OPERATION

0

4-12 powermax1000 Operator Manual

Cut Charts

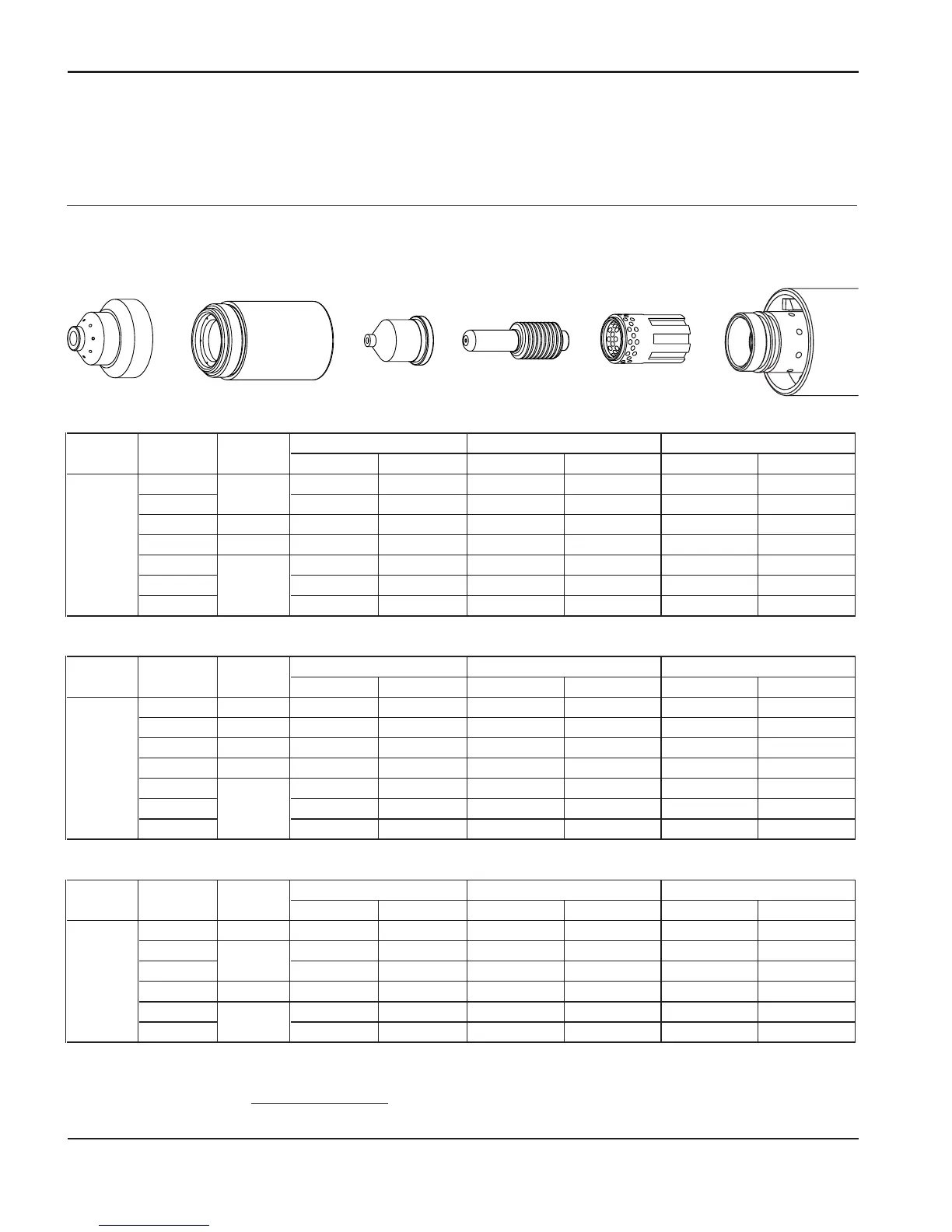

60 Amp Mechanized Shielded Consumables

• Torch-to-work distance for the following cut chart is 1/16 inch (1.5 mm) for all cuts.

Retaining Cap

120928

Nozzle

120931

Electrode

120926

Swirl Ring

120925

T60M

Torch

Shield

120930

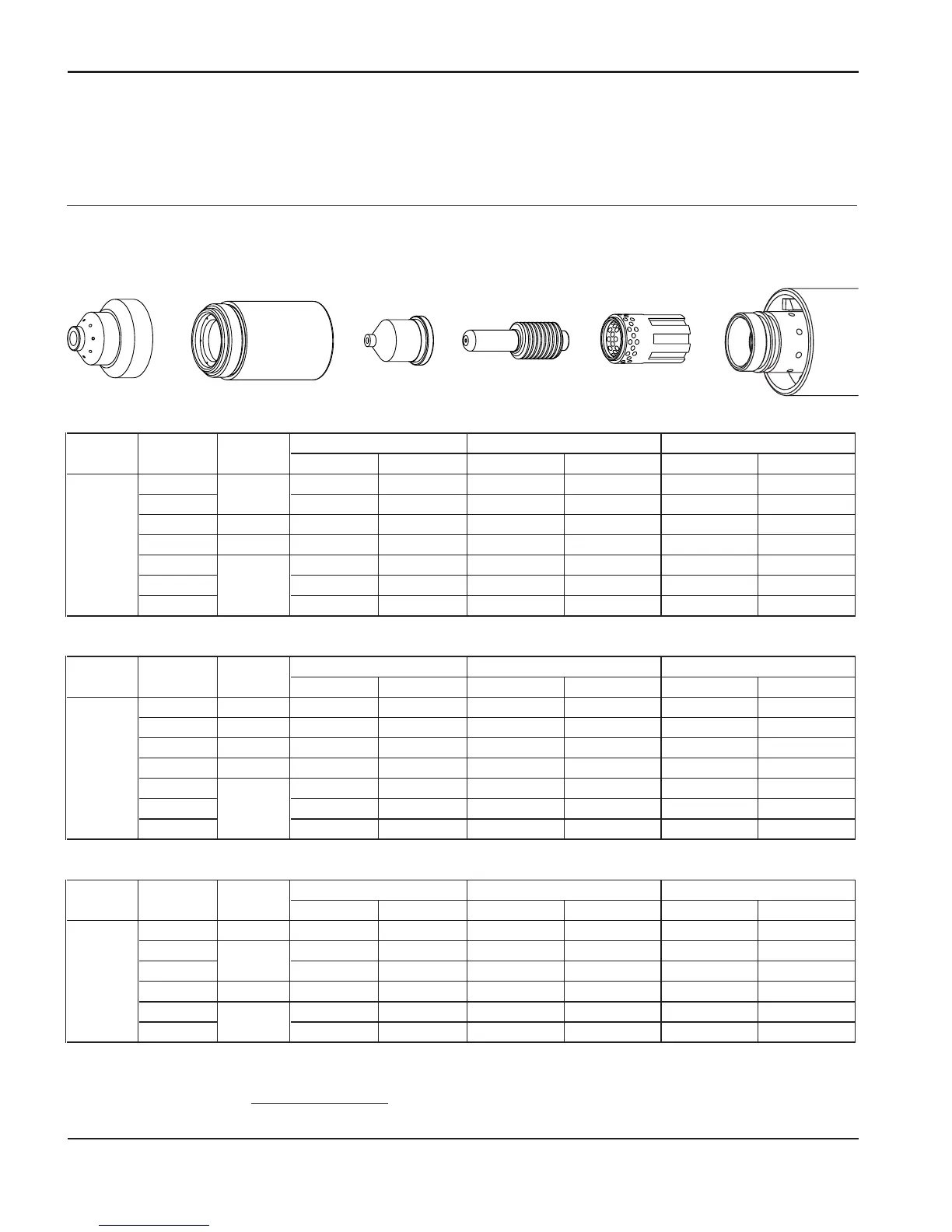

Mild Steel

Inches mm IPM mm/min IPM mm/min

134

16 Ga 1.5 627 15926 502 12751

134 10 Ga 3.4 264

6706

211

5359

138 0.25 1/4" 6.4 132

3353

86

2184

141 0.75 3/8" 9.5 63

1600

41

1041

141 1/2" 12.7 42

1067

27

686

147 5/8" 15.9 31

787

20

512

153 3/4" 19.0 22

559

14

363

Stainless

Inches mm IPM mm/min IPM mm/min

134 0

16 Ga 1.5

625 15875 406 10312

136 0.25 10 Ga 3.4 244 6198 159 4039

139 0.50 1/4" 6.4 110 2794 72 1829

145 0.75 3/8" 9.5 53 1346 34 864

146 1/2" 12.7 35 889 23 584

149 5/8" 15.9 26 660 17 429

154 3/4" 19.0 18 457 12 297

Aluminum

Inches mm IPM mm/min IPM mm/min

135 0 1/16" 1.6 666 16916 433 10995

138 1/8" 3.2 400 10160 260 6604

141 1/4" 6.4 145 3683 94 2388

146 0.75 3/8" 9.5 74 1880 48 1219

149 1/2" 12.7 51 1295 30 762

153 5/8" 15.9 33 838 21 545

Optimum Travel Speeds

Arc

Voltage

Material Thickness

Arc

Current

Maximum Travel Speeds

Arc

Voltage

Pierce

Delay

Material Thickness Maximum Travel Speeds

Pierce

Delay

Arc

Current

Arc

Voltage

Pierce

Delay

Material Thickness Maximum Travel Speeds

Arc

Current

Optimum Travel Speeds

60

60

60

0

1.50

2.00

0.25

1.50

Maximum travel speeds are the fastest travel speeds possible to cut the material without regard to cut quality.

Optimum travel speeds provide the best cut angle, least dross and best cut surface finish. Remember that cut charts

are intended to provide a good starting point

for each different cut assignment. Every cutting system requires

“fine tuning” for each cutting application in order to obtain the desired cut quality.

Loading...

Loading...