EN

EN-6 22204911 Rev. E

SELECTING A LOCATION

GENERAL

Select a clean, dry, well-lighted area with plenty of ventilation

proper cooling air ow and accessability. Locate the unit

atleast 12 inches (30 cm) from walls. Ensure that the unit is as

level as possible to avoid fuel spillage.

TEMPERATURE

Ideal operating temparatures are between

40 °F to 100 °F (4 °C to 37.8 °C). In lower temperatures, you

must protect safety/relief valves and drain valves from

freezing.

HUMID AREAS

In frequently humid areas, moisture may form in the bare

pump and produce sludge in the lubricant, causing running

parts to wear out prematurely. Excessive moisture is especially

likely to occur if the unit is located in an unheated area

that is subjected to large temperature changes. Two signs

of excessive humidity are external condensation on the

bare pump when it cools down and a “milky” appearance in

petroleum compressor lubricant. You may be able to prevent

moisture from forming in the bare pump by increasing

ventilation or operating for longer intervals.

NOISE CONSIDERATIONS

Consult local ocials for information regarding acceptable

noise levels in your area. To reduce excessive noise, use

vibration mounts or intake silencers, relocate the unit or

construct total enclosure or bae walls. Consult your dealer

for assistance.

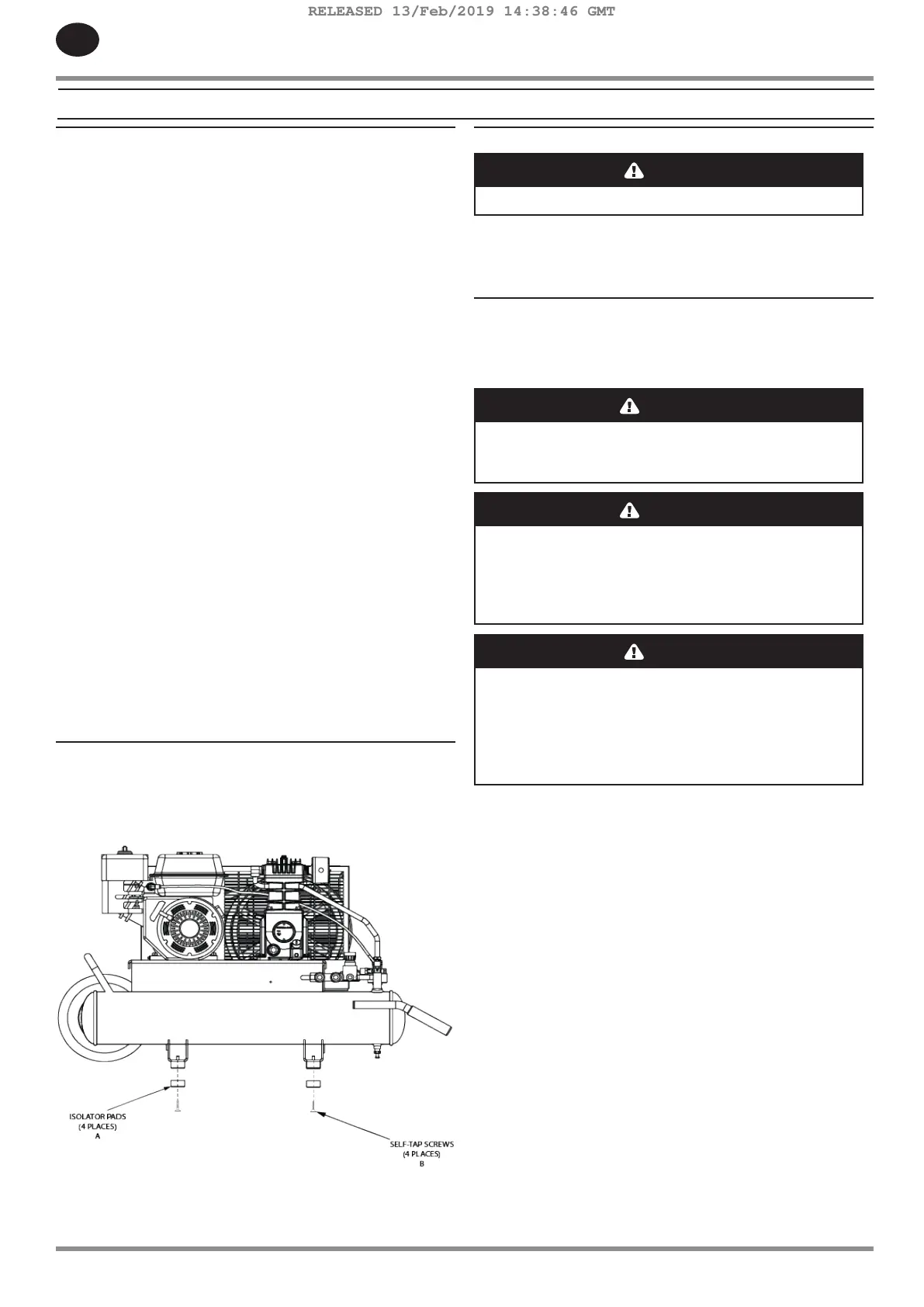

INSTALLING THE ISOLATOR PADS

1. Install isolater pads (A) on all four feet with self-tap

screws (B).

2. Hand tighten screws.

INSTALLING THE INLET AIR FILTER

Do not operate without air inlet lter.

Install the air inlet lter at the inlet connection at the bare

pump. If heavy duty lteration is required, contact your dealer

for information.

INSTALLING DISCHARGE PIPING

If it is necessary to install air discharge piping or condensate

discharge piping, adhere to the following general guidelines.

Contact your dealer for more information.

WARNING

Do not use plastic pipe, rubber hose or lead-tin

soldered joints anywhere in the compressed air

system.

If an after-cooler, check valve, block valve, or any

other restriction is added to the compressor discharge,

install a properly-sized ASME approved safety/relief

valve between the compressor discharge and the

restriction.

If you will be using Ingersoll Rand Synthetic

Lubricant all downstream piping material and

system components must be compatible. Refer to the

following compatability list. If there are incompatible

materials present in your system, or there are

materials not included in the list, contact your dealer.

INSTALLATION

RELEASED 13/Feb/2019 14:38:46 GMT

Loading...

Loading...