6

INSTALLATION

Safety precautions

See the “Care and Maintenance” for the appropriate

pump.

Mounting the flush valve on the

pump

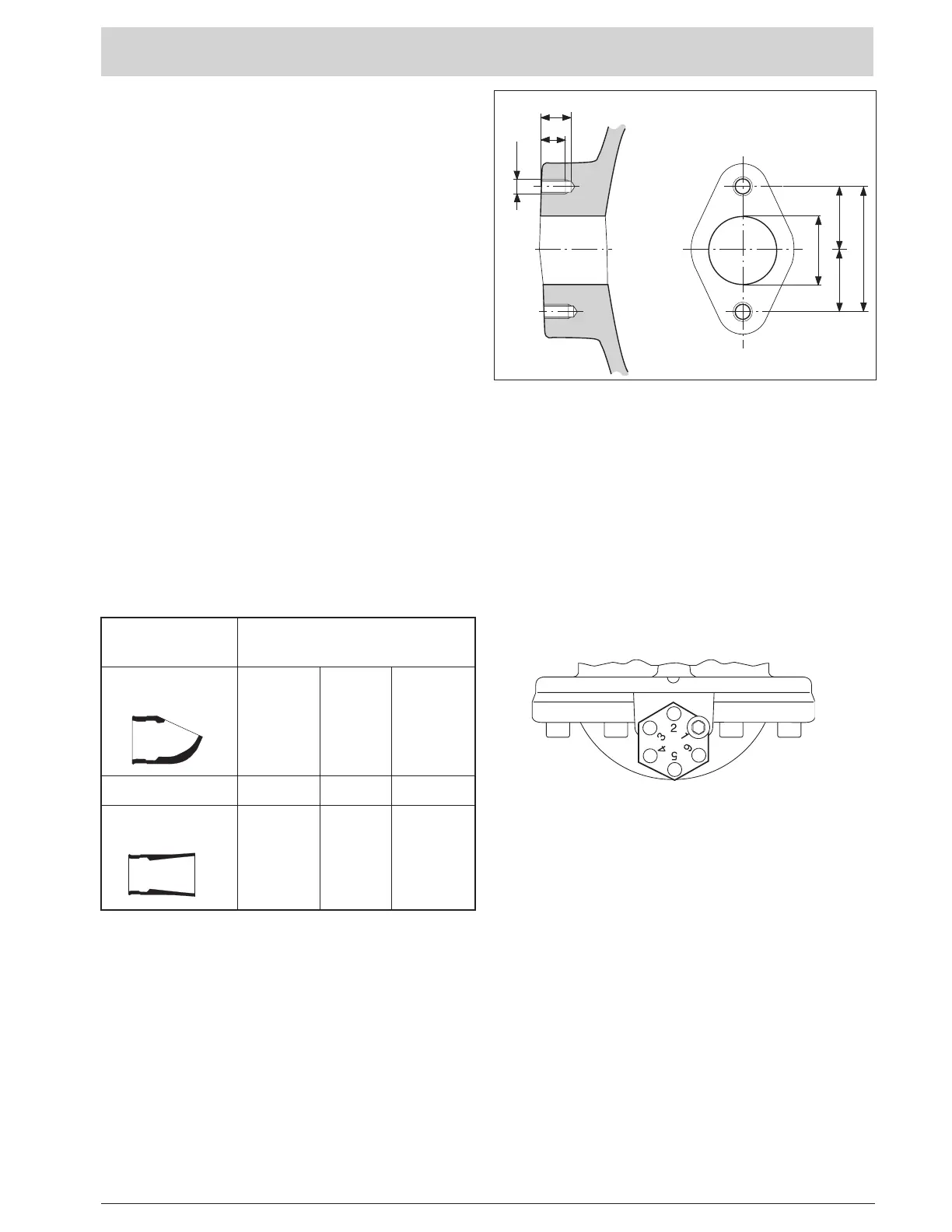

The pump housings are pre-drilled and must be

equipped with a cast flat for the flush valve connection.

The drilling pattern is shown in Figure B. For further in-

formation, contact your nearest Flygt representative.

Setting flushing time

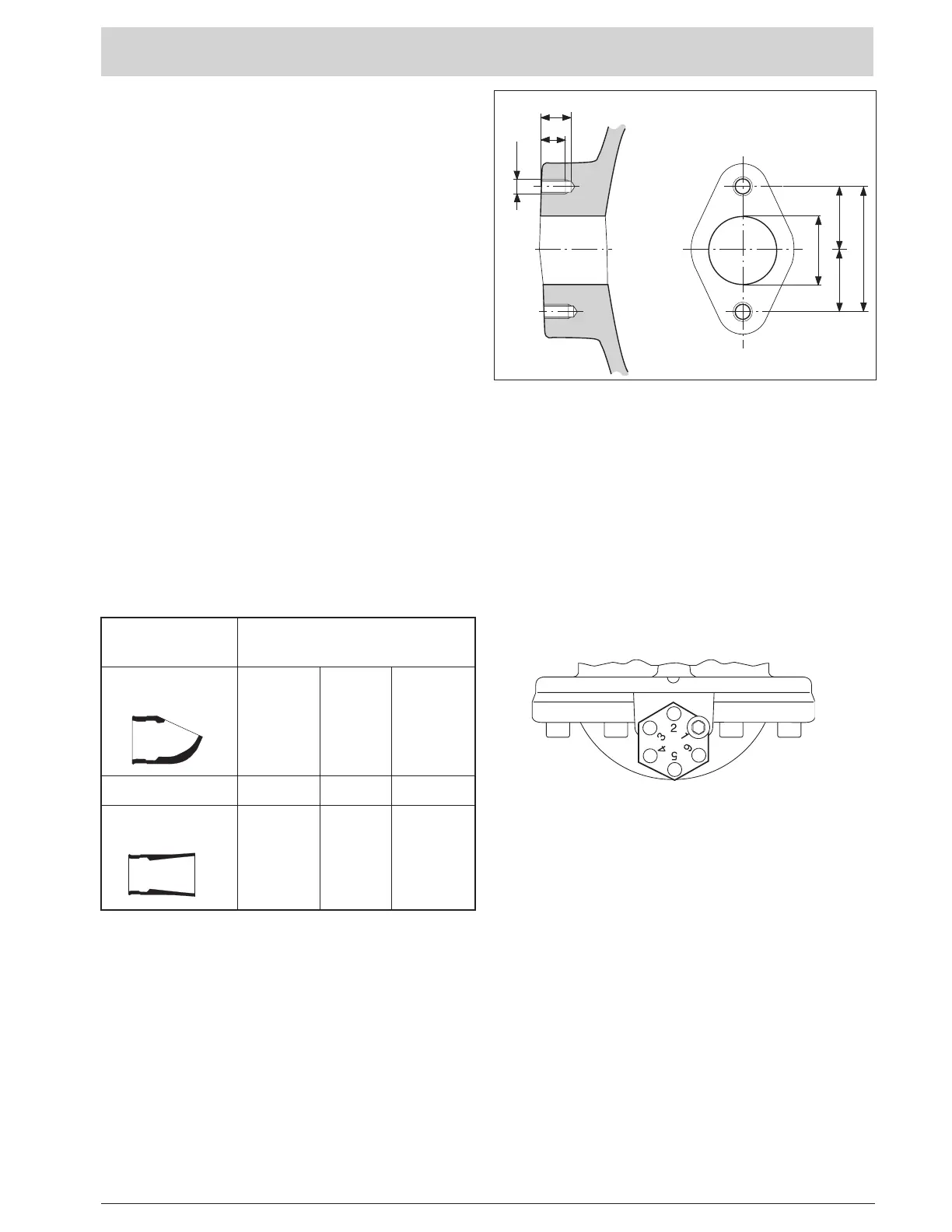

The 4901 flush valve is designed to support the three

possible executions;

1) with outlet bend

2) with outlet pipe

3) execution

without

outlet bend and

without

outlet

pipe is called “short outlet”.

The flushing time is determined by the regulating valve.

The delivery setting is “2”.

Recommended

approximative

first setting of the

regulating valve:

Execution Geodetic Pump Head (m).

< 4 4–10 > 10

Outlet bend

586 68 00 1 2 3

Short outlet 2 3 3–4

Outlet pipe

558 08 00 2 3 4

The recommended flushing period is 20 seconds.

Note. The flushing time for the special version may

vary more than for the standard version.

“Setting 2”

For a

shorter

flushing period, turn the regulating valve

to a

lower

setting.

Lock the regulating valve with the locking screw.

Note:

The flushing period is also affected by the oil viscosity

(the temperature of the water or of the air) and of the

underpressure in the valve body. The outlet pipe gives

the best underpressure and the outlet bend gives the

poorest underpressure. Therefore – be aware of the

limits!

Note. If the flush valve 4901 is used with the APF, a

maximum flushing period of 45 seconds should not

be exceeded.

Adjusting the regulating valve

Loosen the locking screw.

For a

longer

flushing period, turn the regulating valve

to a

higher

setting.

23

18

84

42

42

M 10

ø 46

Figure B

Loading...

Loading...