1-3

INSTALLATION

VFC 15-150 - VFC 45-225 MODULATING GAS BOILERS

contaminants; combustion air should be drawn from a CLEAN source

(e.g. outdoors) and the boiler should be isolated from interior dust

sources. Do not seal boiler case openings directly when ring - allow for

air circulation and ventilation in the immediate area.

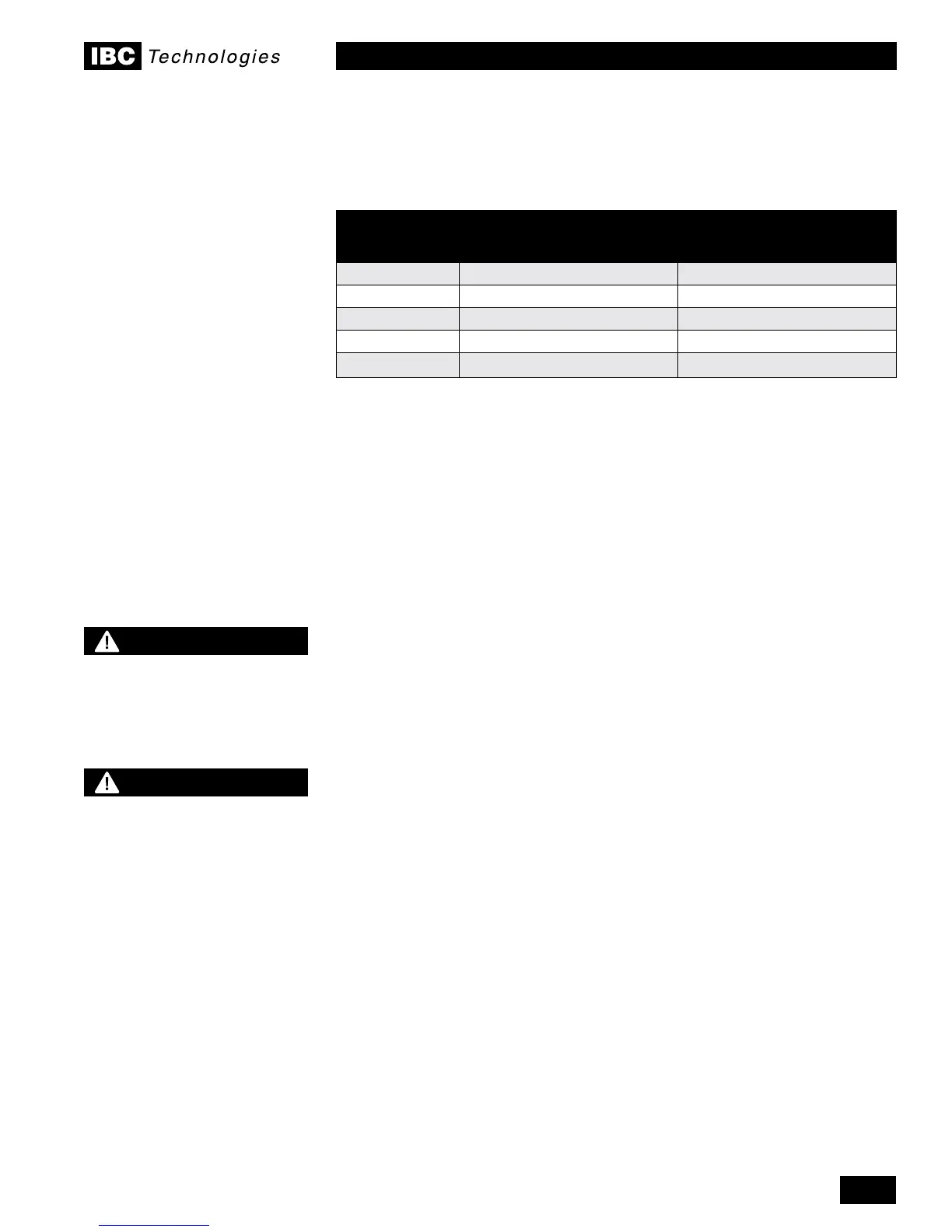

SURFACE

DISTANCE FROM

COMBUSTIBLE

SURFACES

RECOMMENDED

DISTANCE FOR

SERVICE

Front 2" 24"

Rear 0" 0"

Left Side 0" 8" (for vent run)

Right Side 2" 18"

Top 6" 10"

Table 2 - Clearance from boiler cabinet

Distance below the boiler of up to 15" (15-150 model) and up to 24” (45-225

model) is required to provide clearance for the inlet and exhaust venting

together with the required condensation trap. See page 1-15.

EXHAUST VENTING AND AIR INTAKE

It is important to carefully plan the installation to ensure the appropriate

vent materials, travel and termination decisions are incorporated. Specic

attention is warranted to manage the impact of the steam plume normally

experienced at the exhaust terminal of a condensing boiler. Generally,

intake and exhaust pipes should terminate at a rooftop or sterile wall

location, to maximize customer satisfaction. Keep exhaust plumes

well away from all building air intakes including those of neighbouring

properties.

All venting must be installed in accordance with the requirements of the

jurisdiction having authority: in Canada, Part 8, Venting Systems of the B149.1-

10 Code and any other local building codes are to be followed. In the USA

the National Fuel Gas Code, ANSI 223.1, latest edition, prevails. Where there

is a discrepancy between the installation instructions below, and the code

requirements, the more stringent shall apply.

IMPORTANT

When an existing boiler is removed from a common venting system, the common

venting system is likely to be too large for proper venting of the appliances

remaining connected to it.

When resizing any portion of the common venting system, the common venting

system should be resized to approach the minimum size as determined using the

appropriate tables in the National Fuel Gas Code, ANSI Z223.1 - latest edition. In

Canada, use the B149.1-10 Installation Code.

At the time of removal of an existing boiler the following steps shall be followed

with each appliance remaining connected to the common venting system placed

in operation, while the other appliances remaining connected to the common

venting system are not in operation.

1.4

DANGER

Do not common vent the VFC

modulating series boilers

with any other existing or new

appliance.

WARNING

Venting, condensate

drainage, and combustion

air systems for all IBC

boilers must be installed in

compliance with all applicable

codes and the instructions of

their respective Installation

Manuals.

Inspect nished vent and air

piping thoroughly to ensure

all are airtight and comply

with the instructions provided

and with all requirements of

applicable codes.

Failure to comply will result

in severe personal injury or

death.

Loading...

Loading...