22204911 Rev. E EN-11

EN

Disconnect wire from engine spark plug and release

air pressure from the tank before performing

maintenance.

NOTICE

All compressed air systems contain maintenance

parts (e.g. lubricating oil, lters, seperators) which are

periodically replaced. These used parts may be, or may

contain, substances that are regulated and must be

disposed of in accordance with local, state, and federal

laws and regulations.

NOTICE

Take note of the positions and locations of parts

during disassembly to make reassembly easier. The

assembly sequences and parts illustrated may dier

for your particular unit.

NOTICE

Follow engine owner’s manual for engine maintenance

schedules and procedures.

NOTICE

Any service operations not included in this section

should be performed by an authorized service

representatives.

PERIOD MAINTENANCE

Daily or before

each operation

Check lubricant level. Fill as needed.

Drain reciever tank condensate. Open

the manual drain valve and collect,

dispose condensate accordingly.

Check for unusual noise and vibration.

Ensure beltguards and covers are

securely placed.

Ensure area around compressor is free

from rags, tools, debris, and ammable

or explosive materials.

Weekly/

Monthly

Inspect air lter element. Clean/Replace

if necessary.

Inspect for air leaks. Squirt soapy water

around joints during compressor

operation and watch for bubbles.

Check tightness of screws and bolts.

Tighten as needed.

3/500*

12/2000*

Clean exterior.

Change petroleum lubricant while

crankcase is warm.

Change synthetic lubricant while

crankcase is warm.

Replace lter element.

* - indicates months/operating hours, whichever occurs rst

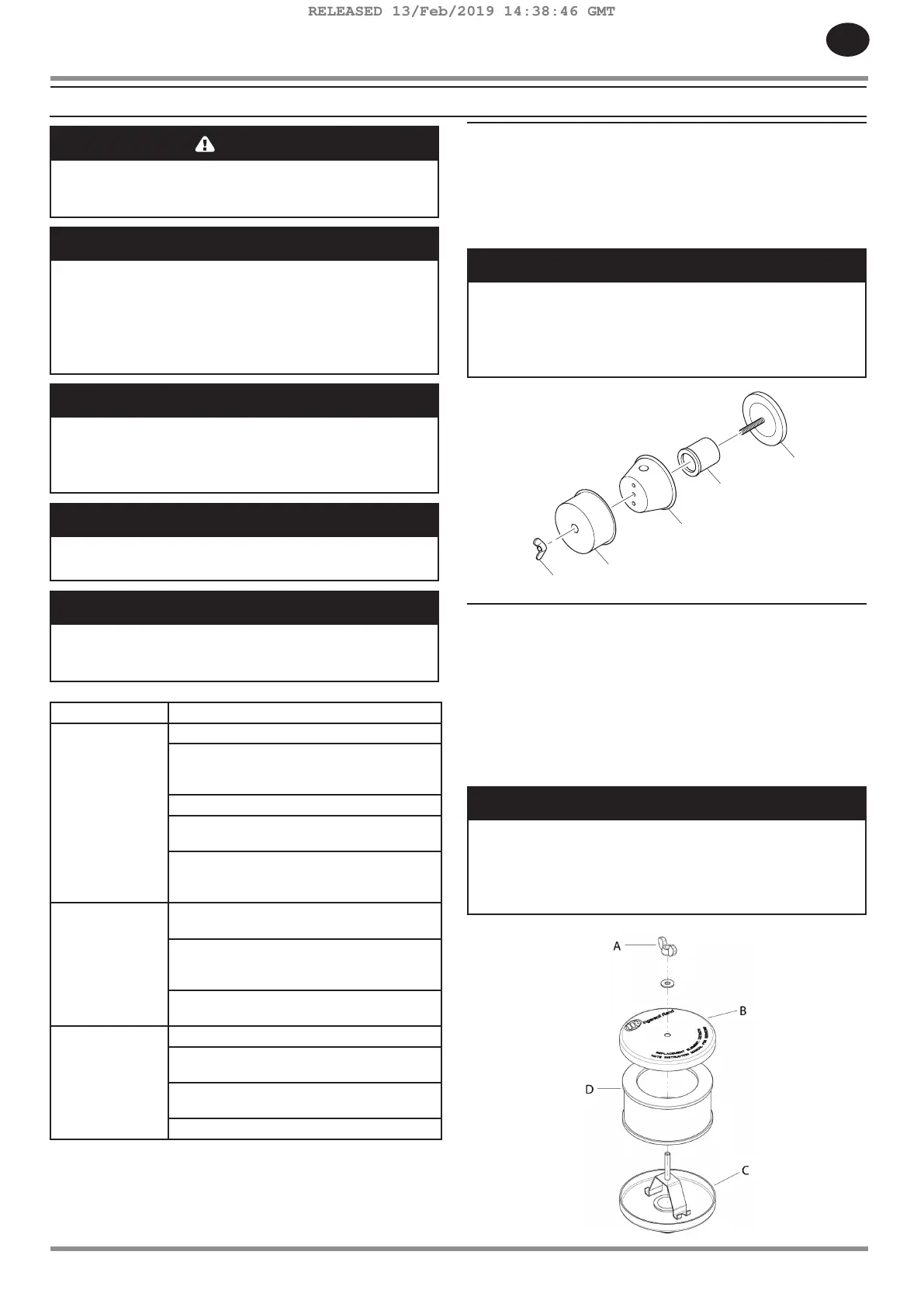

FILTER REPLACEMENT (SS3)

1. Unscrew and remove the wing-nut (A).

2. Remove the lter cover (B), bae (C) and element (D)

from the base (E).

3. Install a new element and reassemble the lter assembly.

NOTICE

The air intake holes in the bae and cover must be

staggered 180°. When reinstalling the assembly at the

inlet connection, ensure the intake hole in the cover is

on the bottom to minimize the entry of foreign matter

from the air.

B

C

D

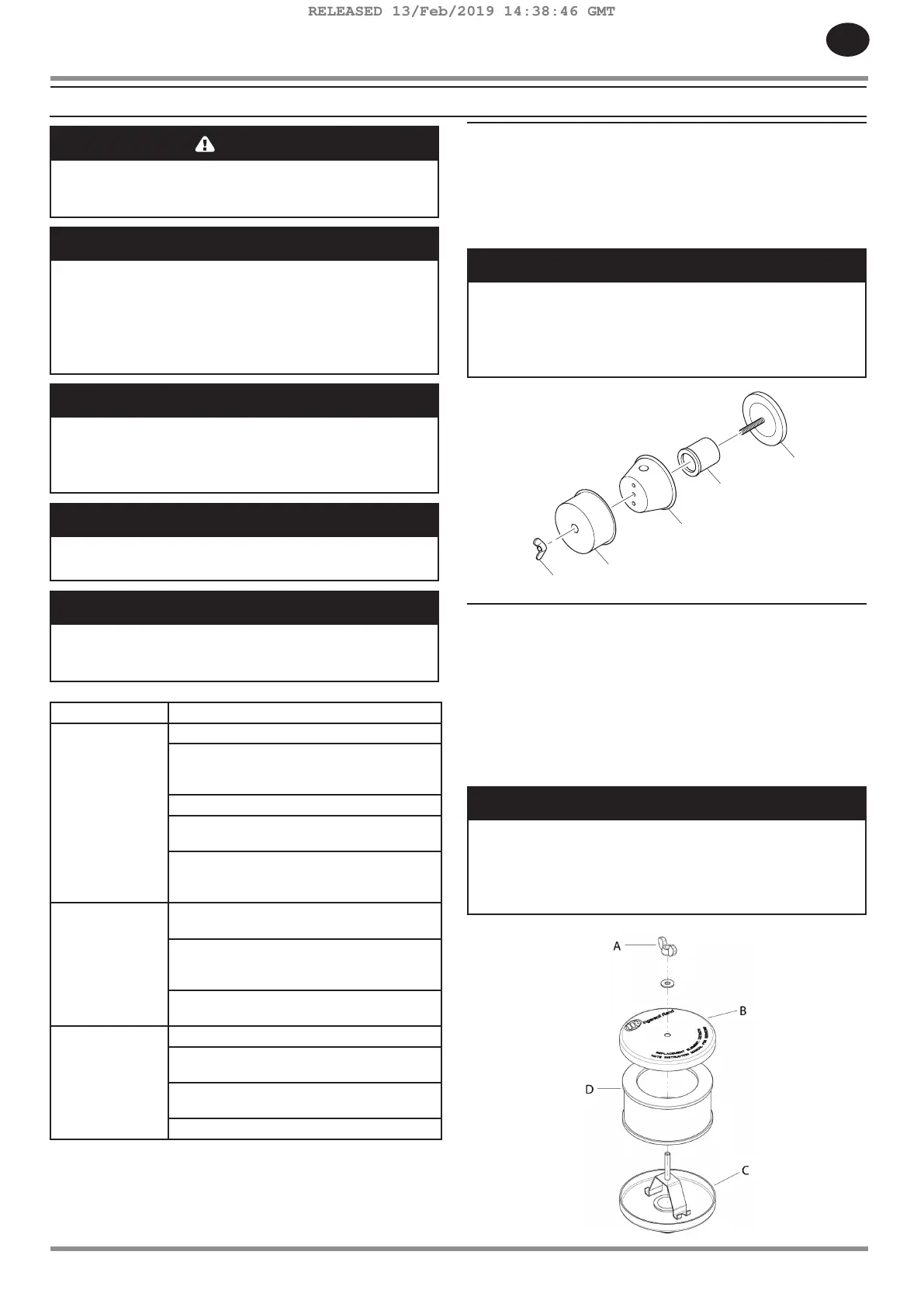

FILTER REPLACEMENT (SS5)

1. Unscrew and remove the wing nut (A) securing the lter

housing (B) to its base (C).

2. Remove the lter busing and withdraw the old lter

element (D) Clean the element with a jet of air or

vacuum.

3. Replace the lter element and housing, securing it in

place with the wing nut previously removed.

NOTICE

The air intake holes in the bae and cover must be

staggered 180°. When reinstalling the assembly at the

inlet connection, ensure the intake hole in the cover is

on the bottom to minimize the entry of foreign matter

from the air.

MAINTENANCE

RELEASED 13/Feb/2019 14:38:46 GMT

Loading...

Loading...