2

- Installation & Servicing

GENERAL

CAUTION.

To avoid the possibility of injury during the installation, servicing or cleaning of

this appliance, care should be taken when handling edges of sheet steel components.

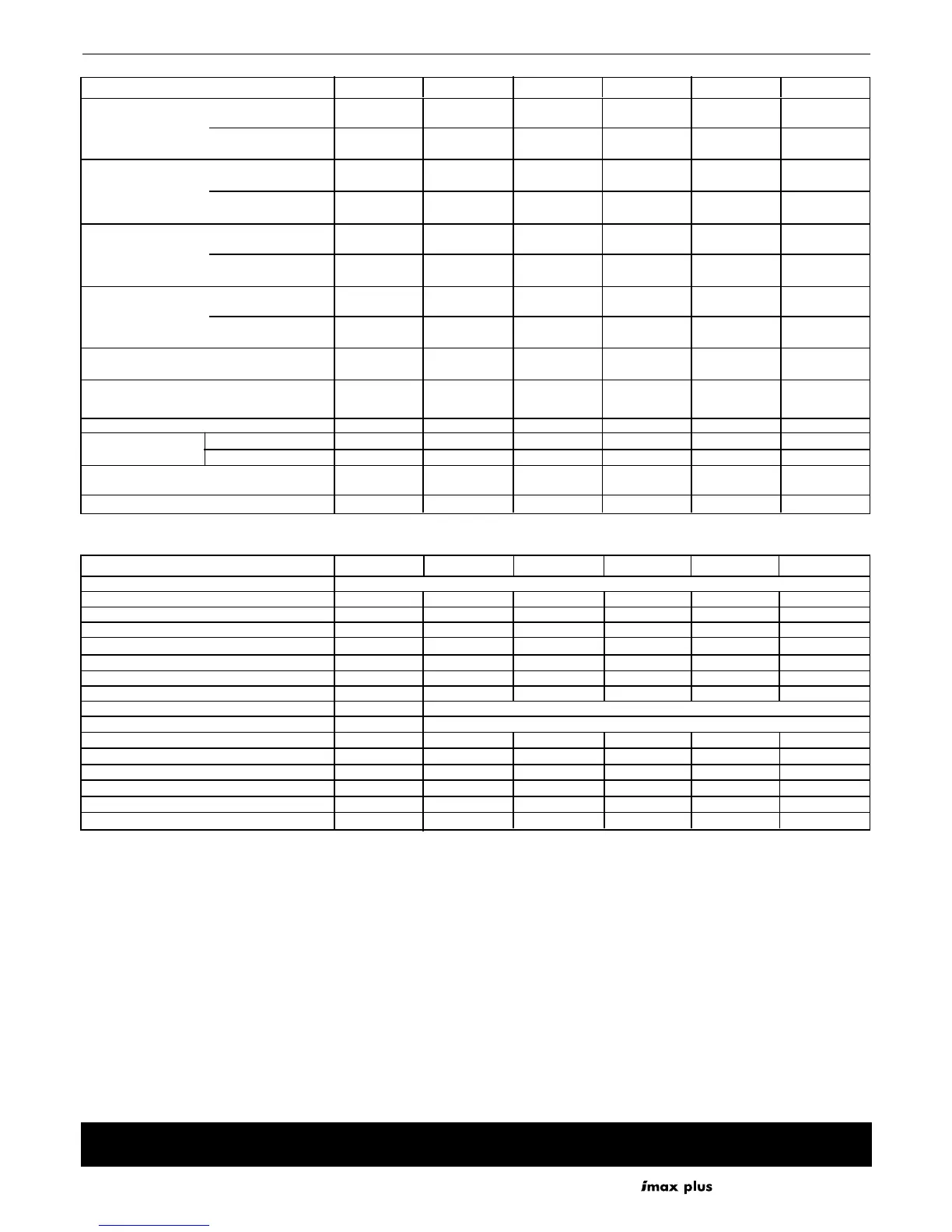

Table 1 Performance Data

Boiler F80 F120 F160 F200 F240 F280

Boiler output Max kW 77.3 116 154.6 193.2 231.8 270.5

(non-condensing) Btu/h 263,750 395,800 545,950 659,250 818,900 923,000

Mean 70ºC Min kW 11.6 11.6 11.6 11.6 11.6 11.6

Btu/h 39,600 39,600 39,600 39,600 39,600 39,600

Boiler output Max kW 83.9 125.9 167.8 209.8 251.8 293.7

(condensing) Btu/h 286,300 429,600 572,550 715,850 859,200 1,002,150

Mean 40ºC Min kW 13.0 13.0 13.0 13.0 13.0 13.0

Btu/h 44,350 44,350 44,350 44,350 44,350 44,350

Boiler Input Nett kW 80 120 160 200 240 280

Max Rate Btu/h 272,950 409,450 545,950 682,450 818,900 955,400

Gross kW 88.8 133.2 177.6 222.0 266.4 310.8

Btu/h 303,000 454,500 606,000 757,500 909,000 1,060,500

Boiler Input Nett kW 12 12 12 12 12 12

Min Rate Btu/h 40,950 40,950 40,950 40,950 40,950 40,950

Gross kW 13.3 13.3 13.3 13.3 13.3 13.3

Btu/h 45,400 45,400 45,400 45,400 45,400 45,400

Maximum Gas Rate m

3

/h 8.42 12.63 16.83 21.04 25.26 29.46

ft

3

/h 297 446 594 743 892 1040

Approx. flue gas @ max. rate m

3

/h 130 196 261 326 392 457

volume (@80ºC) i.e. non-condensing ft

3

/h 4,590 6,920 9,220 11,510 13,840 16,140

Max. Flue Resistance Pa 100 100 100 100 100 100

Flue Gas CO

2

@ Max Rate % 9.0 - 9.2 9.0 - 9.2 9.0 - 9.2 9.0 - 9.2 9.0 - 9.2 9.0 - 9.2

@ Min. Rate % 8.8 - 9.0 8.8 - 9.0 8.8 - 9.0 8.8 - 9.0 8.8 - 9.0 8.8 - 9.0

NOx with O

2

= 0% mg/kWh <62 <62 <62 <62 <62 <62

ppm <35 <35 <35 <35 <35 <35

Part load efficiency (Gross) % 97.7 97.7 97.7 97.7 97.7 97.7

Note.

Natural gas consumption is calculated using a calorific value of

37.8MJ/m

3

(1038Btu/ft

3

) gross or 34 MJ/m

3

(910 Btu/ft

3

) nett at

15ºC and 1013.25 mbar.

a

. For l/s divide the gross heat input (kW) by the gross C.V. of

the gas (MJ/m

3

)

b. For ft/h

3

divide the gross heat input (Btu/h) by the gross C.V.

of the gas (Btu/ft

3

).

HEALTH & SAFETY DOCUMENT NO. 635

The electricity at work regulations, 1989. The manufacturer's

notes must NOT be taken, in any way, as overriding statutory

obligations.

IMPORTANT. These appliances are CE certified for safety and

performance. It is, therefore, important that no external control

devices, e.g. flue dampers, economisers etc., are directly

connected to these appliances unless covered by these

Installation and Servicing Instructions or as otherwise

recommended by Caradon Ideal Limited in writing. If in doubt

please enquire.

Any direct connection of a control device not approved by

Caradon Ideal Limited could invalidate the certification and the

normal appliance warranty. It could also infringe the Gas Safety

Regulations and the above regulations.

* Electricity supply and Fuse rating for pumps etc. refer to manufacturer's instructions.

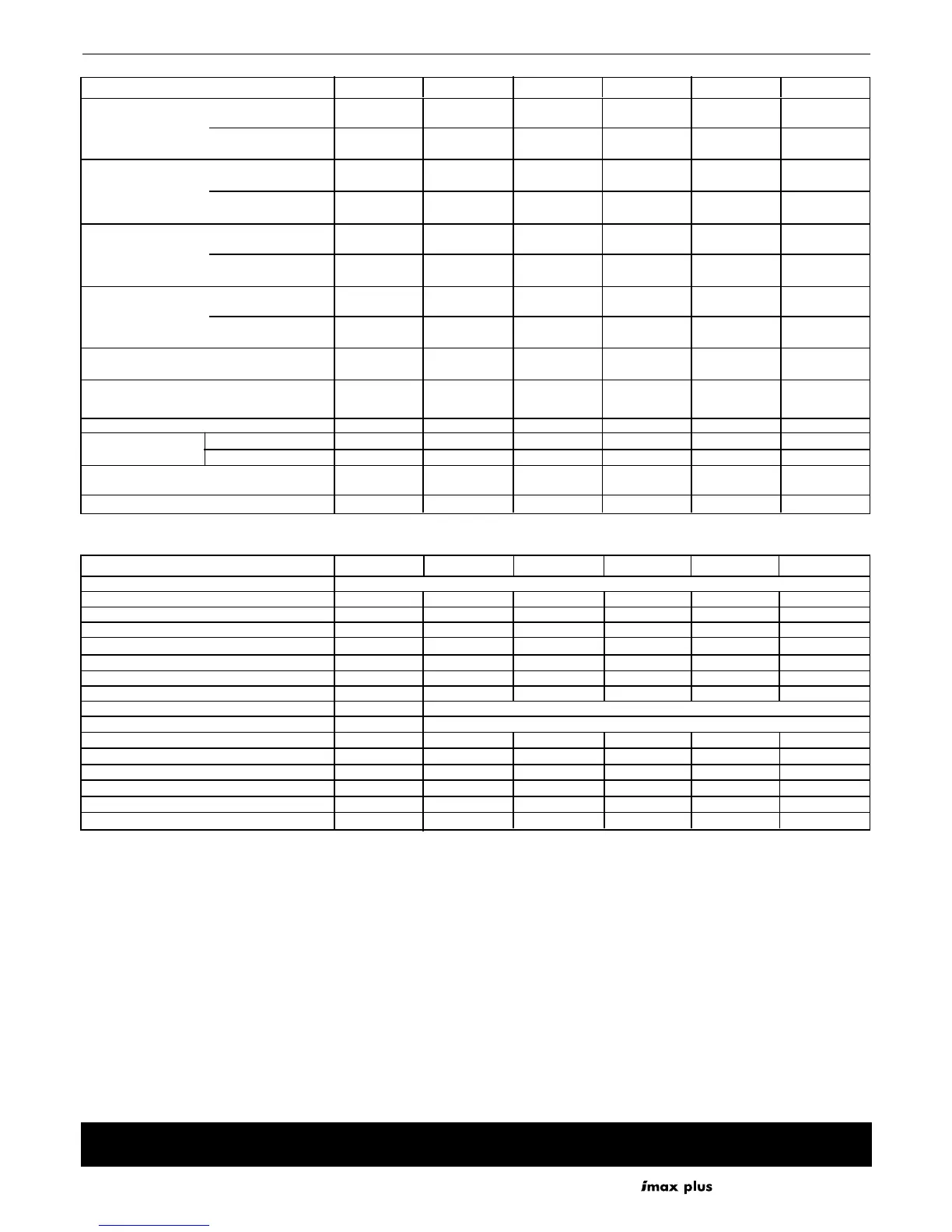

Table 2 General Data

Boiler F80 F120 F160 F200 F240 F280

Gas supply 2H - G20 - 20 mbar

Gas supply connection R (in. BSP) 1

1

/2 1

1

/2 1

1

/2 1

1

/2 1

1

/2 1

1

/2

Flow connection R (in. BSP) 2 2 2 2 2 2

Return connection R (in. BSP) 2 2 2 2 2 2

Hydraulic Resistance @ 11Cº mbar 280 350 450 550 720 870

Hydraulic Resistance @ 20Cº mbar 80 100 130 180 225 275

Max Press (sealed system) bar (psi) 6 (87) 6 (87) 6 (87) 6 (87) 6 (87) 6 (87)

Maximum Static Head m (ft) 61 (200) 61 (200) 61 (200) 61 (200) 61 (200) 61 (200)

Boiler Electricity Supply 230V - 50Hz

Boiler Fuse Rating External: 3A* internal: 1.6AT & 2AF

Power Consumption (boiler only) W 175 250 325 400 475 550

Air Inlet mm 150 150 150 150 150 150

Flue Size dia mm 150 150 150 200 200 200

Condensate drain mm 40 40 40 40 40 40

Water Content l (gal) 10.1 (2.2) 14.2 (3.1) 18.3 (4.0) 22.4 (4.9) 26.5 (5.8) 30.6 (6.7)

Boiler dry weight (unpacked) kg (lb) 153 (337) 182 (401) 223 (492) 261 (575) 301 (664) 345 (761)

Loading...

Loading...