31

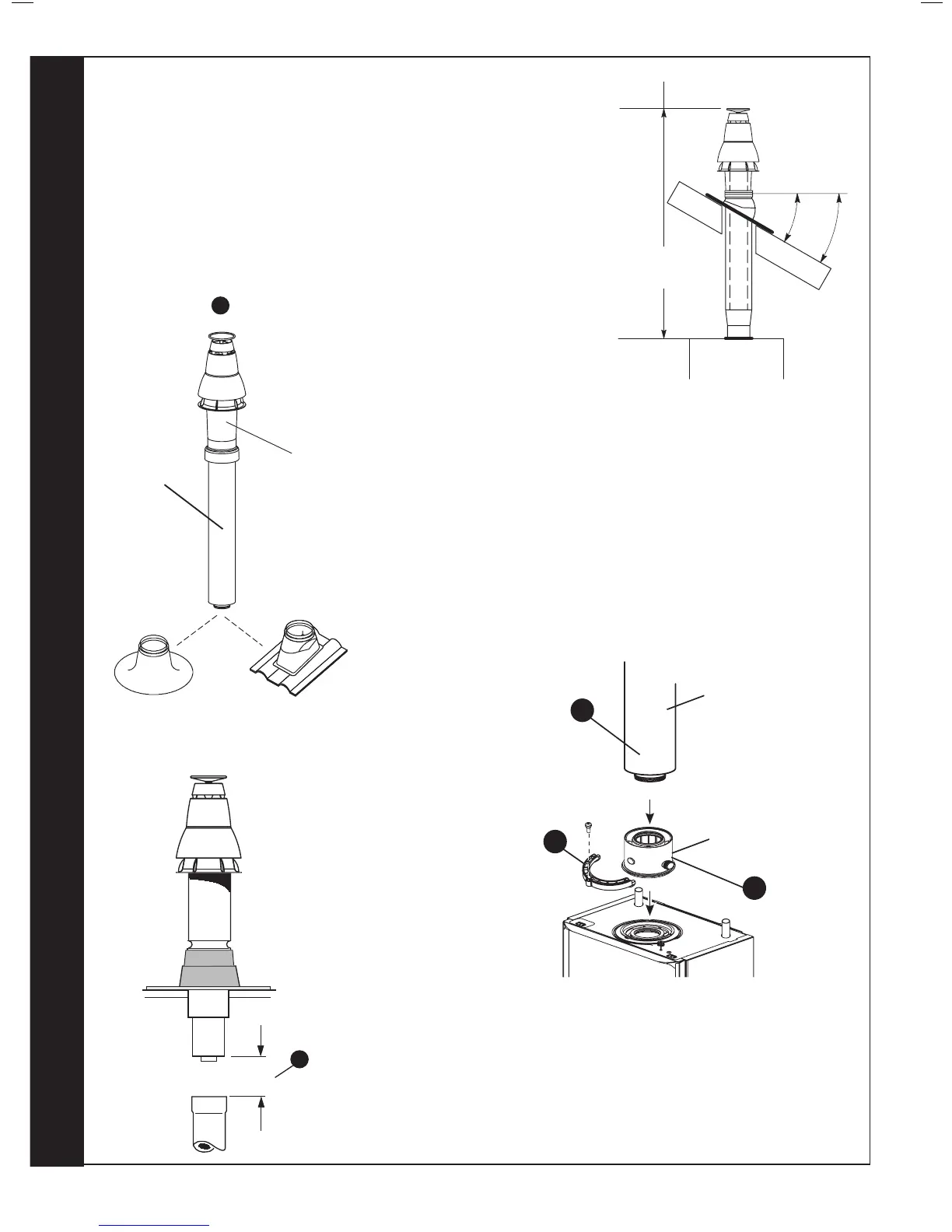

ASSEMBLING THE ROOF FLUE KIT

Determine the correct height that the ue should terminate

above the roof. If after calculating or measuring the overall ue

height from the top of the boiler, it is necessary to cut both pipes

of assembly A, then ensure they are cut equally leaving the inner

ue tube longer than the outer air tube as supplied.

Ensure the cut pipe ends are free from any burrs.

1. Position the roof ashing plate (supplied separately) over the

hole cut in the roof and insert ue terminal from the roof end.

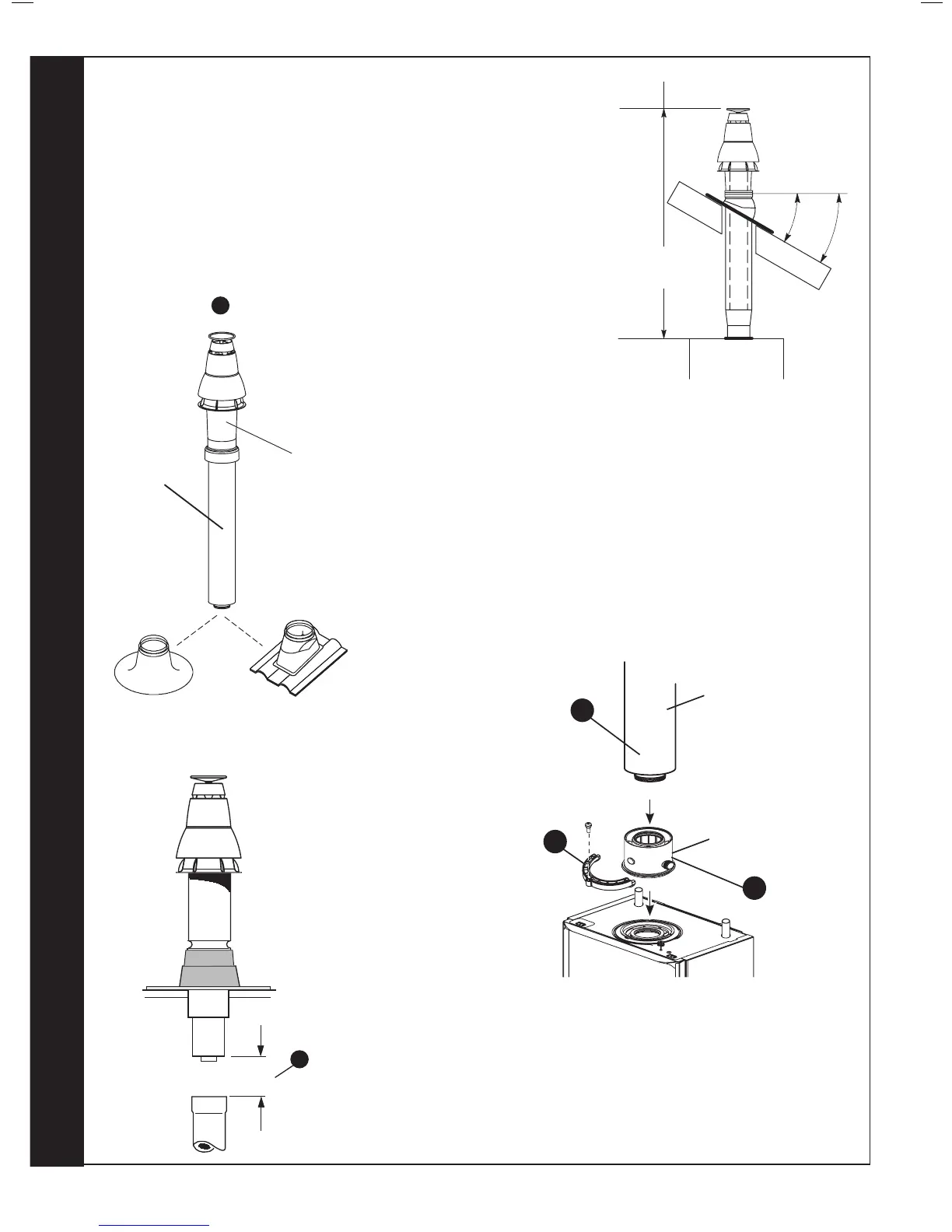

2. Fit the vertical connector (supplied in kit) in accordance with the

instructions provided with the vertical connector kit.

3. Secure the vertical connector by applying downward pressure

on the connector.

4. Position the clamp on the top face of the ue manifold and push

it horizontally backwards. Locate both clamp lugs into the ue

manifold and secure to the ue manifold with the M5 retaining

screw.

5. “Push” t extension duct (if required (supplied separately)) into

vertical connector.

Note. Ensure turret sample points are servicable and all caps and

plugs are tted. Fill the condense trap/siphon with water.

6. If the last extension duct requires cutting, measure ‘X’, the distance

(outer ducts), between the duct and the terminal and add 100 mm to this

dimension. This gives the length of the last extension duct.

Note. Check the position of the inner ue duct relative to the outer duct on

the assembled extension duct(s) and ensure the terminal ue duct is cut

longer than the air duct to ensure engagement in the nal ue duct seal.

7. Finally ensure the roof ashing plate is correctly sealed to the roof.

ASSEMBLY A

Loading...

Loading...