MAINTENANCE

3-10

Service Manual

1. Set the Powermax900 power switch to O (off), unplug the power cord, and disconnect the

gas supply.

2. Remove the cover of the power supply by removing the securing screws.

3. Visually inspect the inside of the power supply, especially on the side with the power board

(see Figure 4-3). Look for broken or loose wiring connections, burn and char marks,

damaged components, etc. Repair or replace as necessary.

Resistance Checks

All resistance values in this section were taken with the power cord disconnected, all internal

power supply wires attached, and with the torch unplugged. Perform

Visual Inspection -

Internal

before continuing in this section.

• If your resistance values are not close to the values given in this section, isolate the problem

by removing wires attached to the resistance check points or component until the problem is

found.

• After the problem has been located and repaired, refer to the

Sequence of Operation

flow

diagram in this section to test the power unit for proper operation.

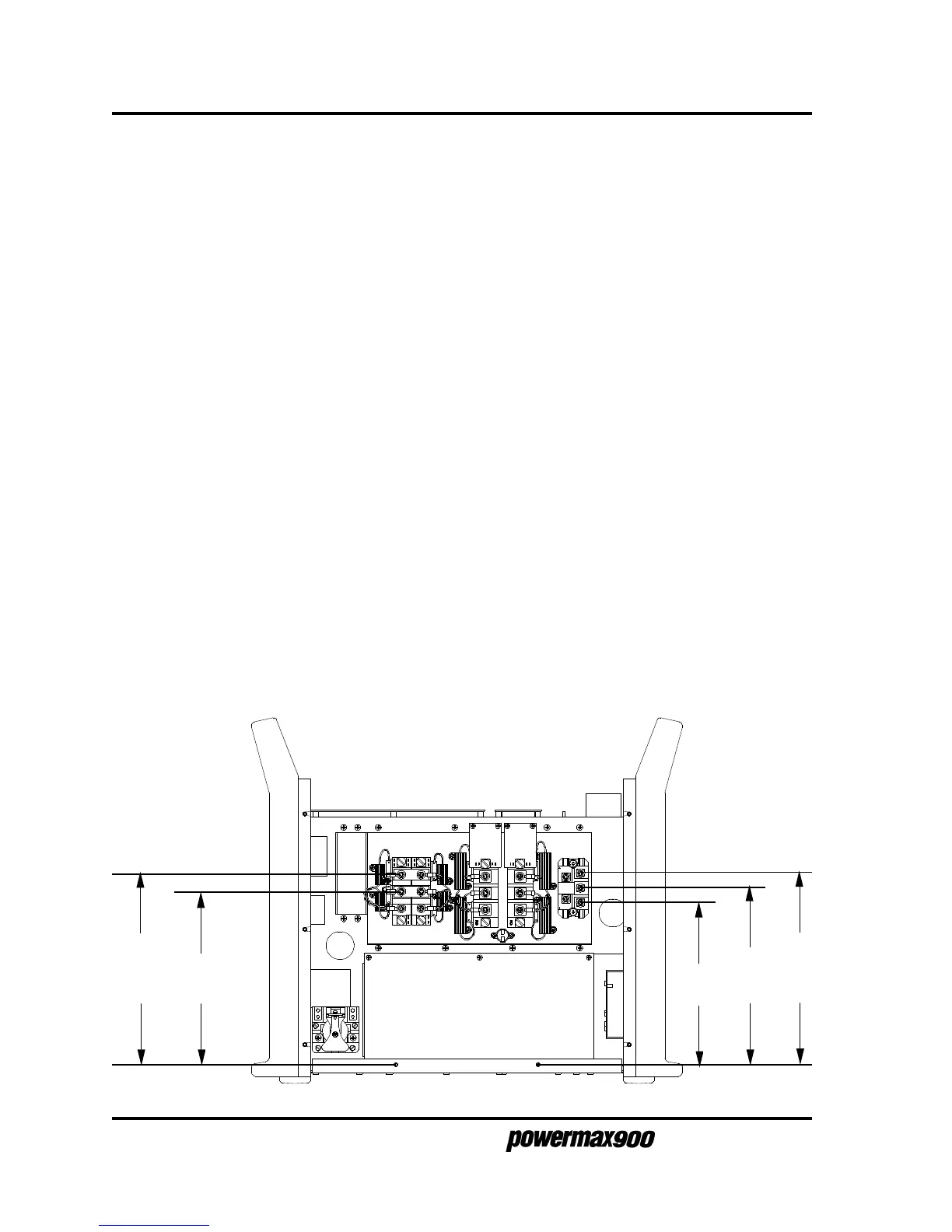

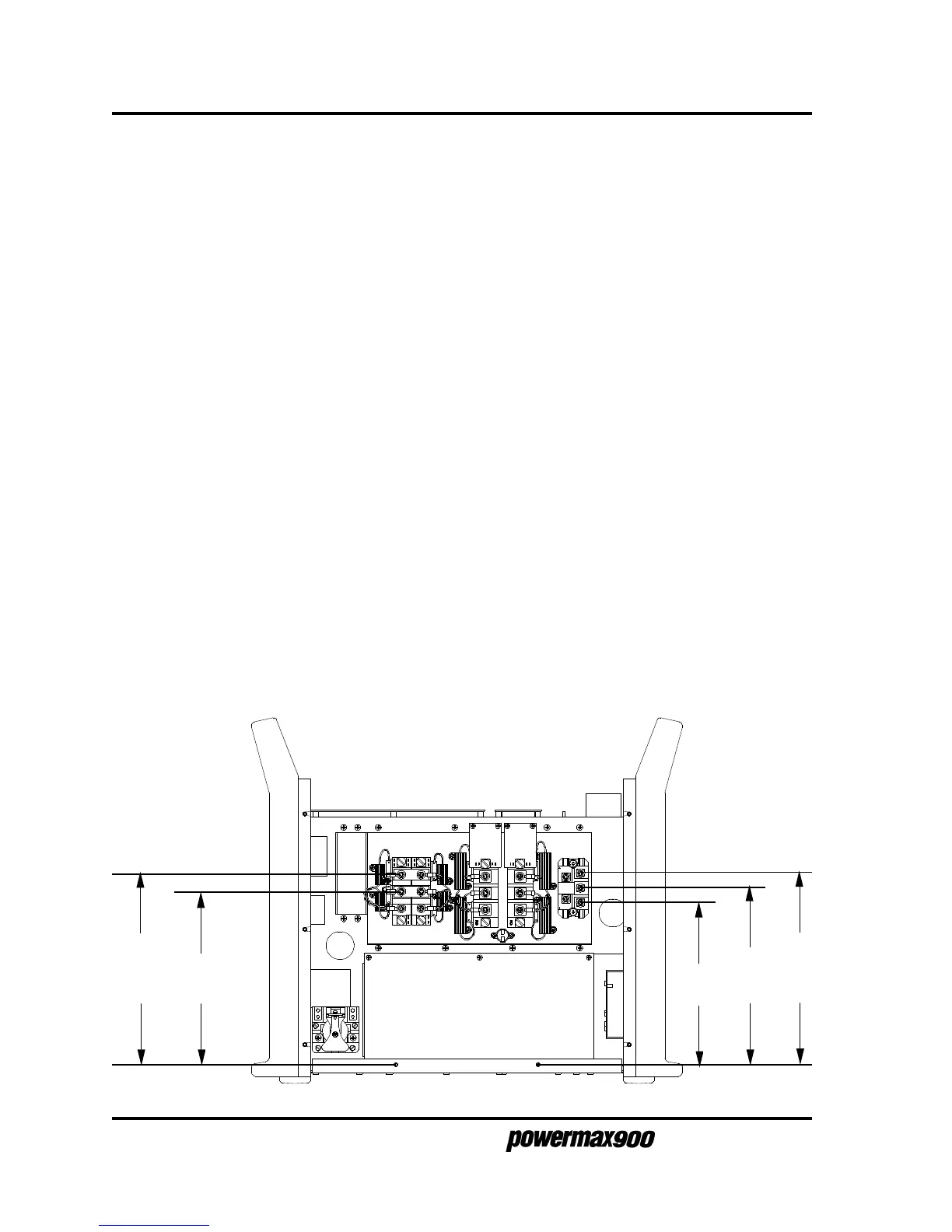

Resistance Check #1 - Fig. 3-8

• Input to Chassis

Inputs to the chassis are open (greater than 50MΩ).

• Output to Chassis

Outputs to the chassis are open (greater than 50MΩ).

> 50MΩ

> 50MΩ

> 50MΩ

> 50MΩ

> 50MΩ

Figure 3-8 Resistance Check #1 - Input to Chassis, Output to Chassis

Loading...

Loading...