3-29

MAINTENANCE

Service Manual

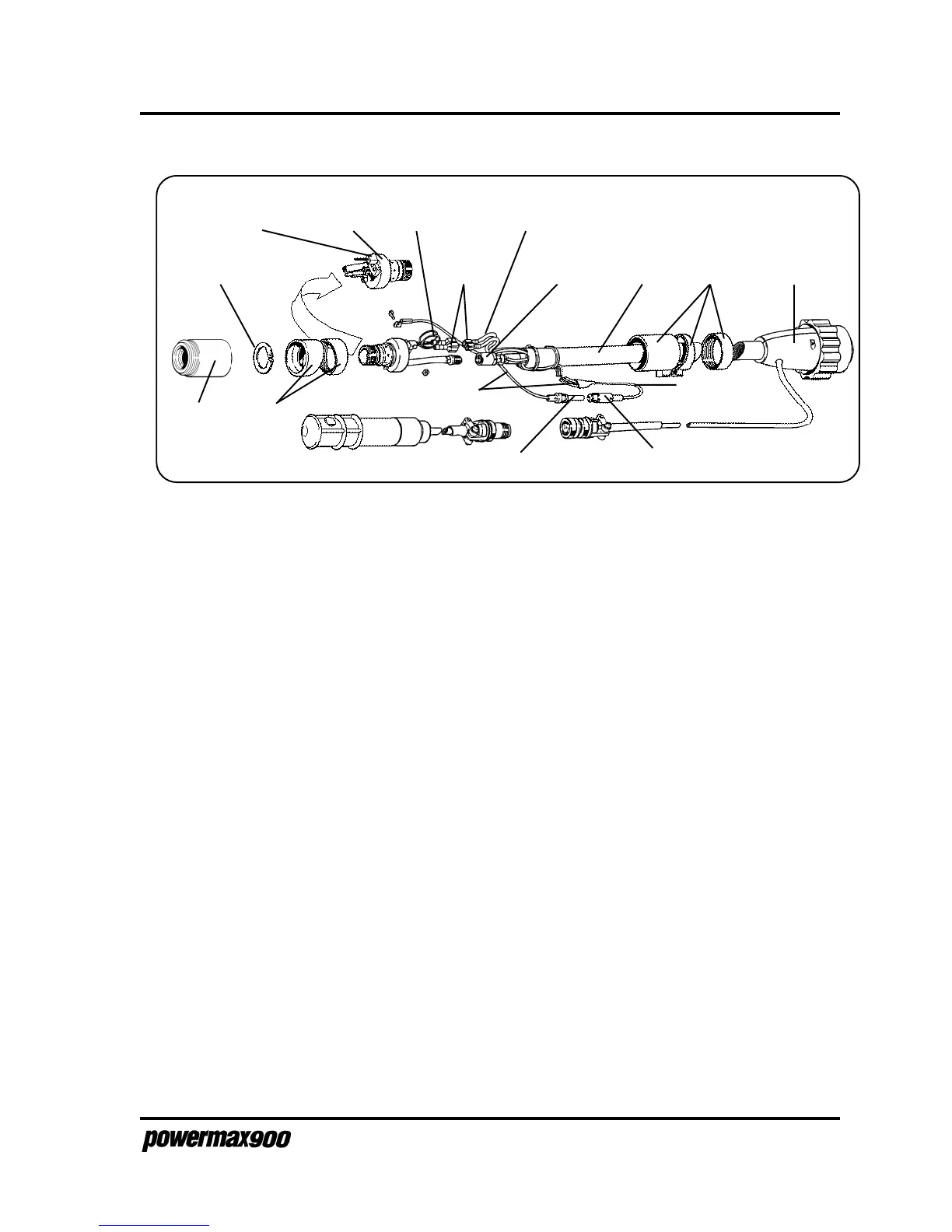

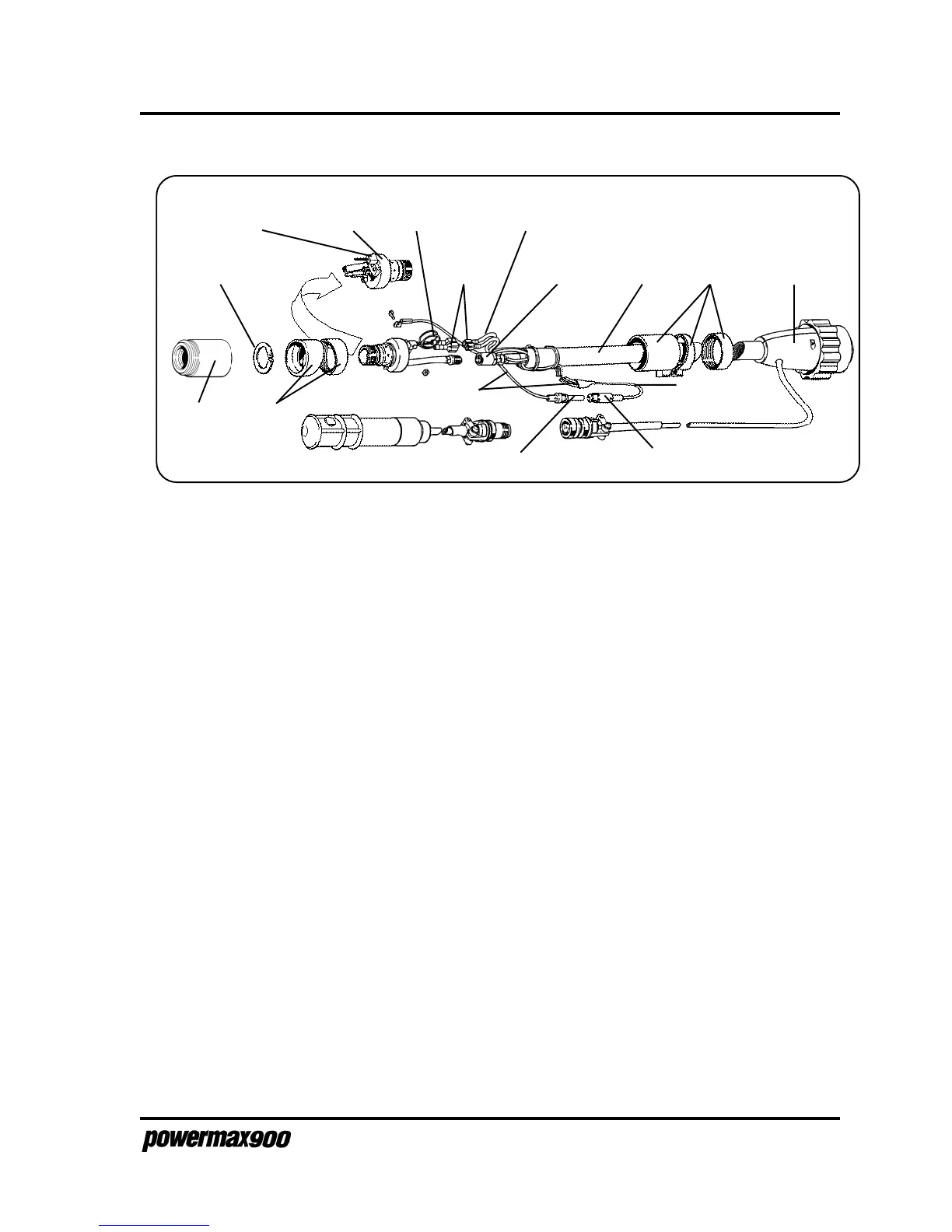

Torch

Lead

Positioning

Sleeve

Blue

Wires (2)

White

Wires (2)

High-Current Wire

Torch

Main Body

Cap Sensor

Microswitch

Torch

Sleeve

Snap Ring

Retaining

Cap

Figure 3-19 PAC125M Torch Assembly

4. Slip 2 small pieces of heat shrink over the cap-sensor microswitch wires and connect the

white wires to the blue wire terminals on the torch lead. Slide the heat shrink over the

terminals and apply heat.

5. Slip a large piece of heat shrink over the high-current wire and connect the pin to the

receptacle. Slide the heat shrink over the pin-receptacle connection and apply heat.

6. Loop the high-current wire next to the torch lead and secure with 2 plastic ties. Be certain

that there is slack between the high-current wire and the torch lead gas fitting.

7. Slide the positioning sleeve back down over the torch lead and screw it into the torch sleeve.

Be certain not to pinch any wires when screwing sleeves together.

8. Install the proper consumables into the torch. When the retaining cap is tightened, the

microswitch will click, indicating that the torch main body has been replaced correctly.

Loop these leads next

to the torch lead when

reassembling

Pin Receptacle

Torch

Lead

Connector

Torch Lead

Gas FittingTerminals

Loading...

Loading...