B

23

B

23

B

23

B

23

1

2

3

4

1

2

3

20 21

22 23

20

INSTALLER

USER

MAINTENANCE TECHNICIAN

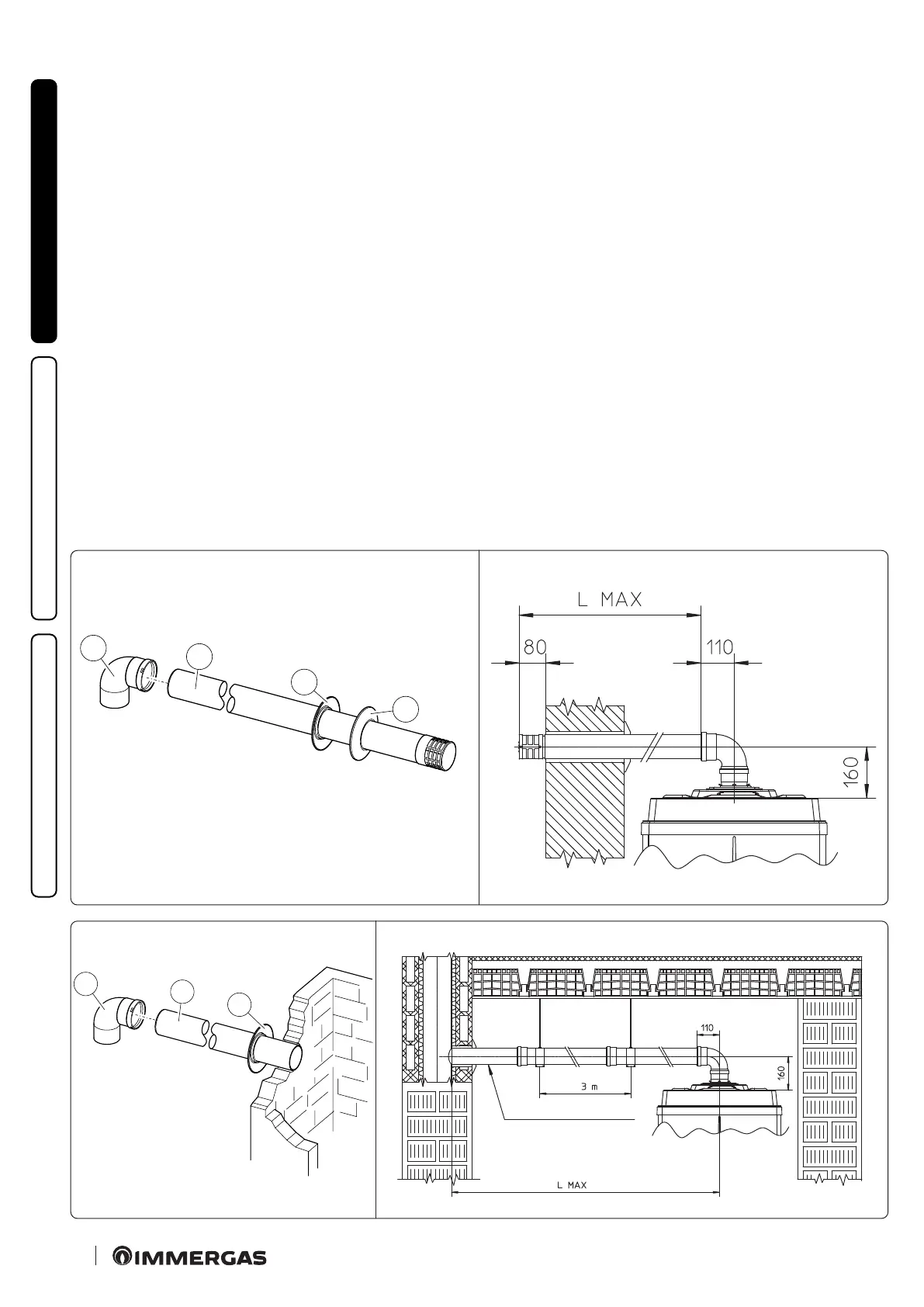

1.18 INSTALLATION OF 80 Ø HORIZONTAL

TERMINALS.

Conguration type B, open chamber and forced draught.

Ø 80 horizontal kit with wall ue exhaust.

Kit assembly (Fig. 20): install the 80 Ø bend (1) with the male

side (smooth) fully home on the central hole of the boiler. Fit the

exhaust terminal (2) with the male end (smooth) to the female end

of the bend (1) up to the stop; making sure that the internal (3)

and external (4) wall sealing plate has been tted. is will ensure

sealing and joining of the elements making up the kit.

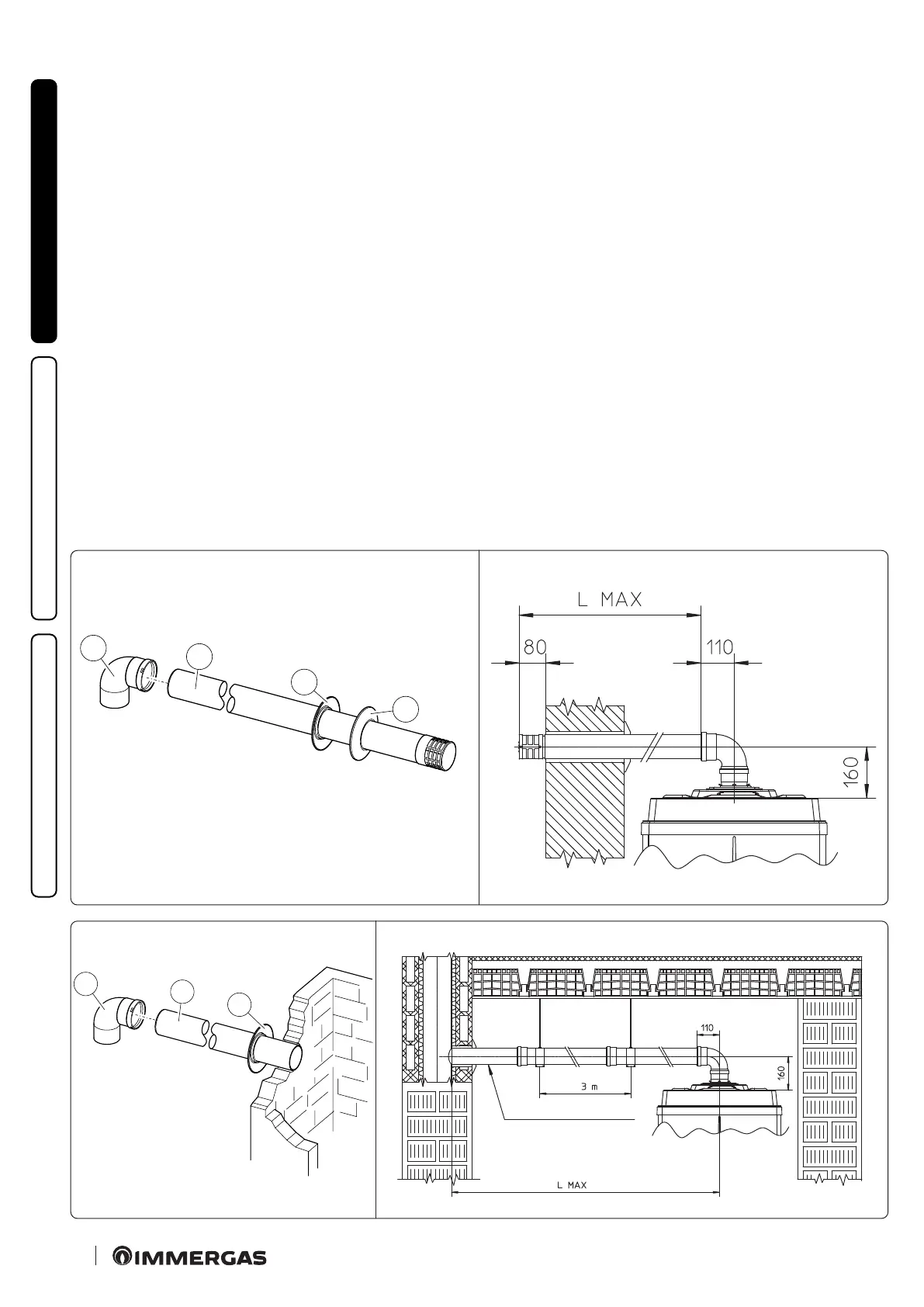

Horizontal kit Ø 80 with exhaust in ue. Kit assembly (Fig. 22):

install the 80 Ø bend (1) with the male side (smooth) fully home

on the central hole of the boiler. Fit the exhaust pipe (2) with

the male end (smooth) to the female end of the bend (1) up to

the stop; making sure that the internal wall sealing plate (3) has

been tted. is will ensure sealing and joining of the elements

making up the kit.

• Maximum length (MAX L) (Fig. 21 and 23). e kit with this

conguration can be extended up to a max. measurement of 28.0

m with Victrix Pro 80 2ErP, 14.0 m with Victrix Pro 100 2ErP

and 8.5 m with Victrix Pro 120 2ErP, including the terminal.

e kit includes:

N° 1 - Bend 90° Ø 80 (1)

N° 1 - 80 Ø exhaust terminal (2)

N° 1 - Internal ring (3)

N° 1 - External ring (4)

e kit includes:

N° 1 - 90° 80 Ø bend (1)

N° 1 - 80 Ø drain pipe (2)

N° 1 - Internal ring (3)

Minimum gradient 1.5 %

Loading...

Loading...