Maintenance and RepaiR

powermax

65/85

Operator Manual 5-3

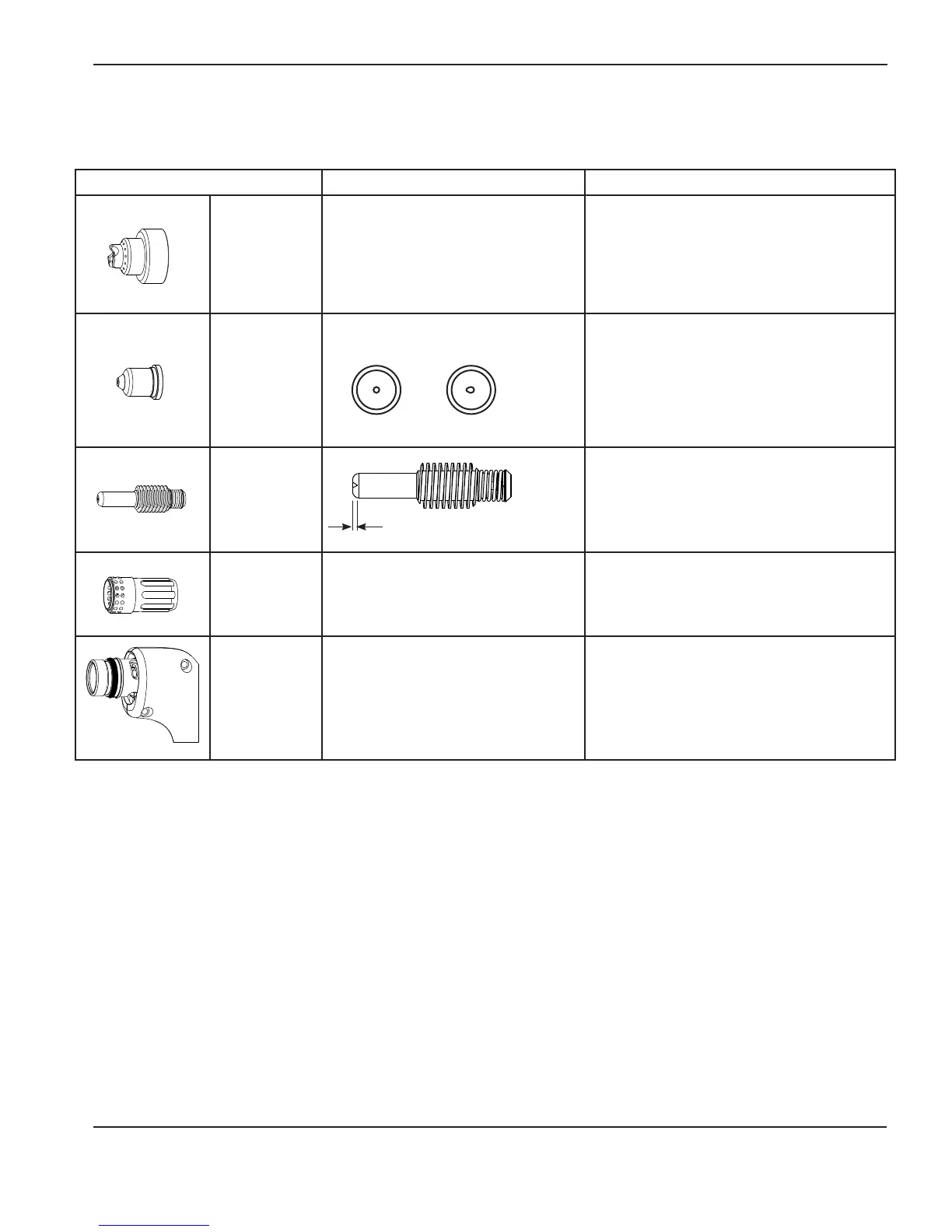

Part Inspect Action

Shield or

deflector

The center hole for roundness.

The gap between the shield and the

nozzle for accumulated debris.

Replace the shield if the hole is no longer

round.

Remove the shield and clean away any

material.

Nozzle The center hole for roundness. Replace nozzle if the center hole is not

round.

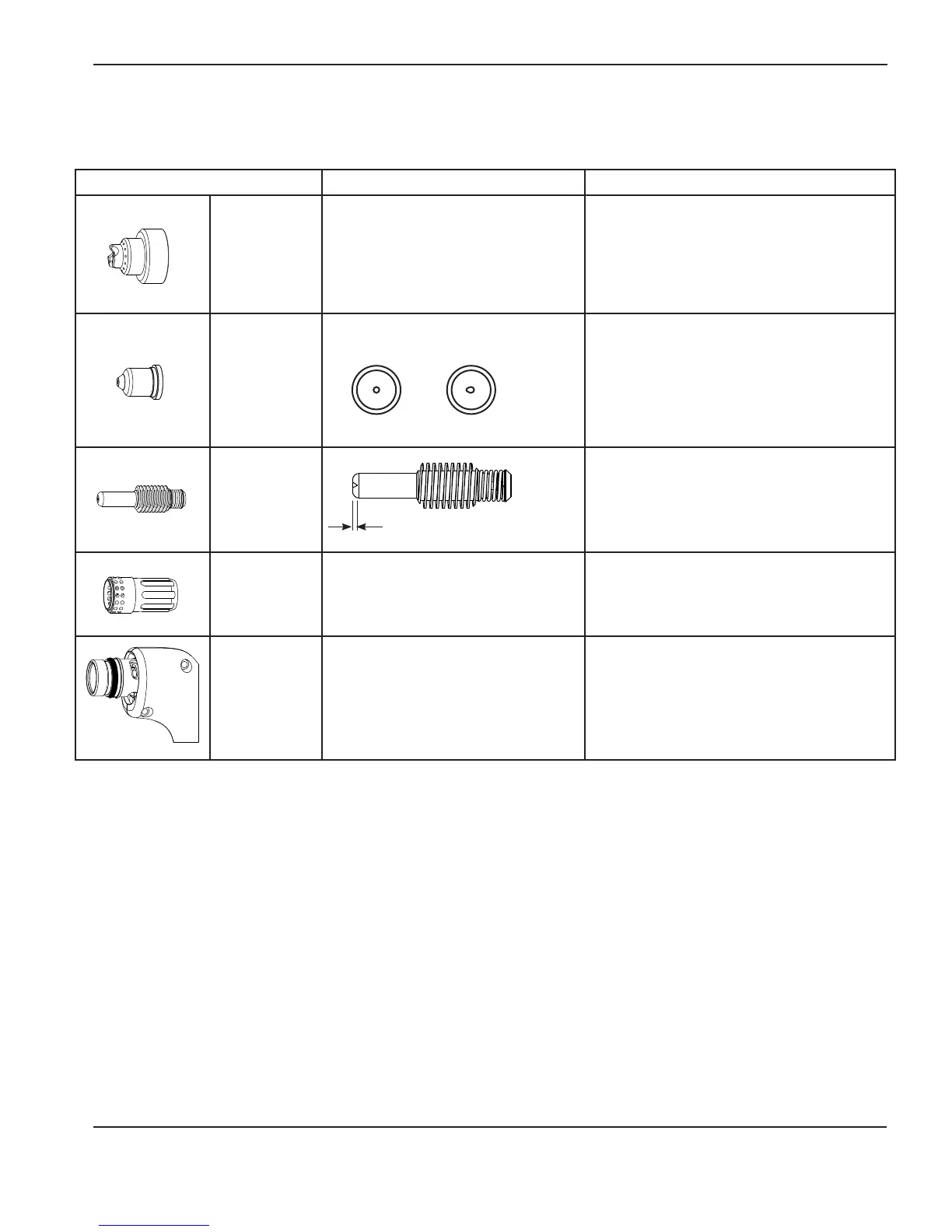

Electrode Replace electrode if the surface is worn

or the pit depth is greater than 1/16 inch

(1.6mm) deep.

Swirl ring The surface inside the swirl ring for

damage or wear and the gas holes

for blockages.

Replace swirl ring if the surface is damaged

or worn or any of the gas holes are blocked.

Torch o-ring The surface for damage, wear, or a

lack of lubrication.

If the o-ring is dry, lubricate it and the

threads with a thin layer of silicone lubricant.

If the o-ring is worn or damaged, replace it.

Max. 1/16 in (1.6 mm)

Good Worn

Inspect the consumables

Loading...

Loading...