- 44 -

2 System Commissioning

2

Angle-free Auto-tuning

Related parameters

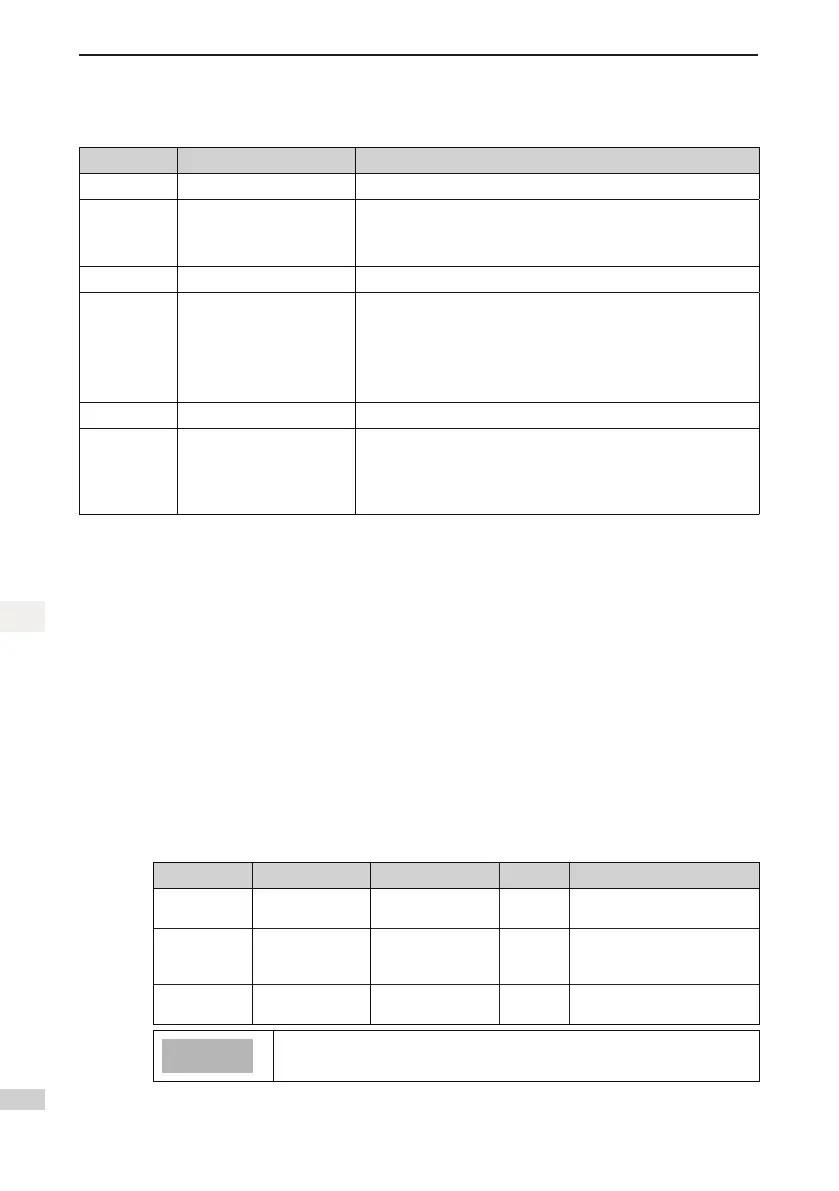

Parameter No. Parameter Name Value

F1-25 Motor type 1: Synchronous motor

F1-00

Encoder type 0: SIN/COS encoder

1: UVW encoder

3: Endat absolute encoder

F1-12 Encoder resolution 0 to 10000

F1-01 to F1-

05

Motor rated power

Motor rated voltage

Motor rated current

Motor rated frequency

Motor rated speed

These parameters are model dependent, and you need to

manually input them according to the nameplate.

F0-01 Command source selection 1: Distance control

F1-22

Angle-free auto-tuning

selection

2: Half automatic, angle-free auto-tuning at rst-time running after

power-on and power-off, only in inspection state

6: Full automatic, angle-free auto-tuning at rst-time running after

power-on and power-off, both in inspection and automatic states

2.2.3 Shaft Auto-tuning

1. Make preparations for shaft auto-tuning.

1) Check that the shaft switches act properly, including nal limit switches, limit switches, slow-

down switches, and leveling sensors.

2) Check that the acting sequence of the leveling sensors is correct.

Generally, one leveling sensor is installed. If multiple leveling sensors are installed, check that

the acting sequence is correct. Take the situation with three sensors as an example:

Acting sequence of sensors at inspection up: up leveling sensor → door zone sensor → down

leveling sensor

Acting sequence of sensors at inspection down: down leveling sensor → door zone sensor →

up leveling sensor

3) Check CANbus communication state. If fault E51 is not reported and the COP indicator on the

MCB is steady ON, it indicates that CANbus communication between the MCB and the CTB

is normal. If CANbus communication is abnormal, rectify fault E51 according to the solution

described in Chapter 9.

4) Set the related parameters.

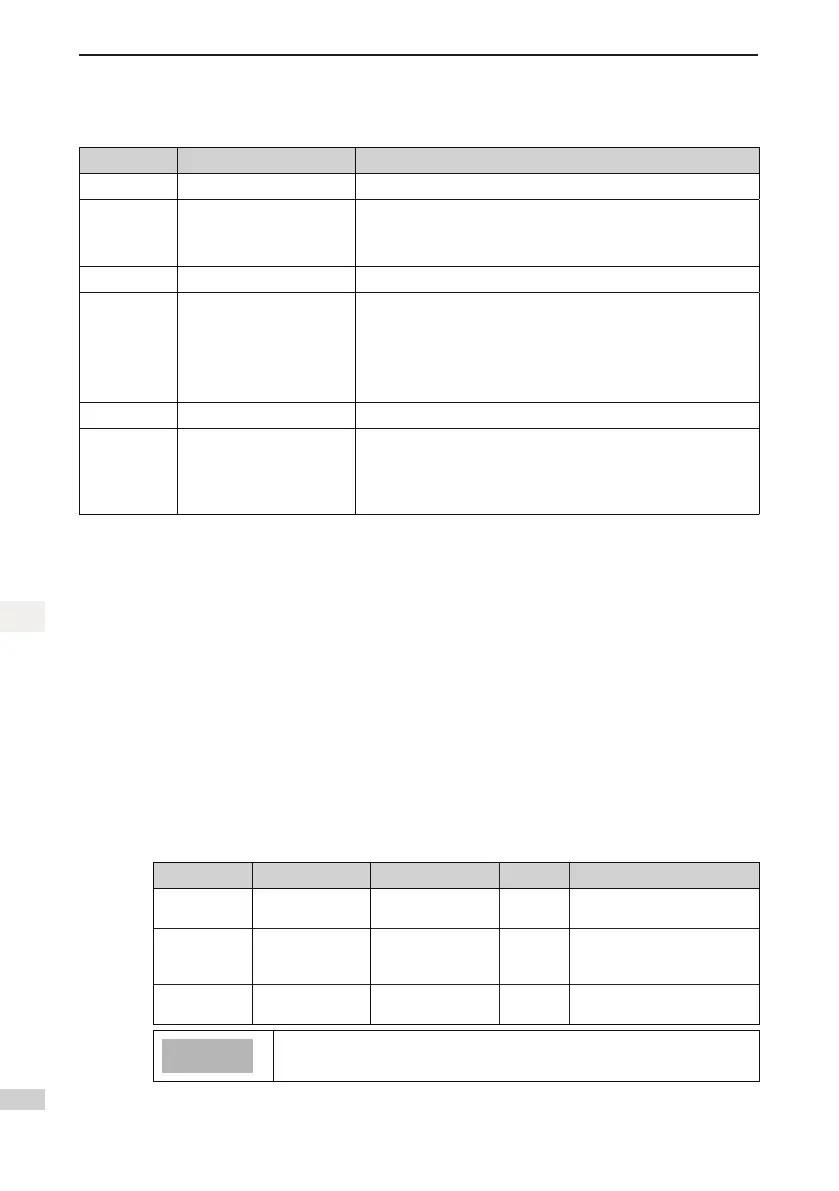

Parameter No. Parameter Name Setting Range Default Remarks

F0-04

Rated elevator

speed

0.250 to 8.000 m/s 1.600 m/s -

F6-00

Top oor of the

elevator

F6-01 to 56 9

Set it to the actual number

of oors (number of actually

installed leveling plates).

F6-01

Bottom oor of

the elevator

1 to F6-00 1 -

Shaft auto-tuning is required each time F0-04 is changed. Otherwise, the

elevator running will be abnormal.

Loading...

Loading...