5. Switch on the gas supply to measure the inlet gas pressure. The gas pressure for

natural gas should be around 7" wc at high fire and 11" wc for propane. If the gas

pressure dips below 3½" wc or exceeds 15" wc, the boiler will shut down. If this

occurs, you will need to reset the gas high or low pressure switch. For instructions,

see Resetting the gas high / low pressure switches on page 77.

6. After completing the inlet gas pressure test, switch off the gas supply.

7.

Remove the inlet gas pressure test fitting and manometer from the inlet gas pressure

test port.

8.

Insert the bolt head and tighten using a 3 mm Allen wrench.

6.3.4 Adjusting the gas valve (EX 400, EX 500)

Danger

Making adjustments to the IBC gas valve without a properly calibrated gas

combustion analyzer and by persons who are not trained and experienced in its use is

forbidden. Failure to use an analyzer can result in an immediate hazard.

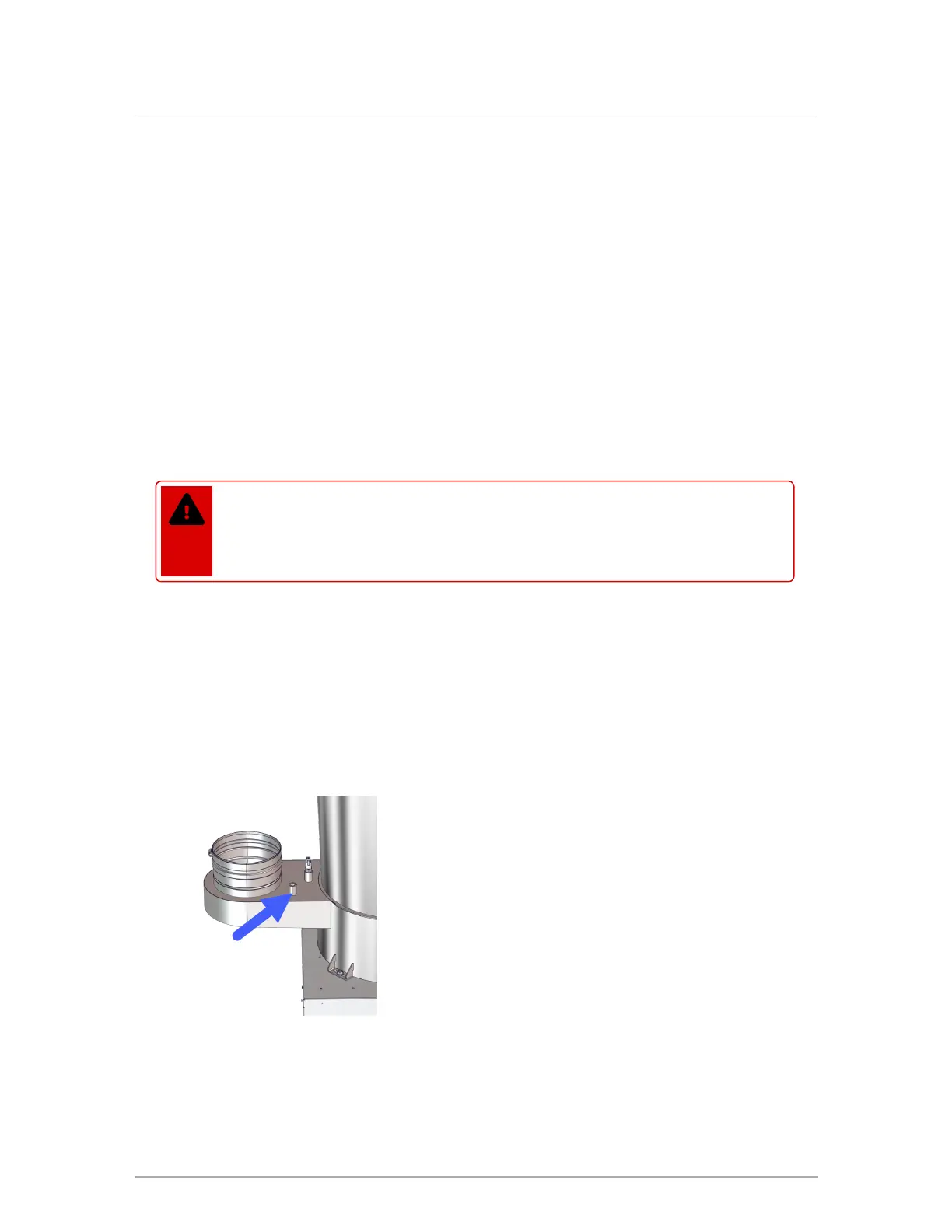

To help with the following procedure, see Figure 42 .

Performing a combustion test

1. Give the boiler a call for heat.

2.

When the boiler reaches high fire, insert the combustion analyzer test probe into the flue

gas test port. Then verify that the CO2 reading is within the combustion test targets at

Table 11 values.

Figure 48 Flue gas test port

Section: Boiler operation

Loading...

Loading...