towels, abrasive cloth, or dirty rags.

• Do not put liquid directly onto the touchscreen.

• Do not scratch the surface.

To prevent damage to the transparent panels:

• Do not use cleaners that contain alcohol, ammonia, or acetone.

• Do not use paper towels, abrasive cloth, or dirty rags.

• Do not scratch the surface.

Loading...

Loading...