OPERATION

0

powermax1000 Operator Manual 4-13

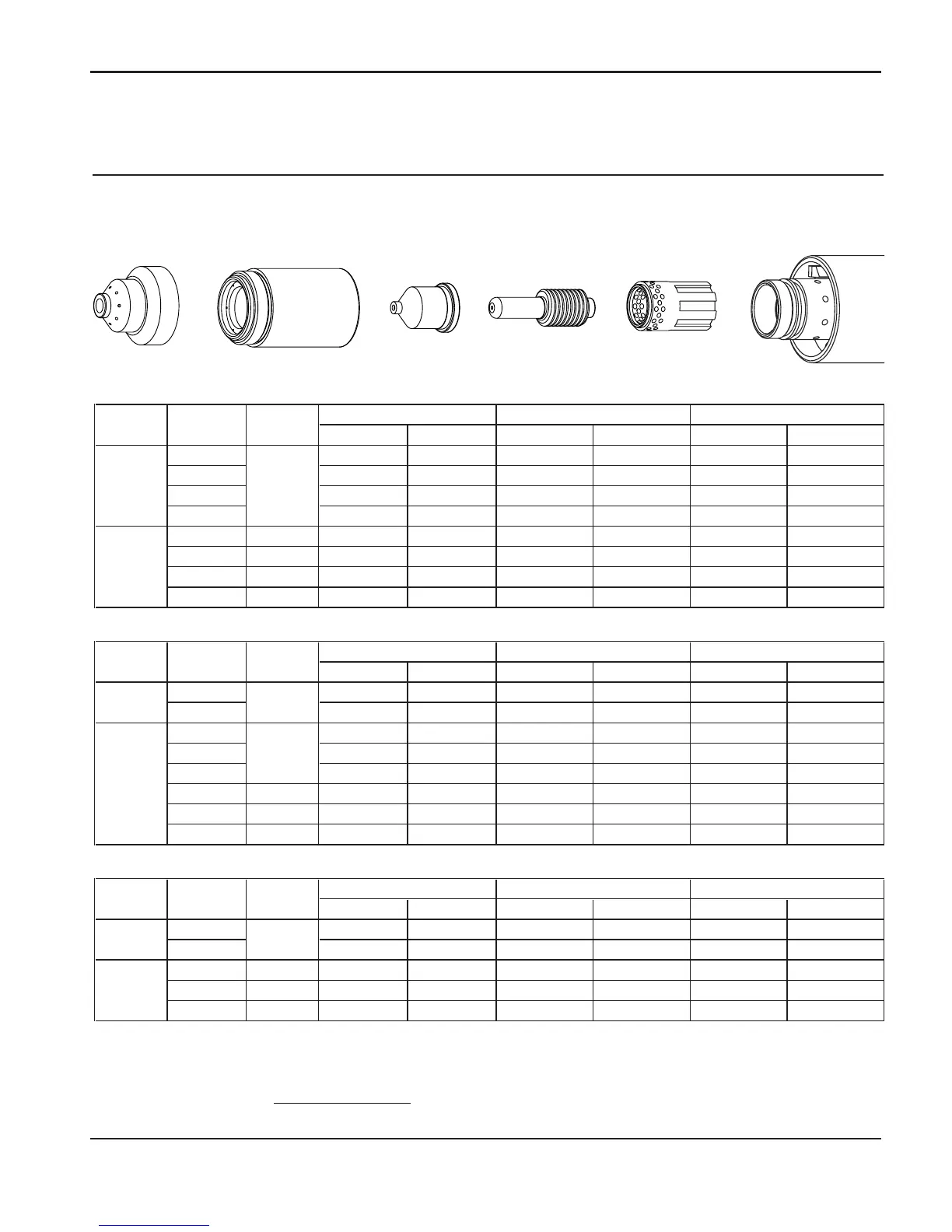

40 Amp Mechanized Shielded Consumables

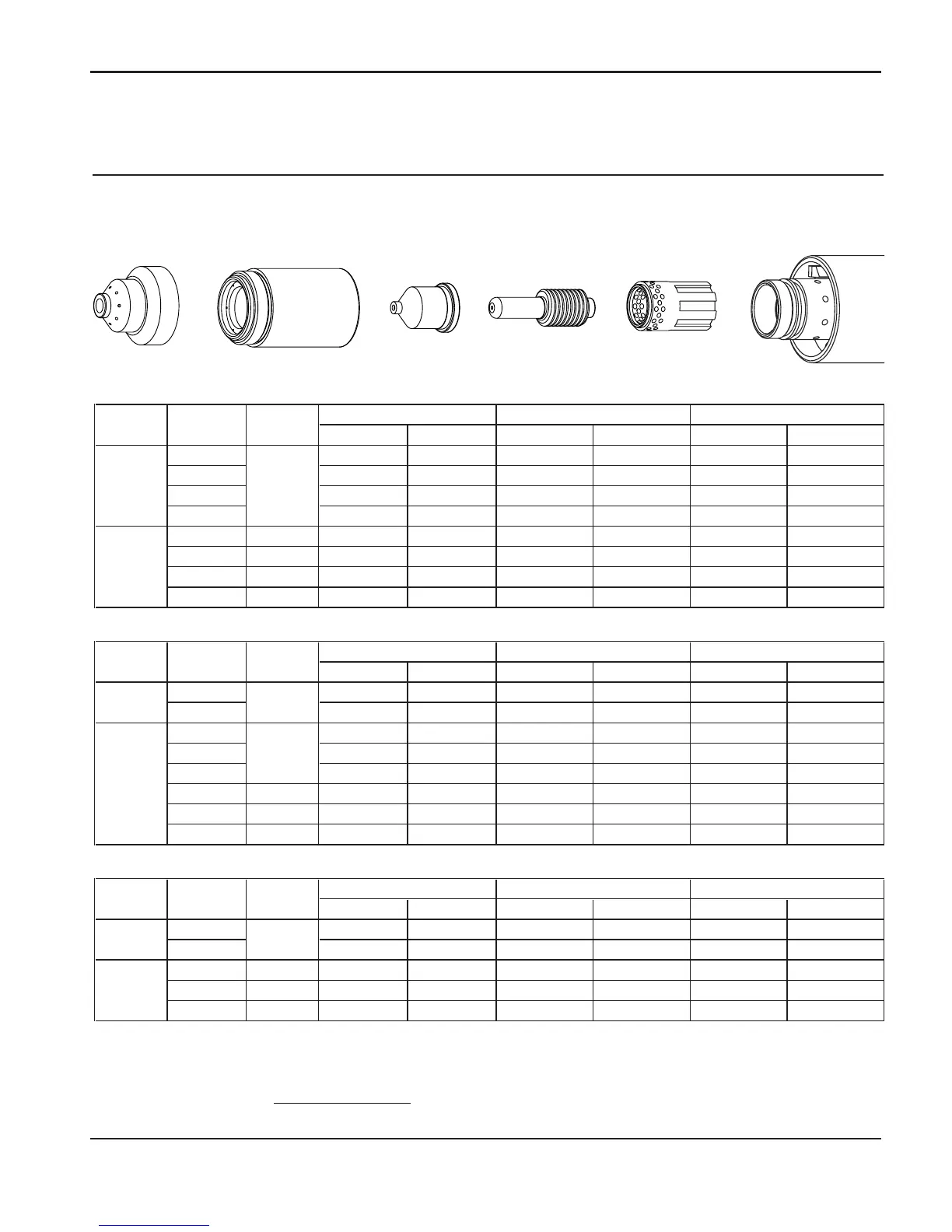

• Torch-to-work distance for the following cut chart is 1/16 inch (1.5 mm) for all cuts.

Retaining Cap

120928

Nozzle

120932

Electrode

120926

Swirl Ring

120925

T60M

Torch

Shield

120930

Mild Steel

Inches mm IPM mm/min IPM mm/min

147 26 GA 0.5 638 16205 415 10541

148 22 GA 0.8 500 12700 325 8255

149 18 GA 1.3 312 7925 203 5156

152 16 GA 1.5 176 4470 114 2896

144 0.25 14 GA 1.9 640 16256 221 5613

146 0.50 10 GA 3.4 151 3835 98 2489

147 0.75 3/16 4.7 97 2464 63 1600

149 1.00 1/4 6.4 74 1880 48 1219

Stainless

Inches mm IPM mm/min IPM mm/min

139 26 GA 0.5 631 16027 410 10414

139 22 GA 0.8 496 12598 322 8179

142 18 GA 1.3 592 15037 335 8509

144 16 GA 1.5 374 9500 243 6172

144 14 GA 1.9 221 5613 144 3658

147 0.50 10 GA 3.4 107 2718 70 1778

149 0.75 3/16 4.7 67 1702 44 1118

149 1.00 1/4 6.4 47 1194 31 787

Aluminum

Inches mm IPM mm/min IPM mm/min

150 1/32 0.8 610 15494 397 10084

152 1/16 1.5 268 6807 174 4420

146 0.25 3/32 2.4 293 7442 190 4826

149 0.50 1/8 3.2 204 5182 133 3378

151 1.00 1/4 6.4 76 1930 49 1245

25

40

0

Optimum Travel Speeds

Optimum Travel Speeds

Arc

Current

Maximum Travel Speeds

Arc

Current

Arc

Voltage

Pierce

Delay

Material Thickness

40

25

Optimum Travel Speeds

Arc

Voltage

Pierce

Delay

Maximum Travel Speeds

0

Material Thickness

Maximum Travel Speeds

25

40

Arc

Current

0.25

0

Arc

Voltage

Pierce

Delay

Material Thickness

Maximum travel speeds are the fastest travel speeds possible to cut the material without regard to cut quality.

Optimum travel speeds provide the best cut angle, least dross and best cut surface finish. Remember that cut charts

are intended to provide a good starting point

for each different cut assignment. Every cutting system requires

“fine tuning” for each cutting application in order to obtain the desired cut quality.

Loading...

Loading...