35

Installation and Servicing

Section 3 - Servicing

3.1 SERVICING SCHEDULE

Ensure all caps and seals are re-tted after use

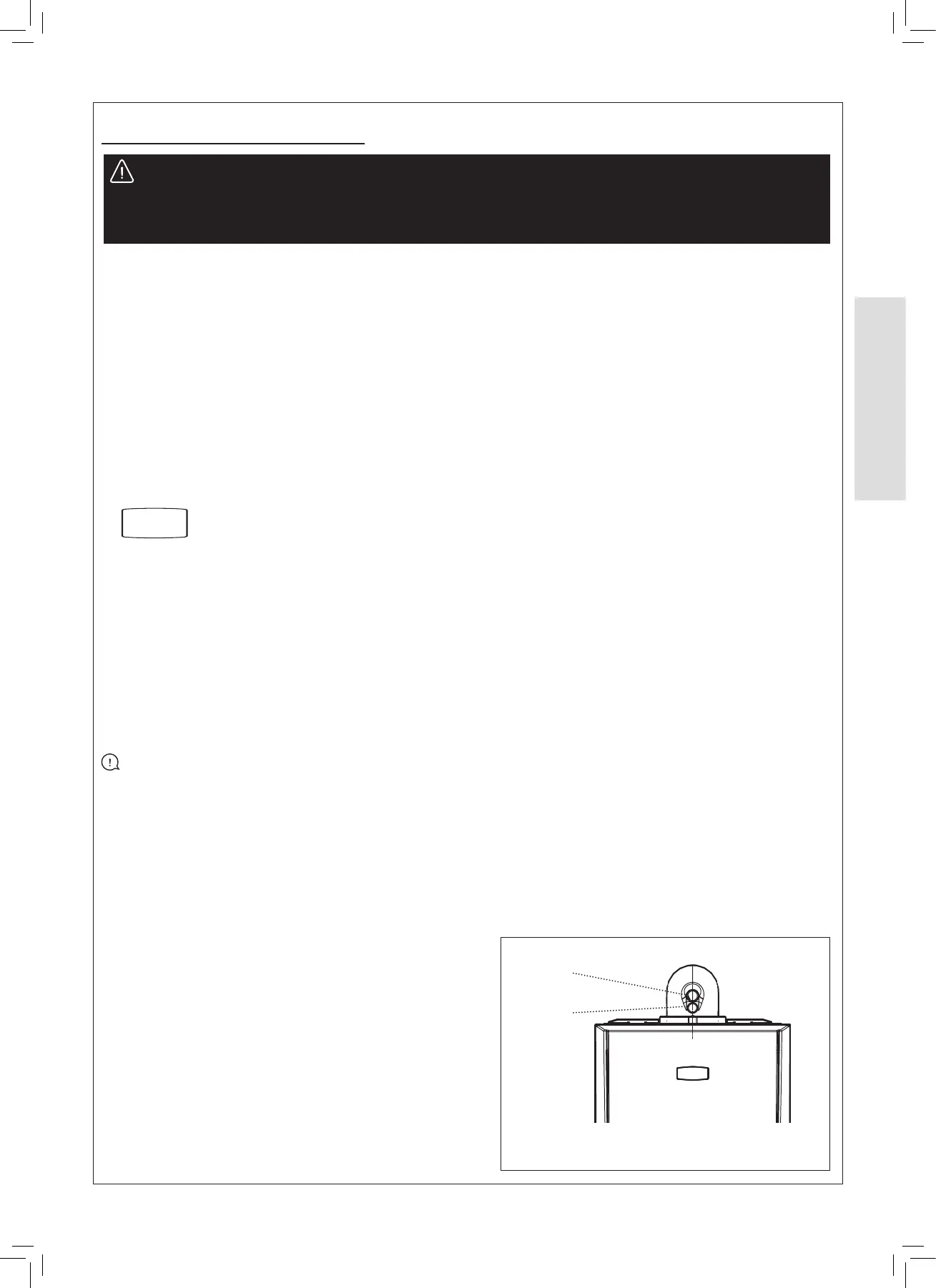

Air Sample

Point

Flue

Sampling

Point

To ensure the continued safe and ecient operation of the appliance it is recommended that it is checked at regular intervals

and serviced as necessary. The frequency of servicing will depend upon the installation condition and usage but should be

carried out at least annually.

For the latest copy of literature, visit our website idealheating.com.

WARNING: Servicing can only be carried out by Gas Safe Registered Engineers

Always turn OFF the gas supply at the gas service cock, and switch OFF and disconnect the electricity supply to the

appliance before servicing

Combustion testing must be carried out by a competent person using a combustion analyser conforming to

BS EN 50379-3:2012.

CLEANING PROCEDURE

1. Remove the casing.

2. Visually check the appliance for signs of leakage.

3. Remove the ue manifold.

4. Remove the fan.

5. Remove the burner.

6. Ret the sump outlet cover.

7. Clean the heat exchanger by pouring warm water across

the whole heat engine to ush deposits taking care to

avoid pouring water over the electrode.

8. Check the electrode for damage and clean using an

abrasive cloth. Check and adjust the spark gap. Replace

the electrode if damaged.

9. Clean out the sump outlet to ensure any debris is

removed.

10. Remove and clean the condensate trap and re- prime the

trap before re-installing.

11. Re-assemble the components in reverse order.

12. Carry out post service checks on the combustion circuit.

See General below.

13. Check the system water quality in accordance with

BS7593:2019.

14. Complete the service record in the Benchmark section.

Do not operate the boiler if the front panel is not tted.

PRELIMINARY INSPECTION

1. Light the boiler and carry out a pre-service check, refer to

the fault nding chart.

2. Check the ue terminal (and terminal guard if tted) for

damage and obstruction.

3. Check combustion by connecting the ue gas analyser to

the ue gas sampling point as shown in the diagram and

measure CO and CO

2

at maximum rate. Set the boiler to

Maximum and Minimum heat inputs.

Refer to Section

3.12

If the CO / CO

2

ratio is greater than 0.004 please proceed

to “Cleaning Procedure”.

If the CO / CO

2

ratio is less than 0.004 please proceed to

“Check Procedure”.

CHECK PROCEDURE

1. Check all water and gas joints for signs of leakage.

Remake any suspect joints ensuring a gas tightness

check is carried out if applicable and the water system is

correctly relled, vented and re-pressurised.

2. Proceed to “IMPORTANT”.

IMPORTANT

1. If, for any reason, the condensate trap has been removed,

ensure the trap is relled with water before re-assembling.

2. After completing the servicing or exchange of components

always ensure all gas valve connections are gas tight with

a gas soundness check up to the gas control valve.

3. When work is complete the front panel MUST be correctly

retted, ensuring that a good seal is made.

4. Complete the service section in the Benchmark

Commissioning Checklist.

GENERAL

During Servicing, and after any maintenance or change of

part of the combustion circuit, the following must be checked:

- The integrity of the ue system and the ue seals.

- The integrity of the boiler combustion circuit and the

relevant seals.

- The operational (working) gas inlet pressure at maximum

rate.

- The gas rate.

- The combustion performance.

Loading...

Loading...