5-23

INSPECTION AND MAINTENANCE

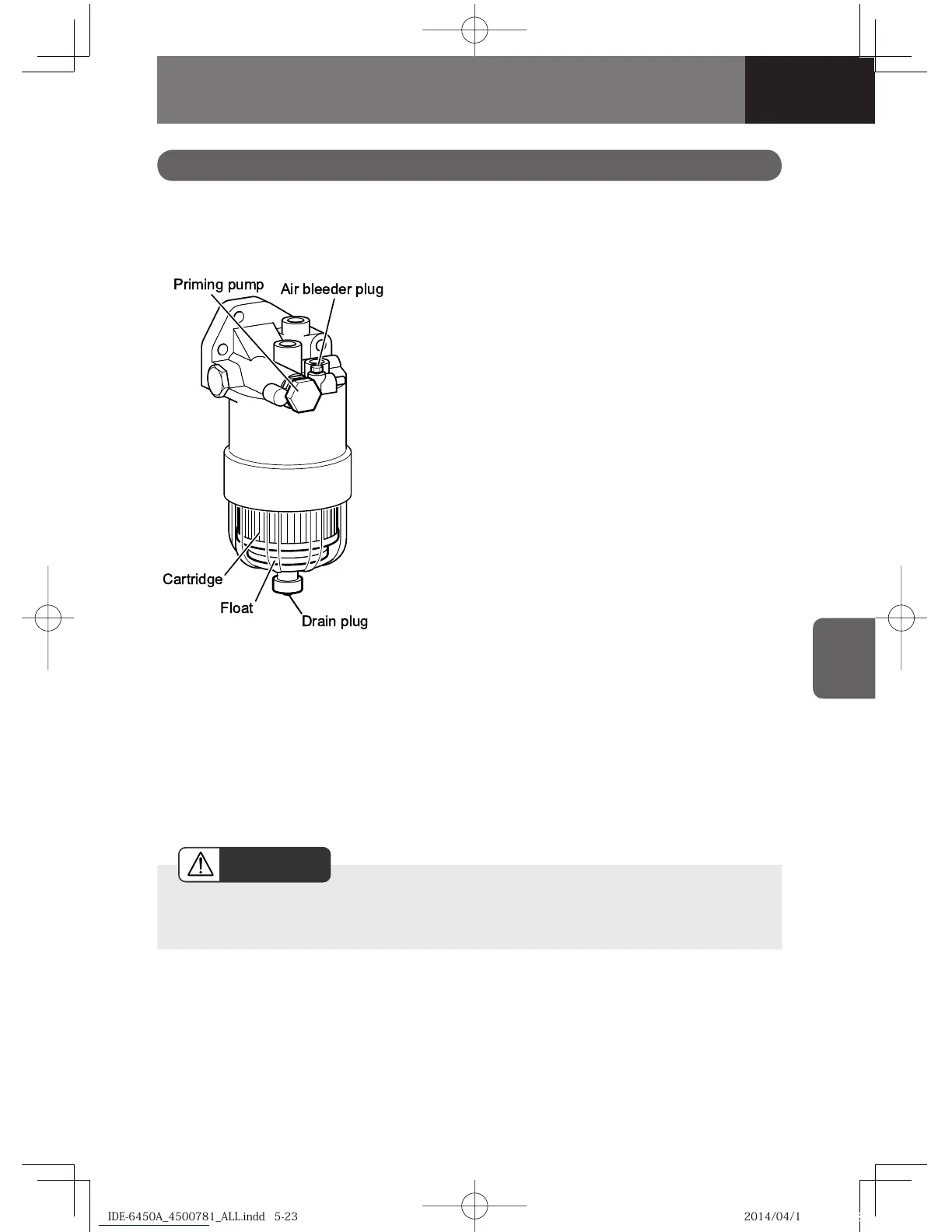

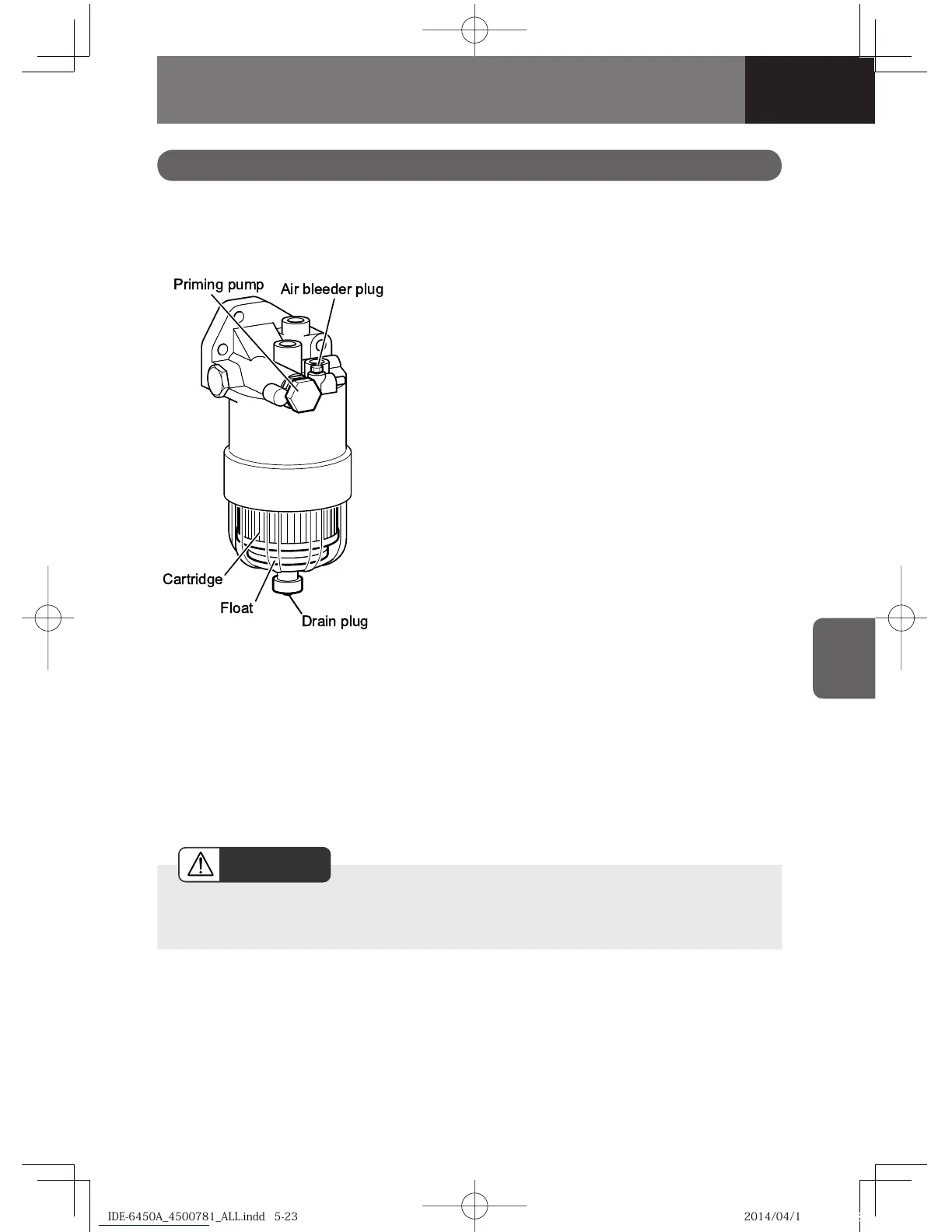

Bleeding the Fuel System

When air mixes into the fuel system, this can cause a difficulty in engine starting or

engine malfunction. When the fuel tank is emptied, or when water removal from fuel

or filter element replacement is performed, make sure to carry out air removal.

1. Turn the starter switch to "DRIVE" position,

and activate the electromagnetic pump, etc.

2. Loosen the air bleeder plug of the fuel filter

sufficiently, and operate the priming pump

until the fuel comes out.

3. Tighten the air bleeder plug and operate the

priming pump 10 times or more until the fuel

filter is filled with fuel.

4. Wait for approx. 1 minute, and loosen the air

bleeder plug to remove the air from the fuel

filter.

5. Repeat Steps 2 through 4 at least 3 times

until air does not come out from the air

bleeder plug.

6. Securely tighten the air bleeder plug, and

wipe off the fuel spread around.

7. Start the engine without manipulating the

engine speed on the machine side. If the

engine does not start at this time, repeat the

procedure from Step 3.

8. After the engine has started, allow it to idle

for 5 seconds.

9. Slowly raise the engine speed, and maintain the status for 3 minutes.

10. Raise the engine speed up to the maximum speed, and then decrease it to the

idle speed.

11. Repeat Steps 8 through 10 several times.

WARNING

Start the engine to inspect for a leakage in the fuel system. A leakage can

cause a fire.

•

Air bleeder plug

Priming pump

Cartridge

Float

Drain plug

Air bleeder plug

Priming pump

Cartridge

Float

Drain plug

IDE-6450A4500781ALL.indd5-23IDE-6450A4500781ALL.indd5-23 2014/04/1814:20:032014/04/1814:20:03

Loading...

Loading...