- 147 -

6 Inspection and Maintenance

6

Chapter 6 Inspection and Maintenance

The influence of the ambient temperature, humidity, dust and vibration will cause aging of components

inside the controller, which may cause potential faults or reduce the service life of the controller. Therefore,

it is necessary to carry out routine and periodic inspection.

More frequent inspection is required if the equipment is used in harsh environments, such as:

● High ambient temperature

● Frequent startup and stop

● Fluctuations in the AC power supply or load

● Excessive vibrations or impact

● Dust, metal dust, salt, sulfuric acid, chlorine atmospheres

● Poor storage conditions

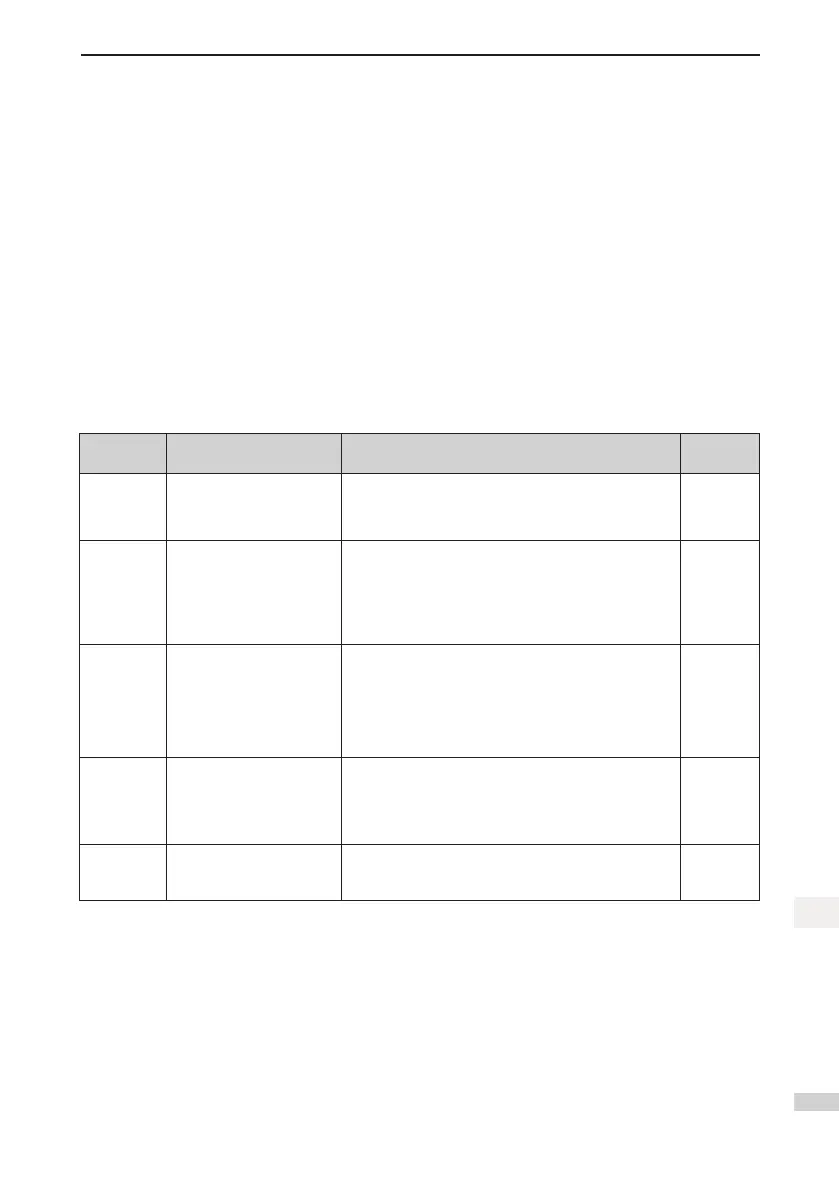

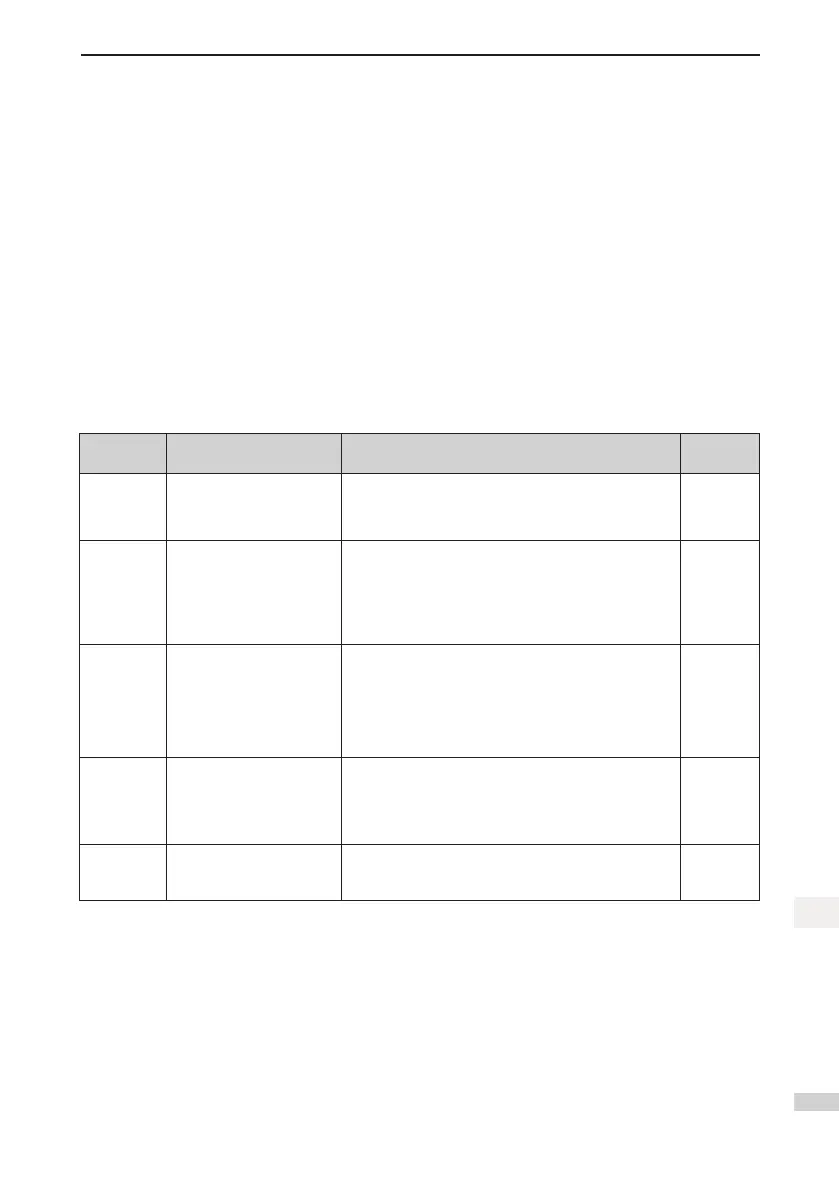

Check the following items daily to avoid deterioration in performance or product failure. Copy this checklist

and sign the “checked” column after each inspection.

Inspection

Item

Inspection Points Correction Checked

Motor

Check whether abnormal

oscillation or noise exists.

• Check the mechanical connection.

• Check the power phases of the motor.

• Tighten all loose screws.

Cooling fan

Check whether the cooling

fans of the controller and

the motor work abnormally.

• Check running of the cooling fan of the controller.

• Check running of the cooling fan of the controller.

• Check whether the air lter is clogged.

• Check whether the ambient temperature is within the

allowable range.

Installation

environment

Check whether the

cabinet and cable duct are

abnormal.

• Check whether insulation of the input and output

cables is damaged.

• Check whether there is shock to the supporting

bracket.

• Check whether the copper bar and terminals are

loose and corroded.

Load

Check whether the

controller output current

exceeds the controller

rating and motor rating for a

certain time.

• Check for setting of motor parameters.

• Check for excessive load.

• Check for mechanical vibration (< 0.6 g on normal

condition).

Input

voltage

Check the main power

supply and the control

voltage.

• Adjust the input voltage to the allowable range.

• Check for starting of heavy load.

Loading...

Loading...